Filter component for cleaning machine

A filter assembly and cleaning machine technology, applied in the direction of mobile filter element filter, filter separation, separation method, etc., can solve the problems of increasing enterprise cost, poor filtering effect, complex structure, etc., to reduce cleaning cost, reduce waste, increase The effect of high dirt load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

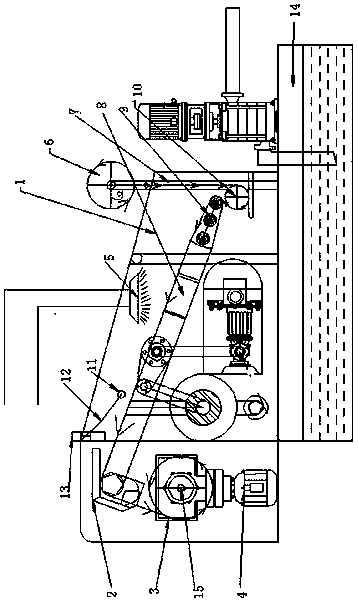

[0012] Embodiment 1: see figure 1 , a filter assembly for a cleaning machine, the filter component includes a filter cloth scraper 2, a dirty cloth drum 4, a drum motor 4, a nozzle 5, a clean cloth drum 6, a partition bracket 7, a hollow partition 8, an auxiliary filter cloth Drum 9, drum shaft 15 and cylindrical interception column 10; the filter cloth scraper is installed above the dirty cloth drum; the drum motor is connected to the dirty cloth drum; the nozzle is installed above the hollow partition; the clean cloth The roller is installed above the partition bracket; the upper and lower ends of the hollow partition are respectively connected with the filter cloth auxiliary drum and the filter cloth scraper; the cylindrical intercepting column is installed under the partition bracket, and the hollow partition, cylindrical The closed space formed by the interception column, the filter cloth auxiliary drum and the partition bracket forms a dirty liquid chamber. When the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com