Crawler paver with preheating function and method thereof

A pre-heating, crawler-type technology, applied in the field of construction machinery, can solve the problem of formation of faults in asphalt mixture, and achieve the effect of reducing faults, reducing road surface diseases and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

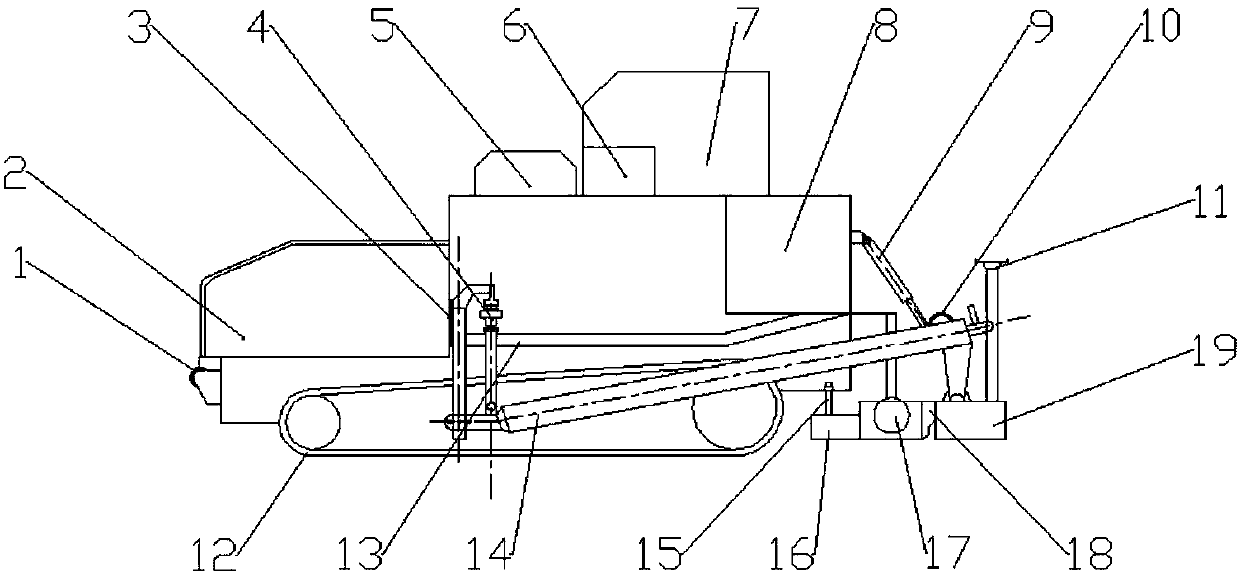

[0027] The present invention is further described below in conjunction with accompanying drawing:

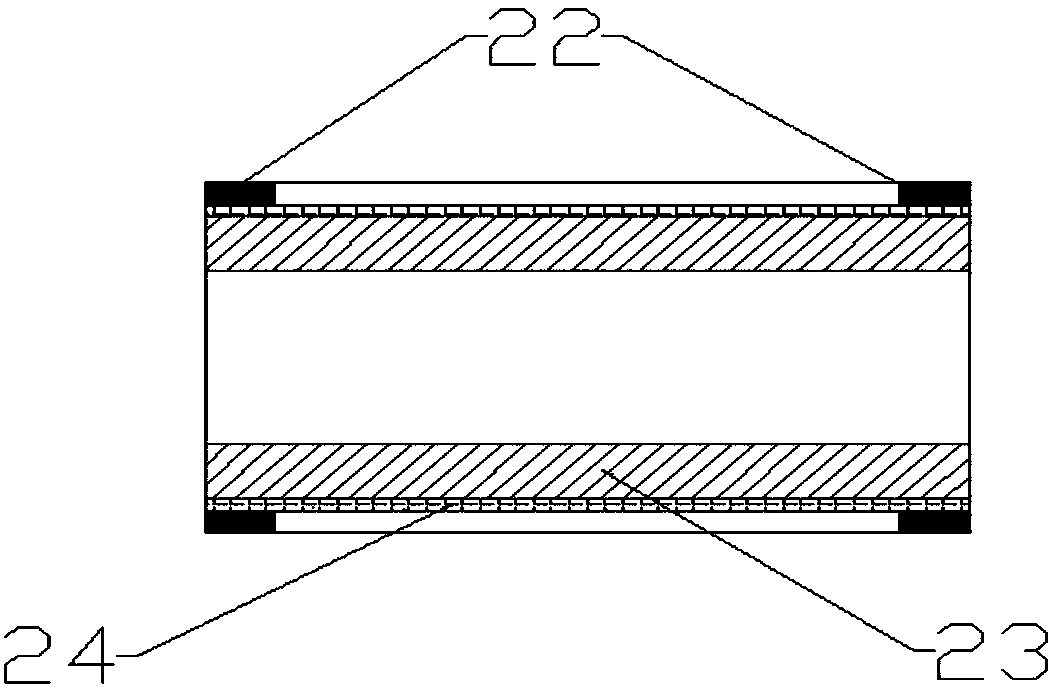

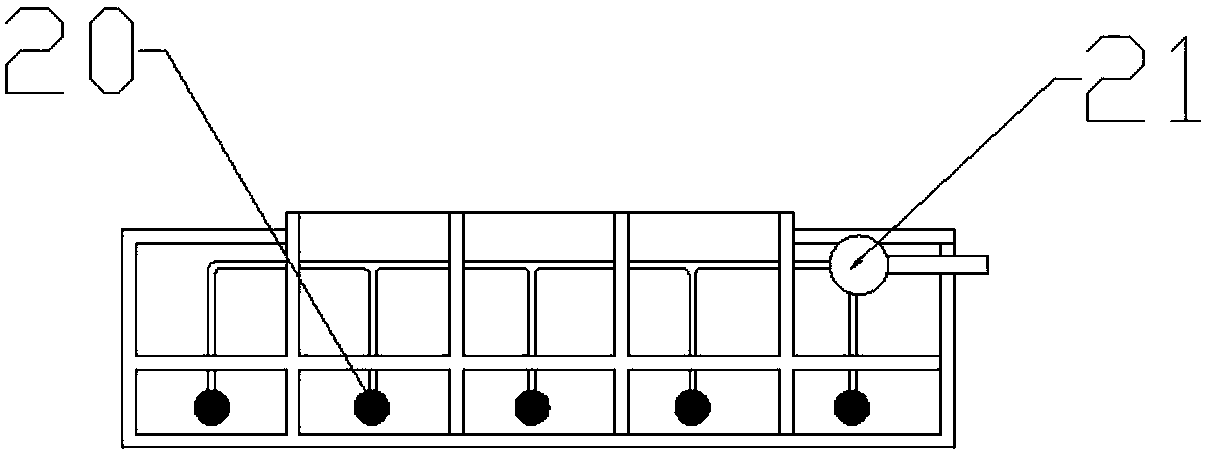

[0028] see Figure 1-Figure 3 , a crawler paver with preheating function, including an adjustment mechanism, a material delivery mechanism, a car body, a generator 8 and an infrared heater 16; the material delivery mechanism, the infrared heater 16, the generator 8 and the adjustment mechanism are all It is arranged on the car body; the transport mechanism includes a scraper conveyor 13, a screw distributor 17, a vibrator 18 and a screed 19; the scraper conveyor 13 is arranged on the car body, and the scraper conveyor 13, the screw distributor 17. The vibrator 18 and the screed 19 are connected in sequence; the screed 19 is provided with a heating system 21 for heating the screed 19, and the infrared heater 16 is arranged on one side of the screw distributor 17; the infrared heater 16 includes a hollow Ceramic tube 23, electrothermal infrared radiation coating 24 and electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com