Wireless product production testing devices and wireless product production testing system

A production testing and product technology, applied in the field of wireless product production testing devices and systems, can solve the problems of difficult development, high cost and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

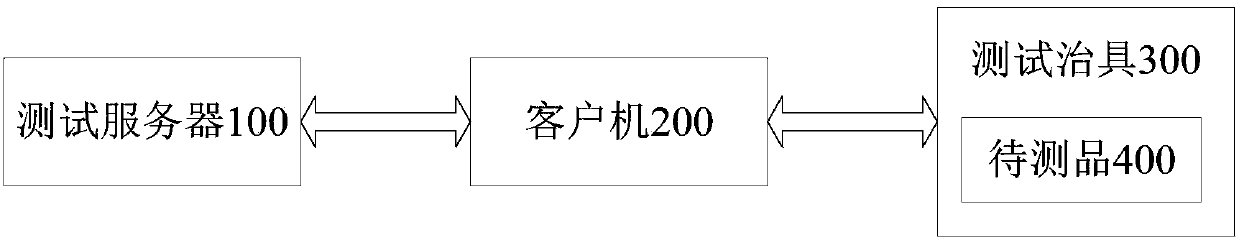

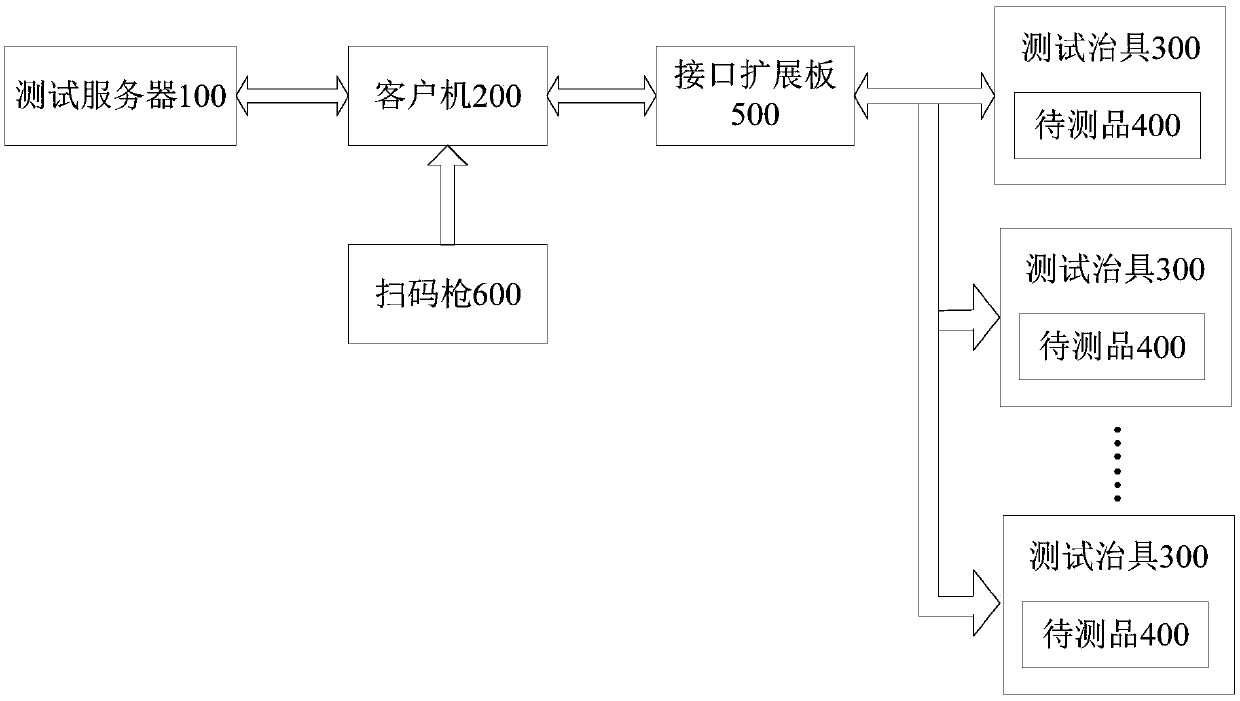

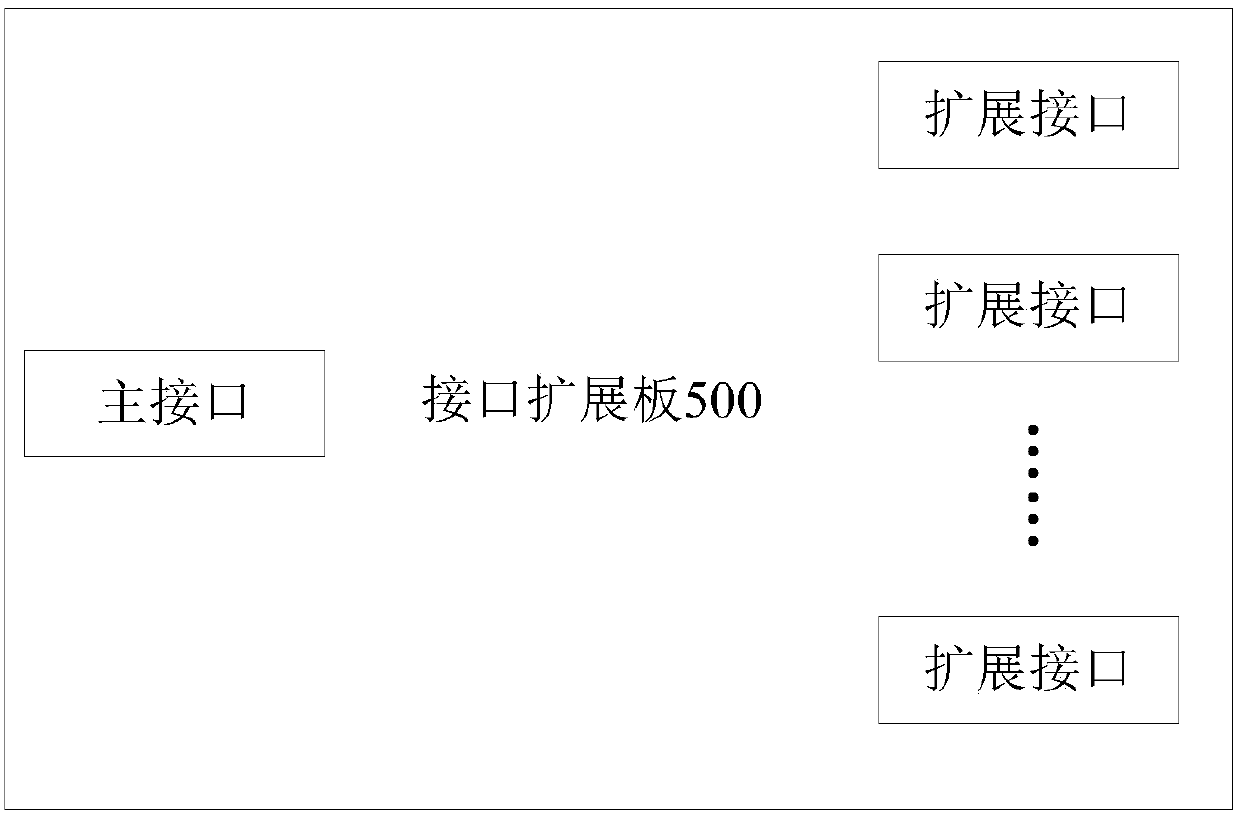

[0041] figure 1 It shows a first structural schematic diagram of a wireless product production and testing device provided by an embodiment of the present invention. Such as figure 1 As shown, the wireless product production test device includes: a test server 100, a client 200, and a test fixture 300, wherein the test fixture is used to place and fix a test product 400.

[0042] The above-mentioned test server is connected to the client, sends test instructions to the client, and receives the test result sent by the client.

[0043] Specifically, a software system for wireless product production testing is deployed on the test server, which can realize access control to the client, and adopts a lightweight database system for data storage, which is simple to deploy.

[0044] A browser is installed on the client, through which the browser establishes a connection with the test server, establishes a connection with the DUT according to the received test instruction, sends the test ins...

Embodiment 2

[0061] Figure 4 It shows a third structural schematic diagram of the wireless product production and testing device provided by the embodiment of the present invention. The difference between the wireless product production test device and the first embodiment is that it runs the role of the client in the test server, so that no additional smart terminals are needed, and it is mainly applied to small-scale enterprises such as a single production line.

[0062] Therefore, the wireless product production test device in the present invention includes: a test server 100 and a test fixture 300, wherein the test fixture is used to place and fix the product under test. A browser is installed on the test server. The browser obtains the test instructions generated by the test server, establishes a connection with the test product according to the test instructions, sends the test instruction to the test product, and receives the test result returned by the test product.

[0063] In the act...

Embodiment 3

[0068] Image 6 Shows a schematic structural diagram of a wireless product production test system provided by an embodiment of the present invention, such as Image 6 As shown, the wireless product production test system includes a management server 700, a product to be tested 400, and a wireless product production test device 800 as in the first or second embodiment.

[0069] The product under test is used to execute the test instruction of the wireless product production test device, and return the test result to the wireless product production test device. The management server is used to receive and store the test results periodically sent by the wireless product production test device.

[0070] Specifically, when the wireless product production test system is applied to a small-scale enterprise, such as a small-scale enterprise with a single production line, the wireless product production test device in the second embodiment can be selected; when the wireless product product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com