Carbon fiber plate material and manufacturing method thereof

A carbon fiber sheet, carbon fiber cloth technology, applied in chemical instruments and methods, other household appliances, lamination and other directions, can solve the problems of affecting the appearance, broken lines, damage to the unidirectional carbon fiber cloth lines, etc., to solve the problem of surface cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

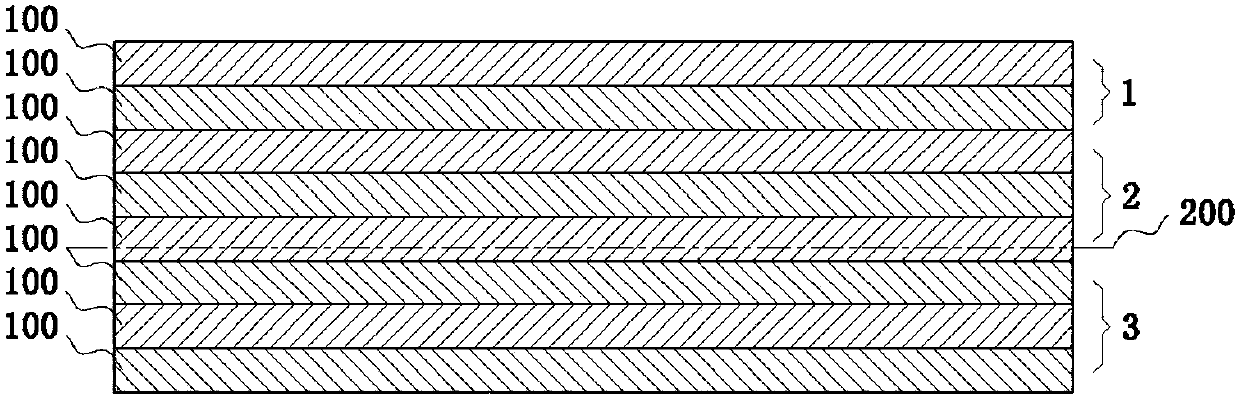

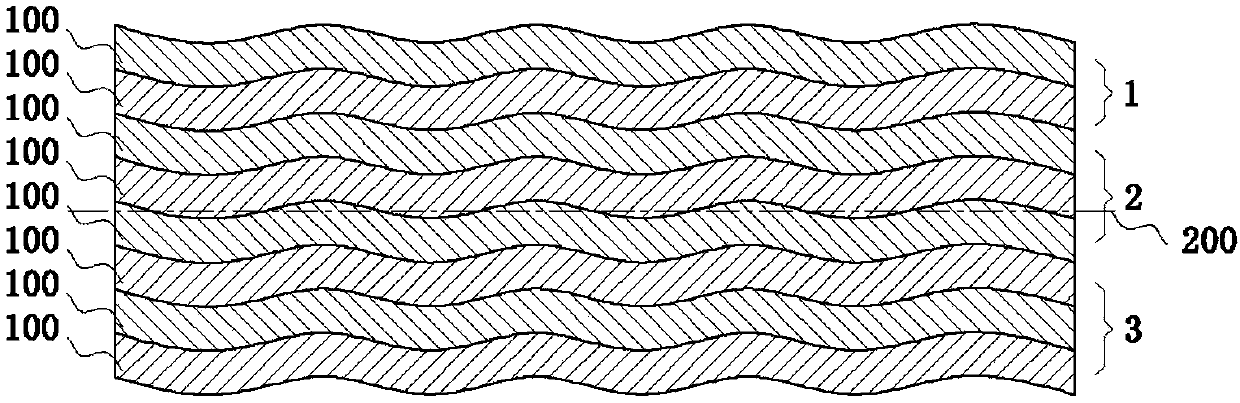

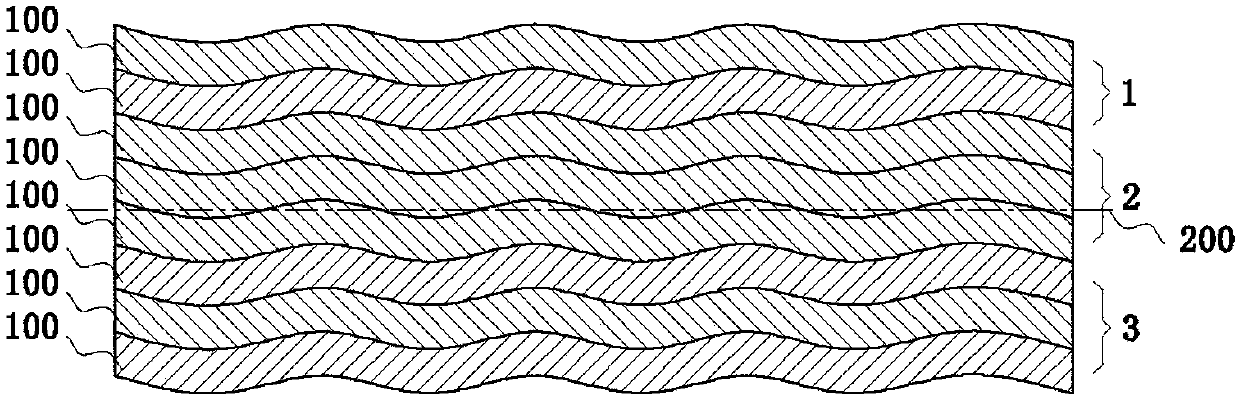

[0021] as attached image 3 As shown, a carbon fiber plate is formed by a number of (8 layers shown in the figure) unidirectional carbon fiber cloth 100 impregnated with resin and then laminated and solidified. From the bottom down, it is divided into upper layer group 1 (a total of 2 layers shown in the figure), middle layer group 2 (a total of 3 layers shown in the figure) and lower layer group 3 (a total of 3 layers shown in the figure), and each carbon fiber that constitutes the middle layer group 2 Cloth 100 has at least two layers.

[0022] The carbon fiber cloths 100 constituting the upper group 1 are stacked in opposite directions with the carbon fiber filaments of the adjacent carbon fiber cloths 100, the carbon fiber fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com