Four-axis mechanical hand device applicable to high-temperature and high-dust environment and application thereof

A four-axis manipulator and manipulator technology, applied in the field of manipulators, can solve the problems of small activity radius restricting the layout of the assembly line, affecting the work efficiency of the manipulator, affecting the picking reliability, etc., and achieving the effect of reducing wasteful power consumption, simple structure, and large operating radius.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

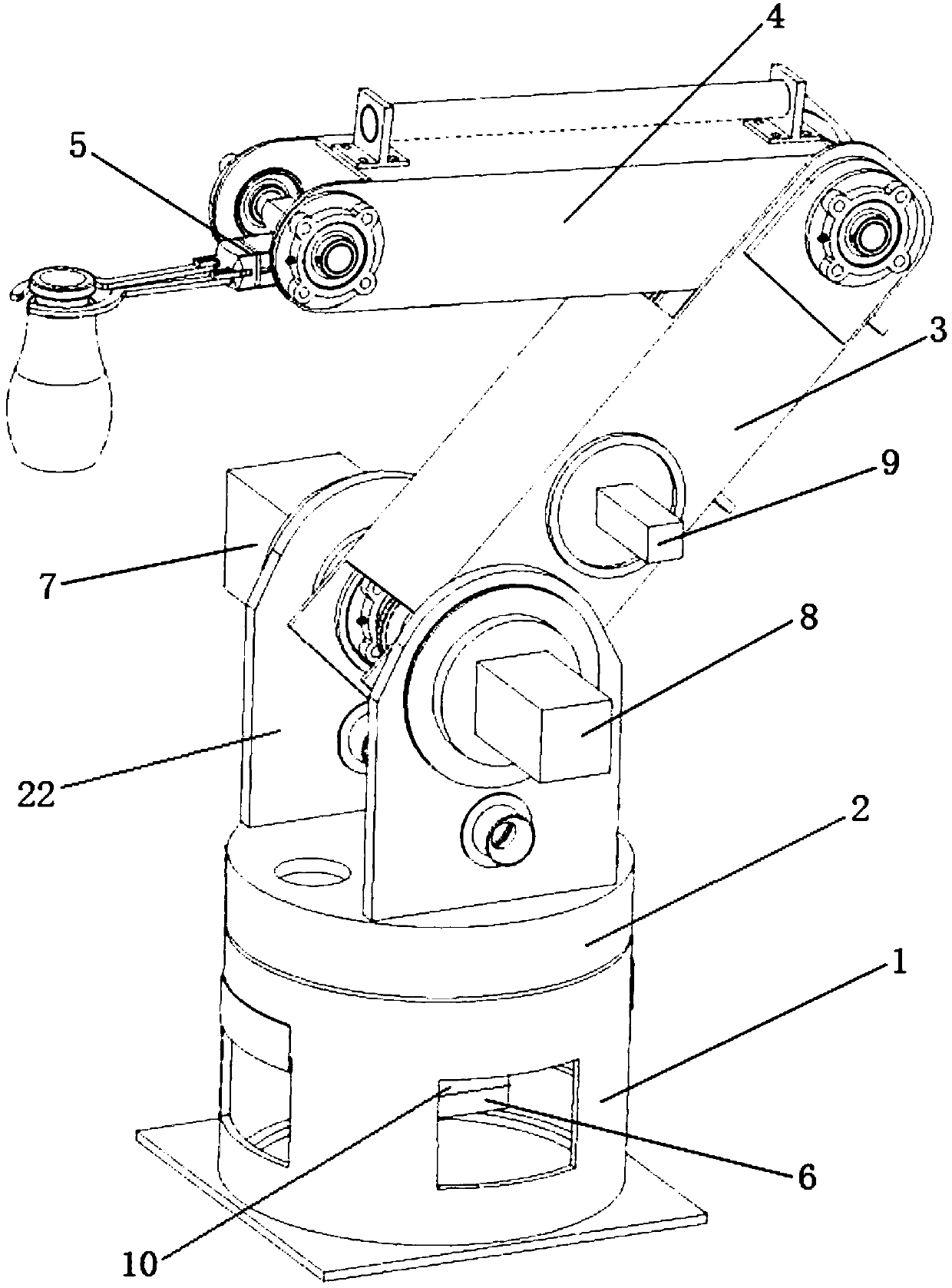

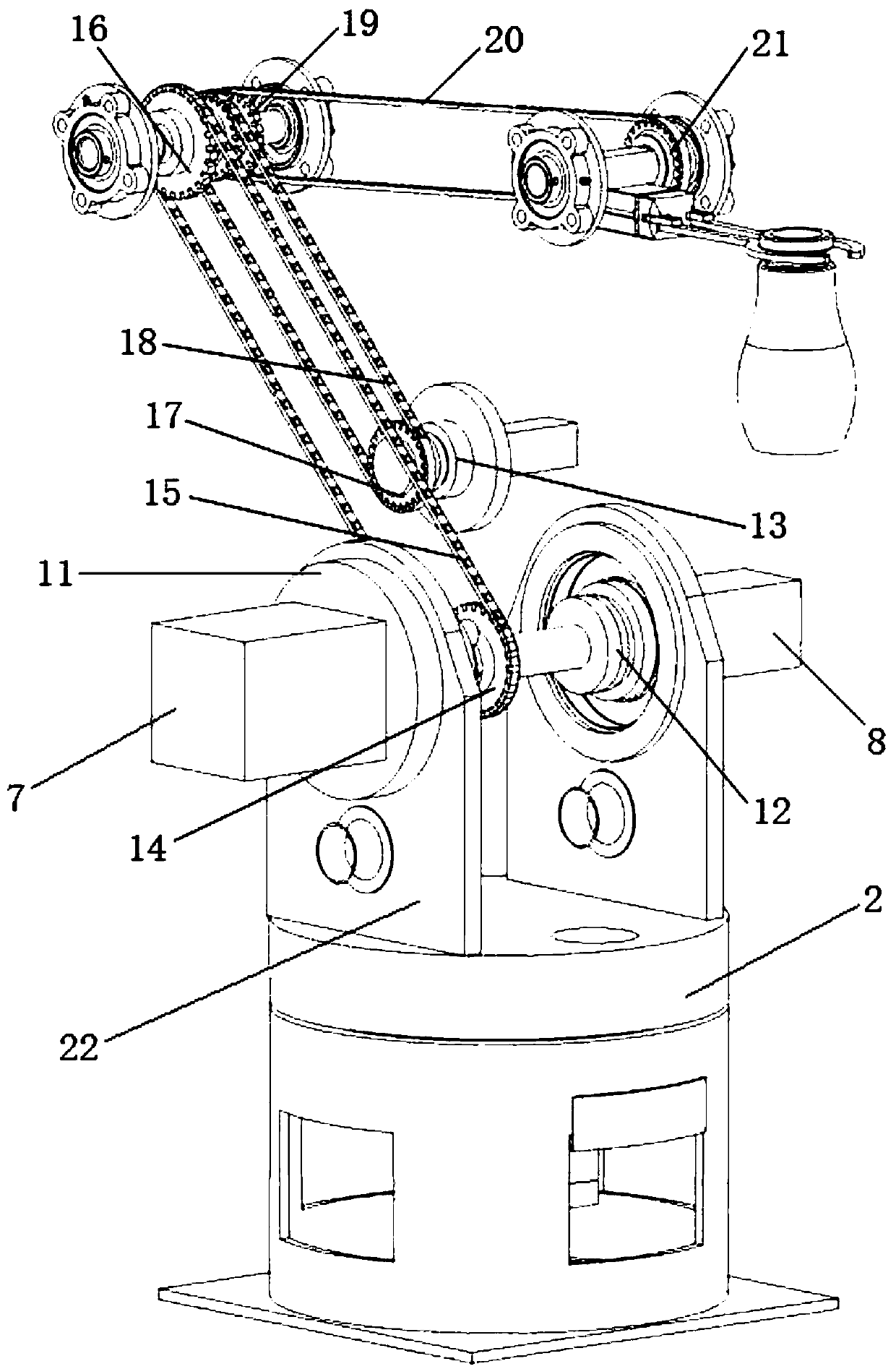

[0029] like figure 1 and figure 2 As shown, this embodiment provides a four-axis manipulator device suitable for high-temperature and high-dust environments, including a base 1, a revolving base 2, a large arm 3, a small arm 4, and a manipulator 5 arranged sequentially from bottom to top; the revolving base 2 is located at The base 1 is driven to rotate by the first motor 6 arranged on the base 1. The bottom of the boom 3 is connected to the swivel base 2 and driven to rotate by the second motor 7 arranged on the swivel base 2. The bottom of the small arm 4 is connected to the boom 3 is connected to the top and driven to rotate by the third motor 8 arranged on the slewing base 2, and the manipulator 5 is connected to the top of the forearm 4 and driven to rotate by the fourth motor 9 arranged on the big arm 3.

[0030] Wherein, the base 1 is a cylinder, the first motor 6 is installed in the inner cavity of the cylinder and connected with the first reducer 10 , the output sha...

Embodiment 4

[0035] The working principle of the four-axis manipulator device in this embodiment:

[0036] When the manipulator device is working, the manipulator grips and closes the glassware driven by the air source, adjusts the posture of the manipulator by controlling the rotation of each driving motor, moves the glassware to the designated position, releases the gripper by controlling the air source, and puts it down. glassware.

Embodiment 2

[0038] A working method of a four-axis manipulator device suitable for high-temperature and high-dust environments described in Embodiment 1, the specific working process is as follows:

[0039]During operation, by starting the first motor 6, the first motor 6 runs through the first reducer 10 to drive the revolving seat 2 to rotate on the base 1, which can realize the 360-degree rotation of the entire manipulator device; by starting the second motor 7, the second The motor 7 runs through the second reducer 11 to drive the boom to rotate around the first sprocket shaft; by starting the third motor 8, the third motor 8 runs through the third reducer 12 to drive the first sprocket shaft to rotate, and the first sprocket shaft is driven by the chain Drive the second sprocket shaft to rotate, while the second sprocket shaft rotates and drive the small arm 4 to rotate around the second sprocket shaft; by starting the fourth motor 9, the fourth motor 9 runs through the fourth reducer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com