Continuous production equipment for lithium manganese battery cathode material

A lithium manganate battery and production equipment technology, applied in battery electrodes, lighting and heating equipment, manganate/permanganate, etc., can solve the problems of high cost and long preparation time, and achieve energy saving and simple structure , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

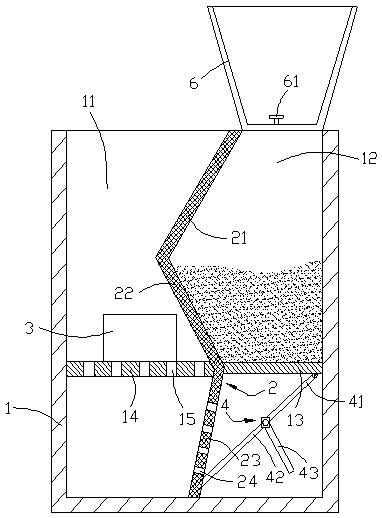

[0013] Combine below figure 1 The present invention is described in detail, and the illustrative embodiments and description of the present invention are used to explain the present invention, but are not intended to limit the present invention.

[0014] The continuous production equipment of lithium manganate battery cathode material includes a baking chamber 1, which is divided into two spaces on the left and right by a heat conducting plate 2, one of which is the heating chamber 11, and the other is for holding lithium manganate gel In the containing chamber 12, the heating chamber transfers heat to the containing chamber to dry and roast the lithium manganate gel. It can be seen that the present invention uses one roasting chamber to realize the storage, drying and roasting of the lithium manganate gel , Its structure is simple and cost is low. At the same time, the container 6 is heated through the preheating of the containing chamber, which not only makes full use of waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com