A kind of perc crystalline silicon solar cell back passivation silver paste with high back pull force and anti-cracking and preparation method thereof

A solar cell, crystalline silicon technology, applied in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve problems such as no PERC paste, and achieve superior electrical performance, low production cost, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

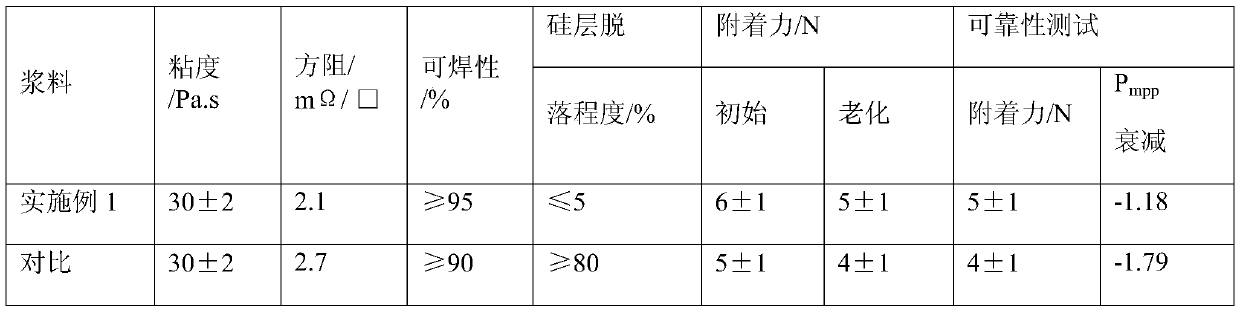

Embodiment 1

[0027] (1) Preparation of glass powder: Weighing: SiO 2 14.2 parts, Al 2 o 3 6.6 parts, TeO 2 17.0 parts, ZnO 28.8 parts, Bi 2 o 3 27.2 copies, WO 3 6.2 parts. After mixing the above materials evenly, preheat at 600°C for 15 minutes, melt at 1200°C for 1 hour, quench with deionized water and dry, then ball mill for 20 hours, and the average particle size is less than 5 microns after sieving and drying glass powder.

[0028] (2) Preparation of organic system: Weigh: 20.5 parts of ethyl cellulose, 7.5 parts of polyvinyl butyral, 30.3 parts of butyl carbitol acetate, 6.8 parts of dibutyl phthalate, diethylene glycol 12.7 parts of butyl ether acetate, 11.3 parts of tripropylene glycol monomethyl ether, and 10.9 parts of dodecyl alcohol ester. Disperse the above raw materials at a high speed and heat and dissolve at 80°C for 80 minutes. The specific time is subject to the clarity of the solution.

[0029] (3) Silver powder: the purity of flake silver powder is greater ...

Embodiment 2

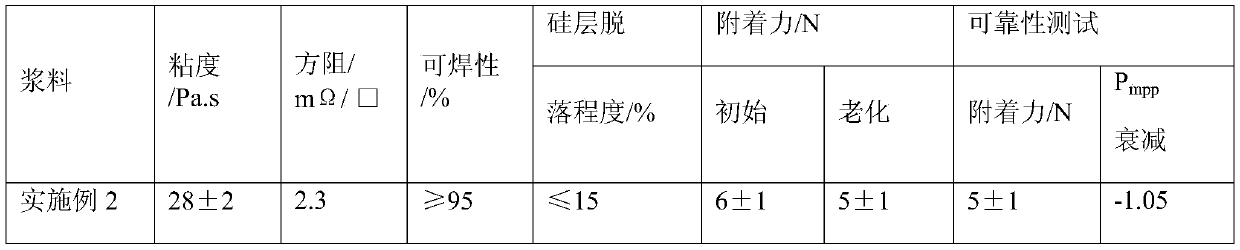

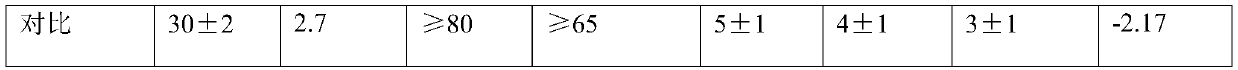

[0041] (1) Preparation of glass powder: Weighing: SiO 2 21.5 parts, Al 2 o 3 7.1 parts, TeO 2 12.2 parts, ZnO 22.5 parts, Bi 2 o 3 28.5 copies, WO 3 8.2 servings. After mixing the above materials evenly, preheat at 700°C for 18 minutes, then melt at 1250°C for 1 hour, quench with deionized water and dry, then ball mill for 22 hours, and the average particle size is less than 5 microns after sieving and drying glass powder.

[0042] (2) Preparation of organic system: weigh: 18.3 parts of ethyl cellulose, 5.6 parts of polyvinyl butyral, 28 parts of butyl carbitol acetate, 13.2 parts of dibutyl phthalate, diethylene glycol 11.3 parts of butyl ether acetate, 15.7 parts of tripropylene glycol monomethyl ether, and 7.9 parts of dodecyl alcohol ester. After dispersing the above raw materials at high speed, heat and dissolve at 100°C for 120 minutes. The specific time is subject to the clarity of the solution.

[0043] (3) Silver powder: the purity of flake silver powder ...

Embodiment 3

[0055] (1) Preparation of glass powder: Weighing: SiO 2 10 copies, Al 2 o 3 5 parts, TeO 2 25 parts, ZnO 40 parts, Bi 2 o 3 20 copies, WO 3 5 servings. After mixing the above materials evenly, preheat at 800°C for 20 minutes, then melt at 1300°C for 1 hour, quench with deionized water and dry, then ball mill for 24 hours, and the average particle size is less than 5 microns after sieving and drying glass powder.

[0056] (2) Preparation of organic system: Weighing: 15 parts of ethyl cellulose, 5 parts of polyvinyl butyral, 60 parts of butyl carbitol acetate, 15 parts of dibutyl phthalate, diethylene glycol 25 parts of butyl ether acetate, 20 parts of tripropylene glycol monomethyl ether, and 5 parts of dodecyl alcohol ester. Disperse the above raw materials at a high speed and heat and dissolve at 120°C for 240 minutes. The specific time is subject to the clarity of the solution.

[0057] (3) Silver powder: the purity of flake silver powder is greater than 99.90%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com