Method for purifying lead liquid through dross removing agent

A technology of slag agent and lead liquid is applied in the field of using slag remover to purify lead liquid, which can solve the problems of unfavorable cost control, quality improvement, and high slag rate of lead-containing alloy products, so as to reduce labor intensity of workers and improve comprehensive performance. Recovery rate and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

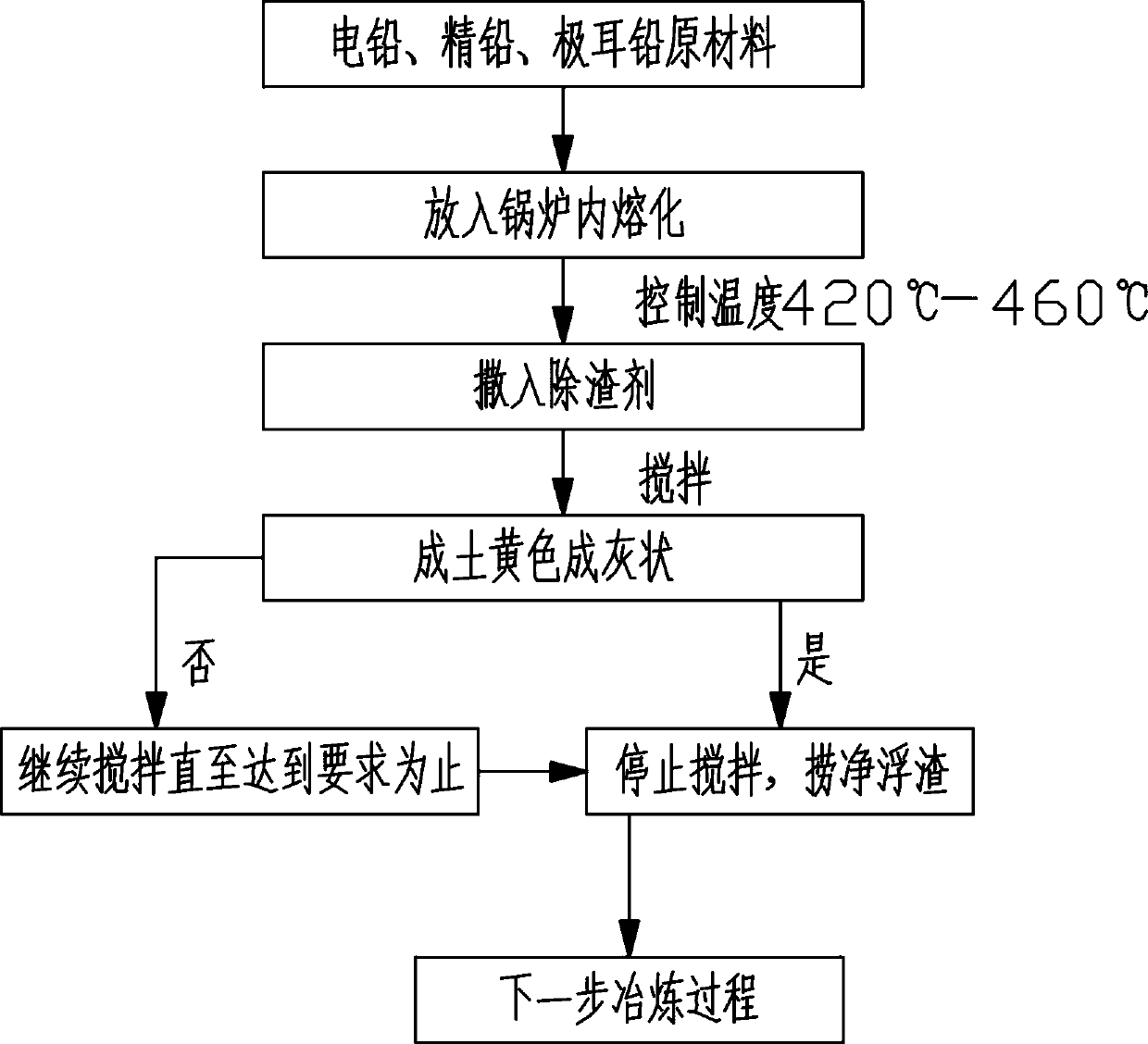

[0023] Embodiment 1: a kind of method that adopts slag remover to purify lead liquid, it is used for electric lead, refined lead and tab lead impurity removal, and it carries out according to the following steps:

[0024] Step 1: Put the raw materials of electric lead, refined lead or tab lead into the boiler, heat up to 420°C after melting;

[0025] Step 2: Weigh the slag remover according to the ratio of adding 0.6 kg of slag remover to 1 ton of lead;

[0026] Step 3: Sprinkle the slag removal agent weighed in Step 2 evenly on the surface of the melted lead liquid in Step 1, and keep the temperature stable at 420°C;

[0027] Step 4: Add the mixer to the boiler in step 3, start the mixer, and stir for 20 minutes;

[0028] Step 5: Observe the state of scum in step 4. If it is observed that the scum gradually disperses and changes from paste to gray, stop stirring when the scum turns to khaki, and pick up the gray scum. If the slag is not earthy yellow or ash-like, and the sl...

Embodiment 2

[0030] Embodiment 2: a kind of method that adopts slag removing agent to purify lead liquid, it is used for electric lead, refined lead and tab lead impurity removal, and it carries out according to the following steps:

[0031] Step 1: Put the raw materials of electric lead, refined lead or tab lead into the boiler, heat up to 460°C after melting;

[0032] Step 2: Weigh the slag remover according to the ratio of adding 0.8 kg of slag remover to 1 ton of lead;

[0033] Step 3: Sprinkle the slag removal agent weighed in Step 2 evenly on the surface of the melted lead liquid in Step 1, and keep the temperature stable at 460°C;

[0034] Step 4: Add the mixer to the boiler in step 3, start the mixer, and stir for 30 minutes;

[0035] Step 5: Observe the state of scum in step 4. If it is observed that the scum gradually disperses and changes from paste to gray, stop stirring when the scum turns to khaki, and pick up the gray scum. If the slag is not earthy yellow or ash-like, and...

Embodiment 3

[0037] Embodiment 3: a kind of method adopting slag removing agent to purify lead liquid, it is used for electric lead, refined lead and tab lead impurity removal, and it carries out according to the following steps:

[0038] Step 1: Put the raw materials of electric lead, refined lead or tab lead into the boiler, heat up to 440°C after melting;

[0039] Step 2: Weigh the slag remover according to the ratio of adding 0.7 kg of slag remover to 1 ton of lead;

[0040] Step 3: Sprinkle the slag removal agent weighed in Step 2 evenly on the surface of the melted lead liquid in Step 1, and keep the temperature stable at 440°C;

[0041] Step 4: Add the mixer to the boiler in step 3, start the mixer, and stir for 25 minutes;

[0042] Step 5: Observe the state of scum in step 4. If it is observed that the scum gradually disperses and changes from paste to gray, stop stirring when the scum turns to khaki, and pick up the gray scum. If the slag is not earthy yellow or ash-like, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com