Fabricated concrete structure and construction method

A concrete structure and prefabricated technology, which is applied in the direction of building construction and construction, to achieve the effects of good impact resistance and pressure resistance, precise factory production, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

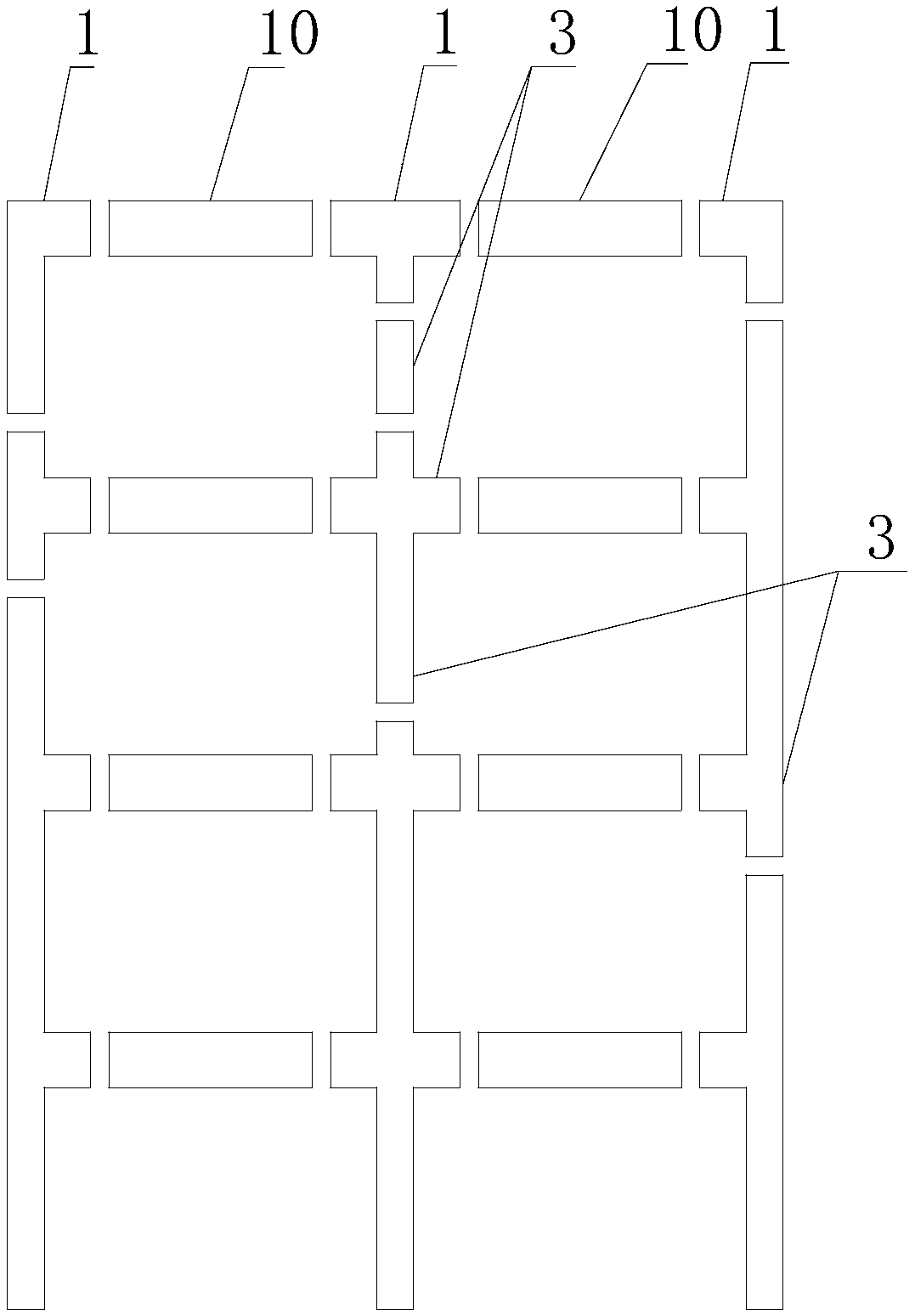

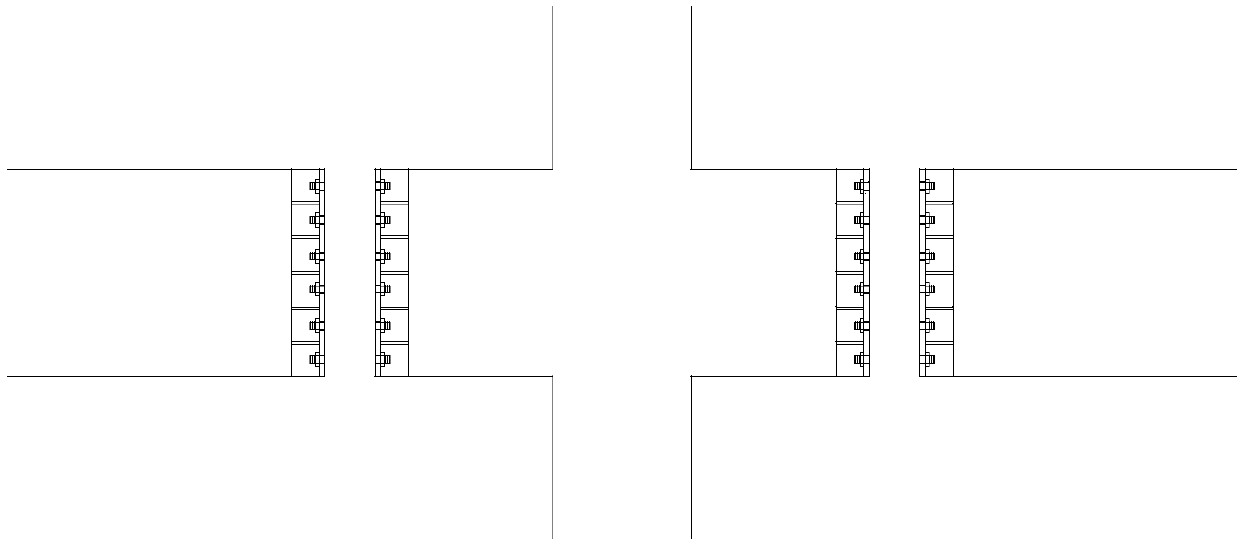

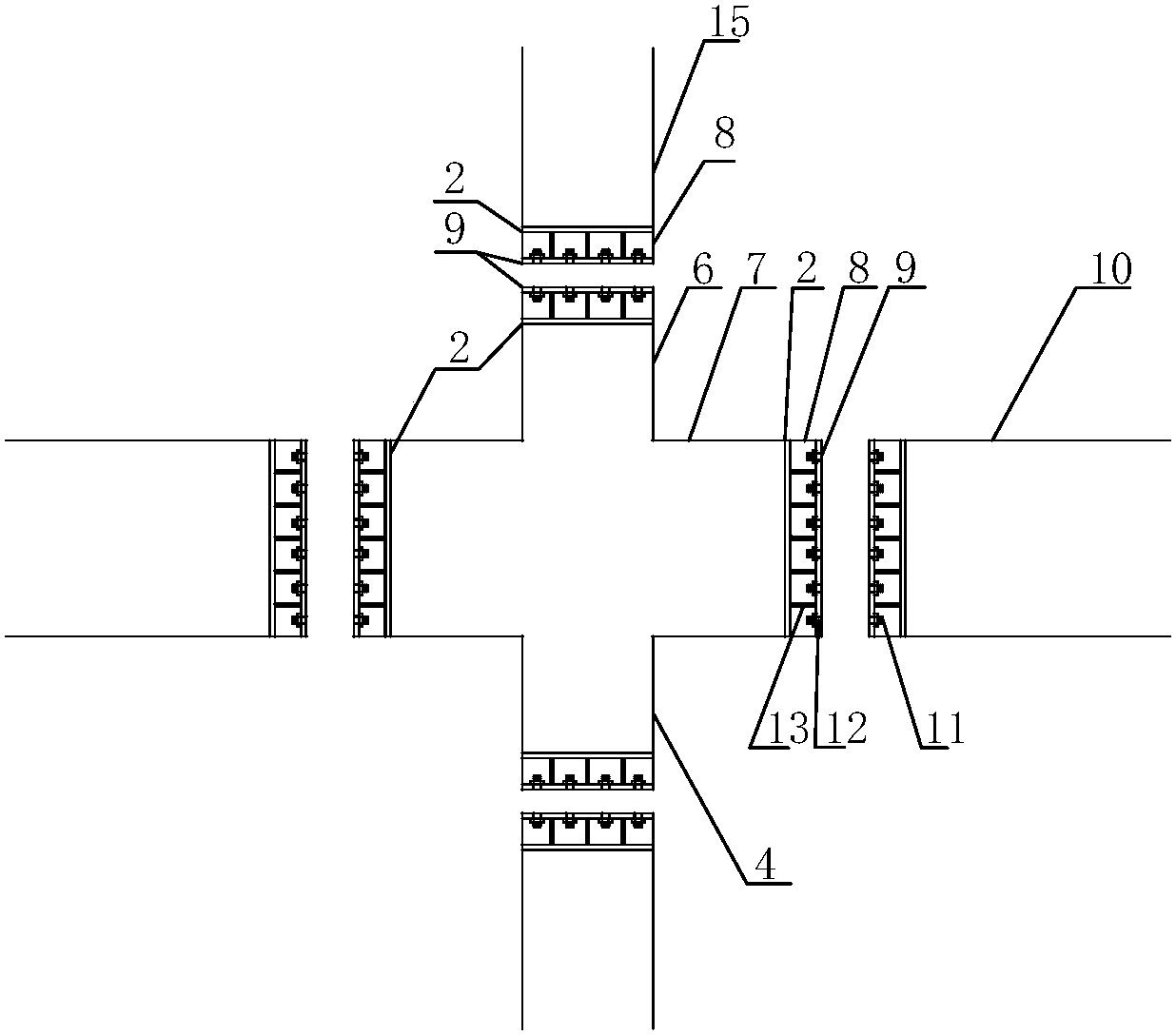

[0038] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 The prefabricated concrete structure shown in , is used for building buildings with a concrete frame structure, and the concrete frame is formed by splicing prefabricated beam-column sections including prefabricated connecting beams 10 and prefabricated column sections 6 . figure 1 It is a schematic diagram of a partial elevation, wherein the column 15 is spliced by a plurality of prefabricated column sections 6, and the prefabricated column sections 6 are designed with different lengths according to requirements. The prefabricated column section 6 is provided with an overhang beam 7 horizontally at the installation position of the connecting beam, and the vertically adjacent prefabricated column sections 6, and between the prefabricated column section 6 and the horizontally adjacent connecting beam 10 are all connected by bolts 8 Connection, thus cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com