Automatic core taking mechanism and core taking method

An automatic, sand core technology, applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problem of the shape of the mud core requiring high sand box retreat space, etc., and achieve the effect of simple structure, simple operation and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

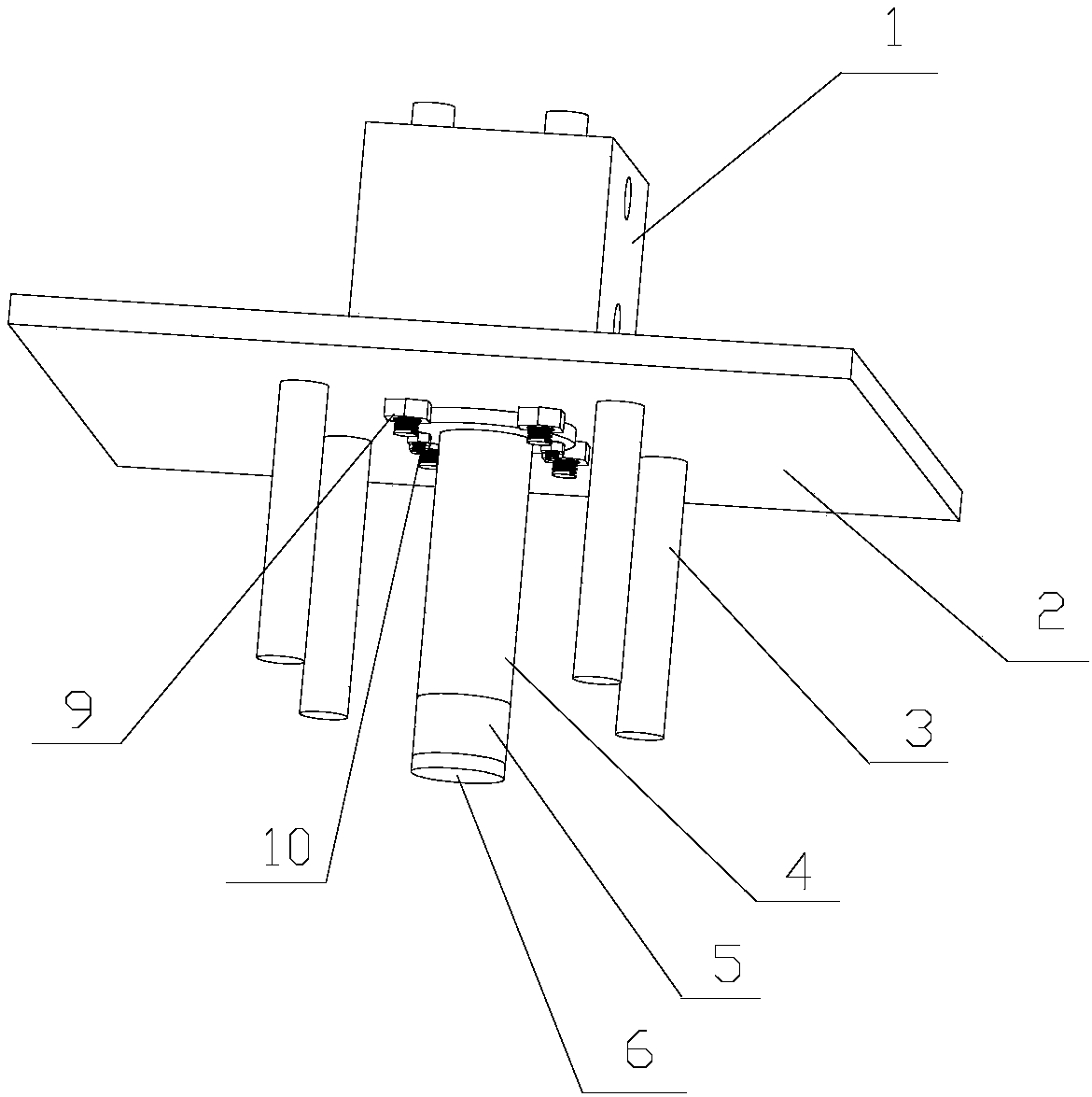

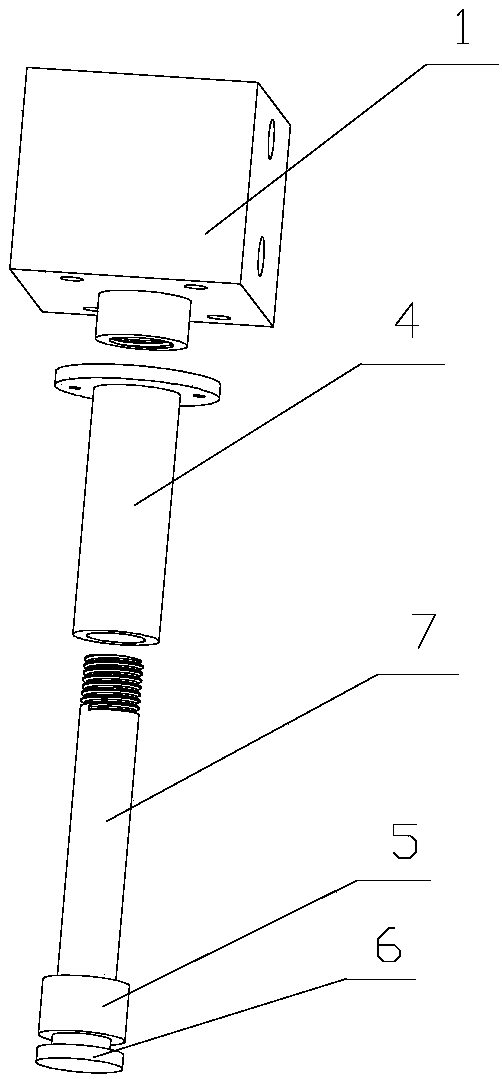

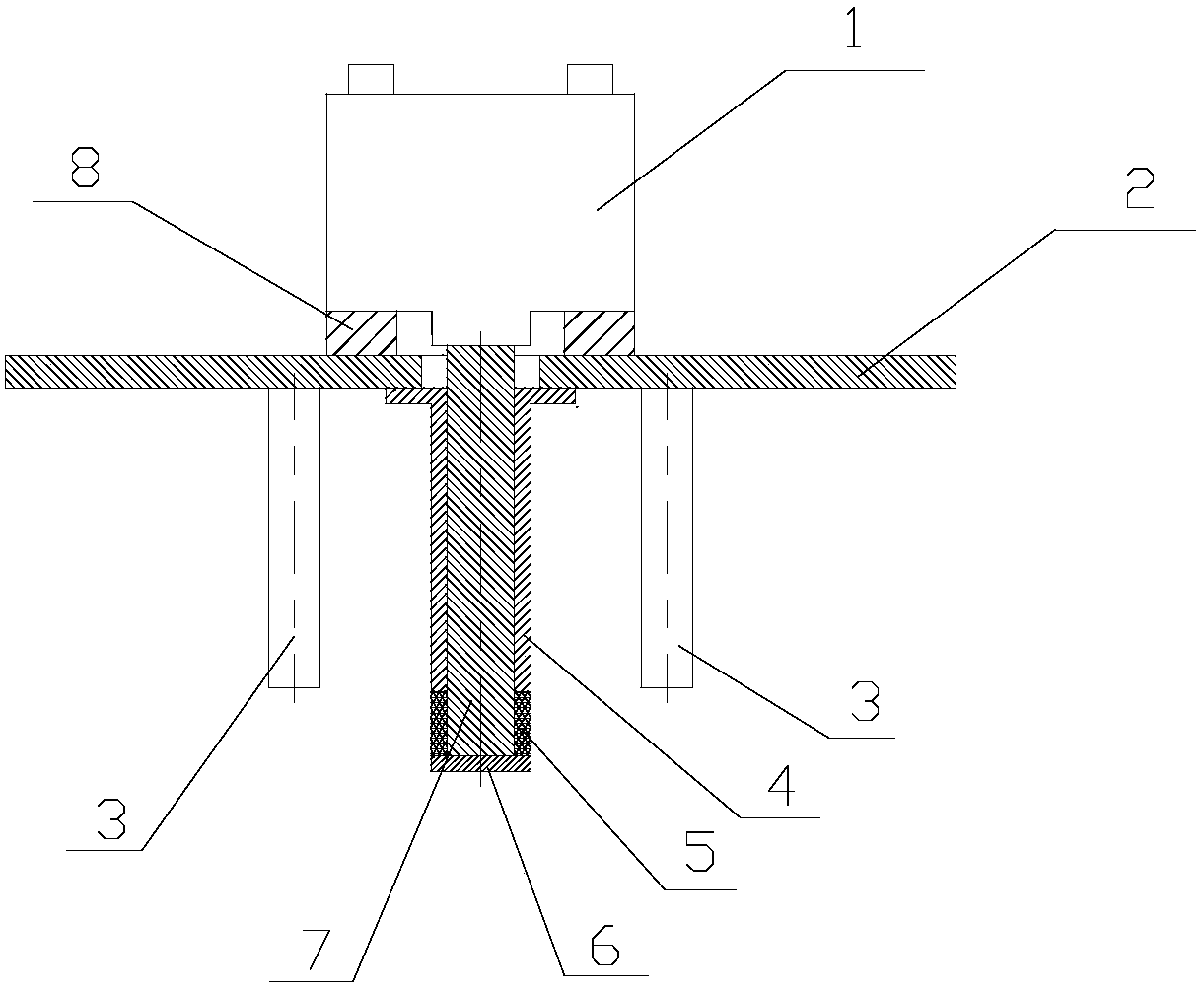

[0039] The automatic core lowering mechanism of the present embodiment has a structure such as figure 1 , figure 2 with image 3 As shown, it includes a cylinder 1, a fixed plate 2, a limit rod 3, a guide sleeve 4, a rubber sleeve 5, a limit block 6 and a guide rod 7. The upper end surface of the fixed plate 2 is provided with a cylinder 1, and the cylinder 1 acts as a driving guide. The effect of rod 7 moving up and down, between cylinder 1 and fixed plate 2, be provided with pad 8 that plays the role of supporting cylinder 1, pad 8 is provided with four screw holes 1, is provided with screw rod 1 9 with screw hole 1, cylinder 1 is installed on the fixed plate 2 through four screw rods 9 passing through the pad 8; the lower end surface of the fixed plate 2 is provided with a guide sleeve 4 and four limit rods 3, and the four limit rods 3 are evenly distributed around the guide sleeve 4 , and set vertically downward on the fixed plate 2, the limit rod 3 and the fixed plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com