Method for correcting core oil saturation by using well logging resultant curve

A technology of logging curves and saturation, applied in the direction of extracting undisturbed core devices, earthwork drilling, wellbore/well components, etc., can solve problems such as core expansion cracks, overburden pressure reduction, core pore expansion cracks, etc., to achieve technical ideas Clear, conducive to promotion, good operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

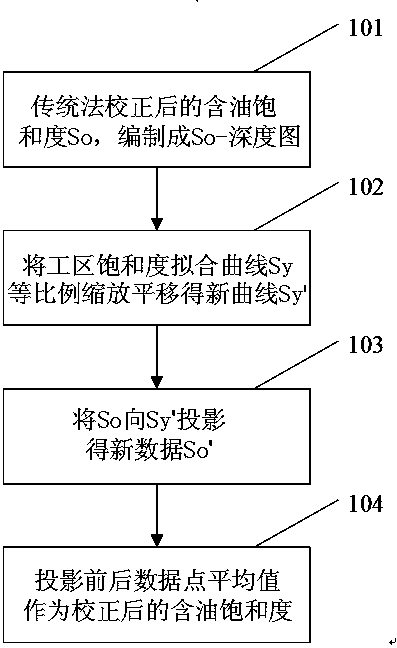

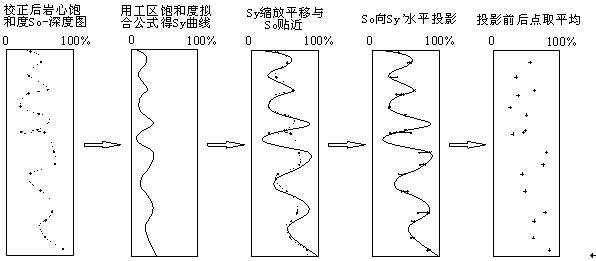

[0022] Such as figure 1 with figure 2 as shown, figure 1 with figure 2 It is a flow chart and a flow chart of the method for correcting core oil saturation with logging synthetic curves of the present invention.

[0023] In step 101, the weighted average correction method is used to correct the core oil saturation data So, and compile a So-depth map. The process goes to step 102.

[0024] Step 102, according to the porosity of a work area Oil saturation fitting formula

[0025]

[0026]

[0027] The newly synthesized logging curve Sy is obtained from two logging curves of acoustic transit time AC and induction resistivity COND:

[0028] Sy=100-100*10 0.54952*log(0.005512AC–0.283)-0.63547*log(1000 / cond)+0.5116

[0029] Scale and transl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com