Drying system of shoe-making production line

A drying system and production line technology, which is applied in the field of drying systems, can solve the problems of large power consumption and achieve the effects of energy saving, convenient operation and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

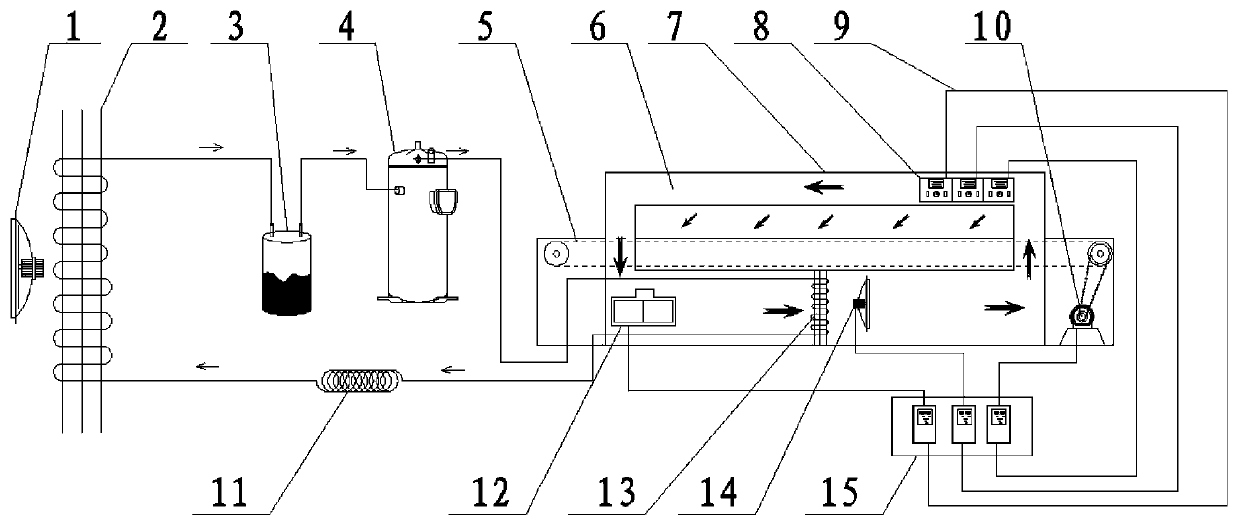

[0020] Such as figure 1 As shown, the drying system of the shoe-making production line of the present invention includes a conveyor belt 5 and a drying box 7 for conveying shoes, the conveyor belt 5 is driven by a drive motor 10, and the conveyor belt 5 passes through both sides of the drying box 7. The drying system also includes an air source heat pump device. Specifically, the evaporator 2 is sequentially connected to the gas-liquid separator 3, the compressor 4, the condenser 13, and the throttling device 11 through a refrigerant pipeline. 11 is finally connected to the evaporator 2 through the refrigerant pipe. The condenser fan 14 is installed at the end of the condenser 13, and the condenser 13 and the condenser fan 14 are installed in the drying box 7, and the condenser fan 14 allows the condenser 13 to circulate and heat the air in the drying box 7.

[0021] In order to allow the hot air to dry the shoes on the conveyor belt 5 better, the inner wall of the drying box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com