Purple sweet potato chip low-temperature drying equipment

A technology of low-temperature drying and purple potato chips, applied in application, food processing, food science and other directions, can solve the problems of increasing drying difficulty and cost, and achieve the effects of protecting and enhancing human health, avoiding contact and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The low-temperature drying equipment for purple potato slices of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. In the direction setting described in this patent, the motor installation side is the right side, and the oxygen removal device installation side is the left side. side.

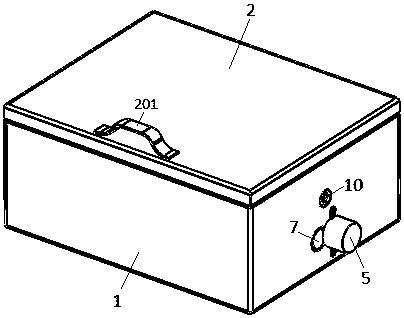

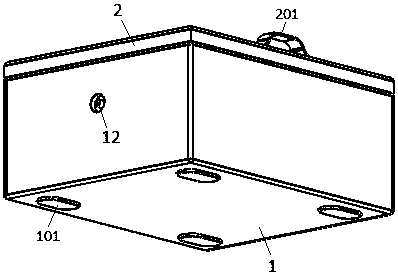

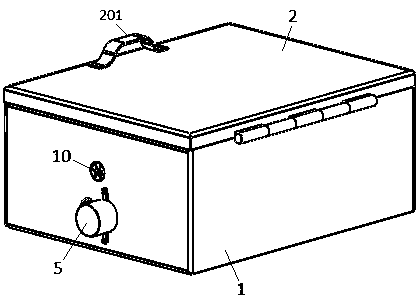

[0055] A low-temperature drying equipment for purple potato chips, characterized in that it includes a box body 1, a box cover 2, an inner tank 3, wheels 4, a motor 5, a driving wheel 6, a driven wheel 7, an internal gear 8, a rack 9, a pump Gas device 10, one-way valve 11, deoxygenation device 12; according to the function as a whole, it is divided into three parts: a holding part, a swing part and an air-drying part.

[0056] Such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the box cover 2 is hinged with the back side of the box body 1, the wheels 4 are installed at the bottom of the inner contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com