Longitudinal roller and transverse disk type rare earth magnetic disk separation device for arc shell bottom plate

A rare earth magnetic disk and separation device technology, applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve problems such as easy sedimentation, and achieve the effect of large adsorption capacity and prolonged effective time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution will be described in detail below in conjunction with the accompanying drawings and specific embodiments

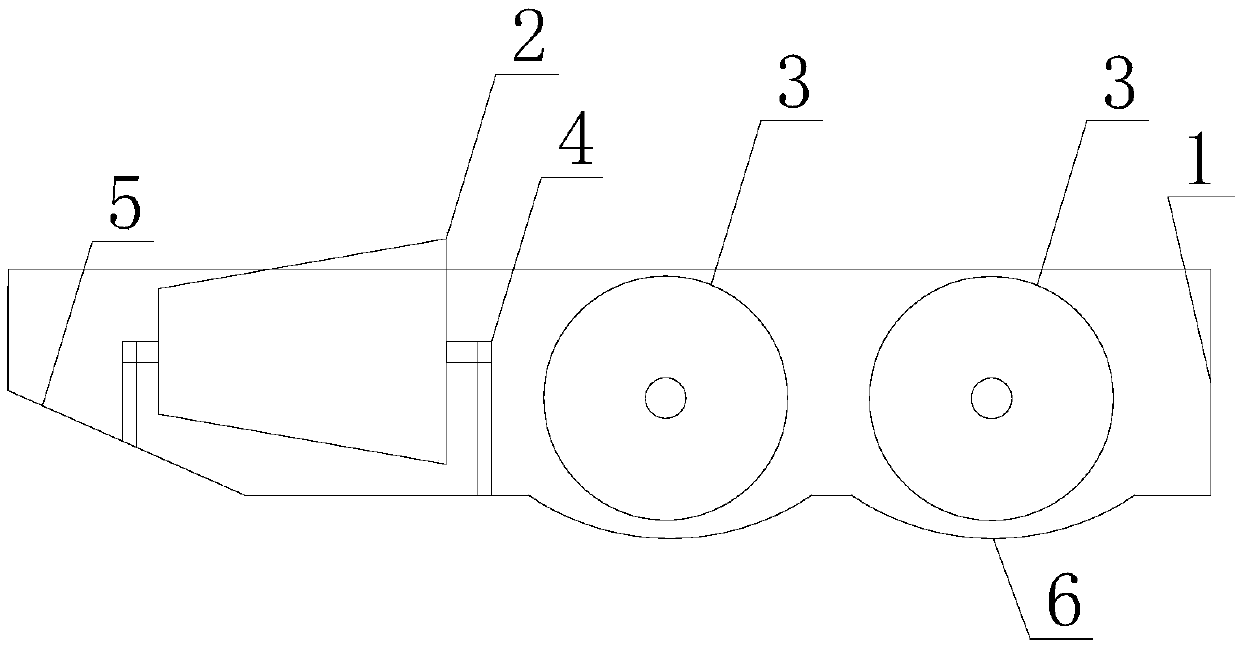

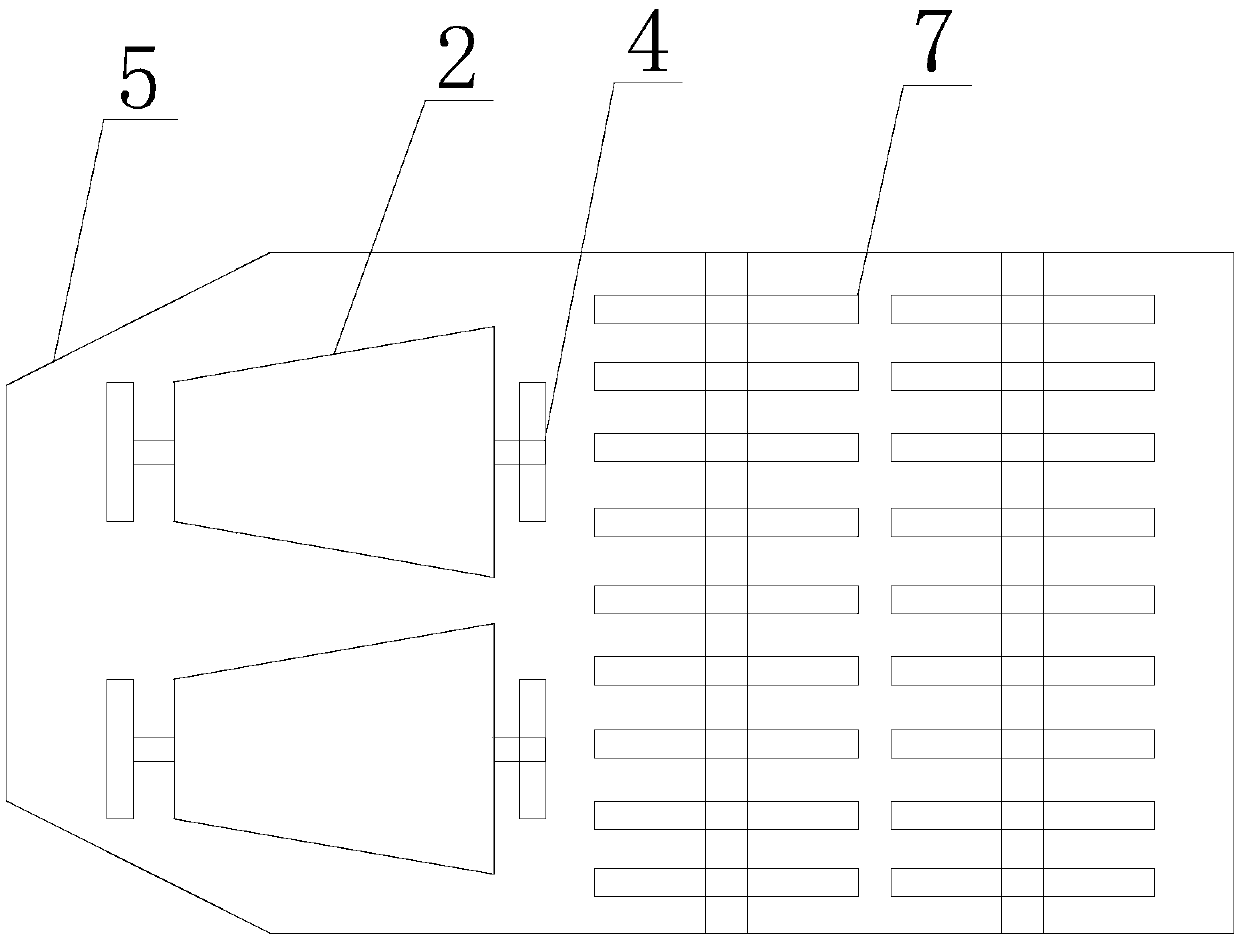

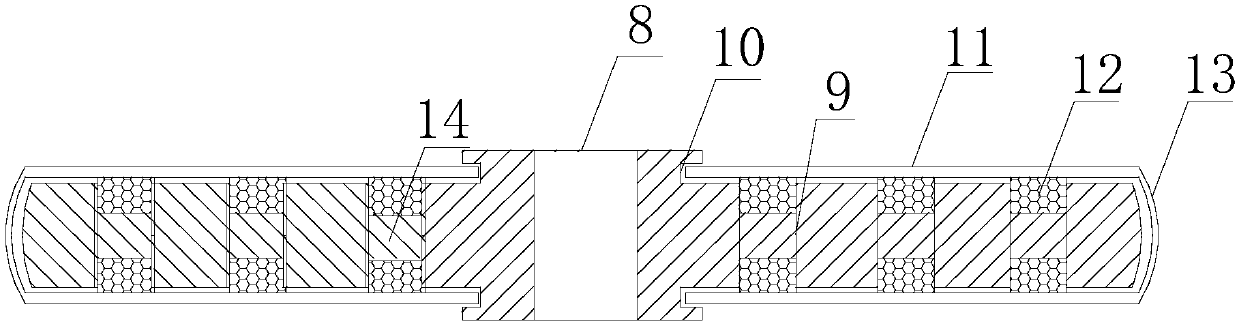

[0015] As shown in the figure, a rare earth disk separation device with a longitudinal roller and horizontal disk type arc shell bottom plate includes a longitudinal magnetic roller 2 and a transverse disk group 3, and the longitudinal magnetic roller 2 and the transverse disk group 3 are vertically installed in the adsorption pool 1 In it, the longitudinal magnetic roller 2 is installed on the fixed frame 4, and the transverse disk group 3 is installed on the side wall of the adsorption pool 1. The longitudinal magnetic roller 2 is a tapered structure and arranged parallel to the water flow direction; the transverse disk group 3 It consists of a number of disks 7, the disk 7 includes a disk body 8, a number of installation through holes 9 are arranged on the disk body 8, an intermediate body 14 is placed in the middle of the installation thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com