Method for roasting hemimorphite and enriching zinc, lead and iron by utilizing pyrite

A technology for hemimorphite and pyrite, applied in the field of resources and environment, can solve the problems of large amount of leaching agent, many impurities, difficult recovery, etc., and achieves high lead-zinc sulfide conversion rate, high comprehensive recovery rate, and zinc-iron enrichment. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Magnetic Separation-Flotation Test of Sulfidation Roasting of a Hemimorphite in Lanping, Yunnan

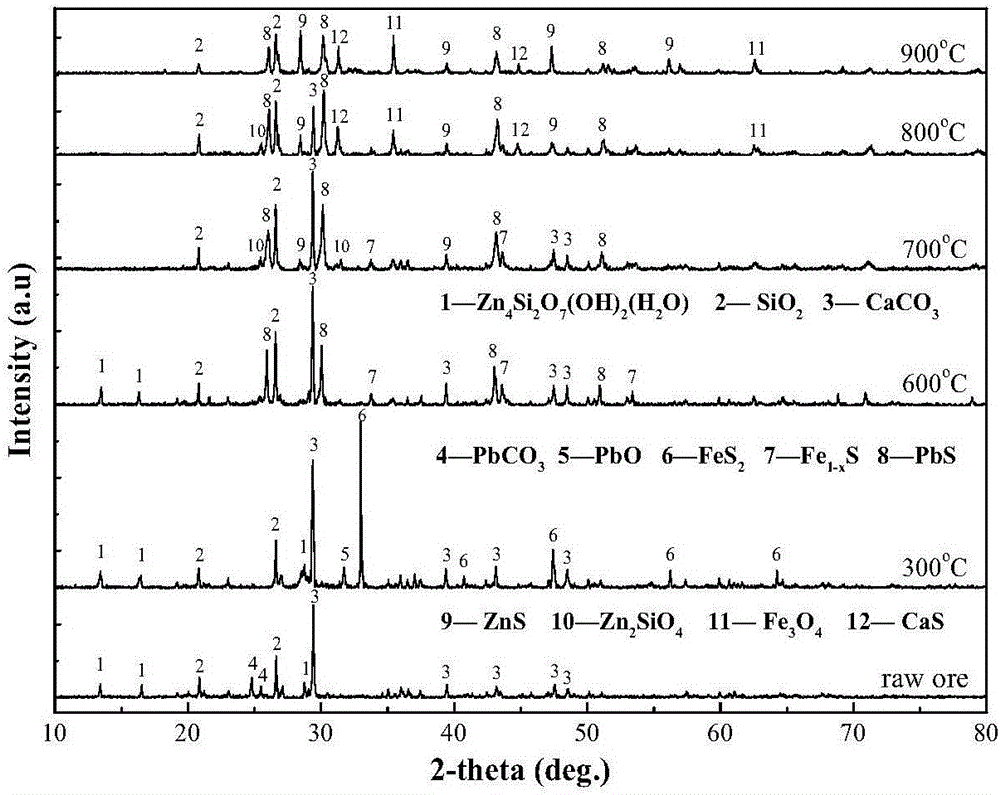

[0037] The main chemical composition of hemimorphite is: Zn 7.87%, Pb 6.94%, Fe 6.89%, Si 11.98%, Ca18.43%, of which Zn and Pb are mainly composed of Zn 4 Si 2 o 7 (OH) 2 h 2 O, PbCO 3 form exists. The experimental results show that the process is also effective for PbCO 3 It has better vulcanization effect.

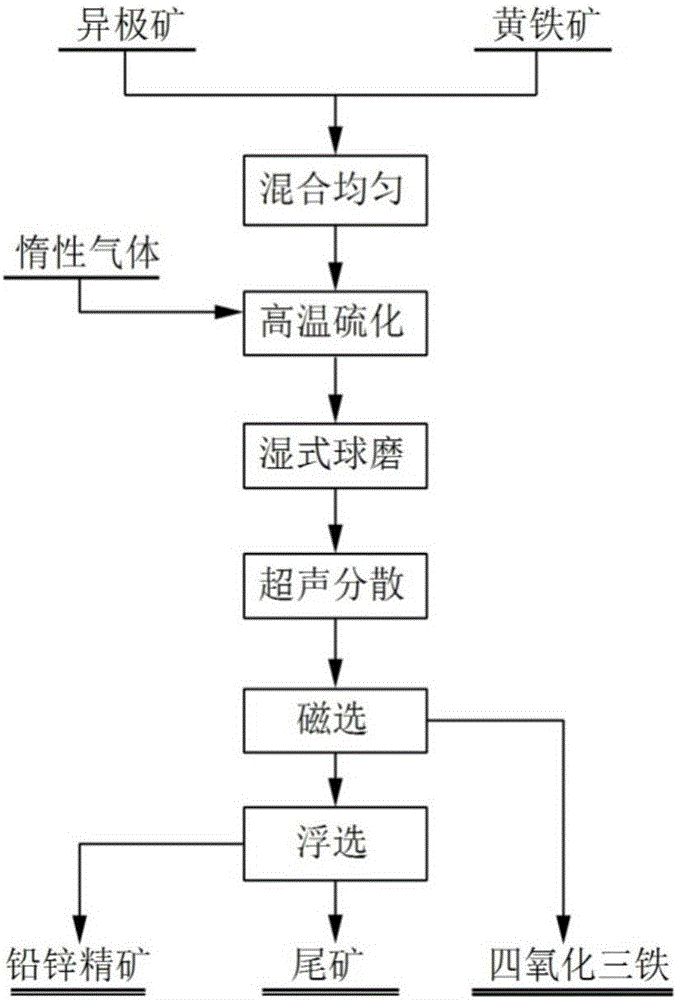

[0038] (1) According to figure 1 According to the advanced technological process, the hemimorphite and pyrite are ground according to the mass ratio of 4:1, mixed evenly, and roasted at 900-950°C for 20-30min under the protection of nitrogen. The measured lead-zinc vulcanization rate is as high as 92% and 98%. %above. For XRD analysis of hemimorphite raw ore and sulfidation roasting products, see figure 2 .

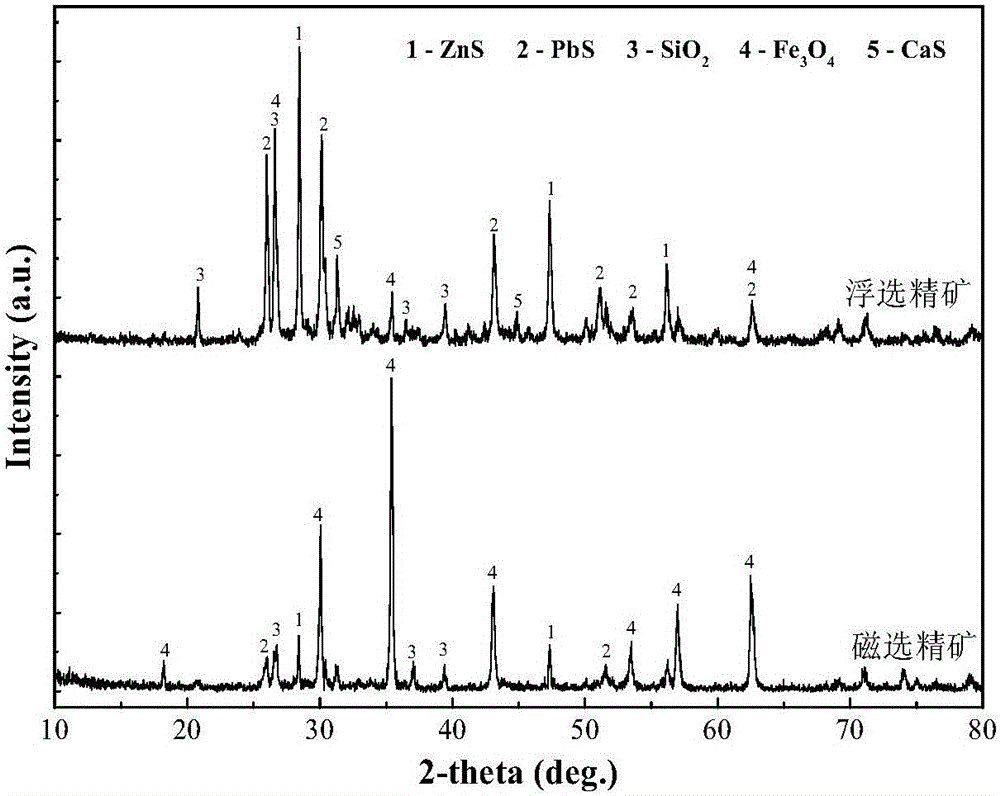

[0039] (2) The vulcanization and roasting product is wet ball milled with water for 60-120 minutes, then ultrasonically dispersed for 20-3...

Embodiment 2

[0041] Example 2: Sulfidation Roasting Magnetic Separation-Flotation Test of a Hemimorphite in Guangxi

[0042] The chemical composition of hemimorphite is: Zn 16.23%, Fe4.64%, Pb 0.79%, Si 18.58%, Ca7.25%, among which zinc is mainly zinc silicate (Zn 2 SiO 4 ) and zinc silicate hydrate (Zn 4 Si 2 o 7 (OH) 2 h 2 O) exists.

[0043] (1) According to figure 1 According to the advanced technological process, the hemimorphite and pyrite are ground according to the mass ratio of 10:3 and mixed evenly. The temperature is controlled at 750-850°C, and the roasting time is 20-40min. The measured zinc vulcanization rate is as high as 95%. .

[0044] (2) Grind the vulcanized product first, add water and ultrasonically disperse it for 20-30 minutes, then adjust the liquid-solid ratio to 20:1, fully stir it into a slurry, and then directly perform magnetic separation. The magnetic field strength of the magnetic separation is 0.10-0.12T. Choose a time of 15 to 20 minutes. The measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com