Integrated immersed pipe section, installing method thereof and installing and closure method of immersed pipe section

An installation method and technology of pipe joints, applied in the direction of pipes/pipe joints/pipes, shaft equipment, earth-moving drilling, etc., can solve the problems of uneven settlement, endangering submarine tunnels, etc. The effect of engineering risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

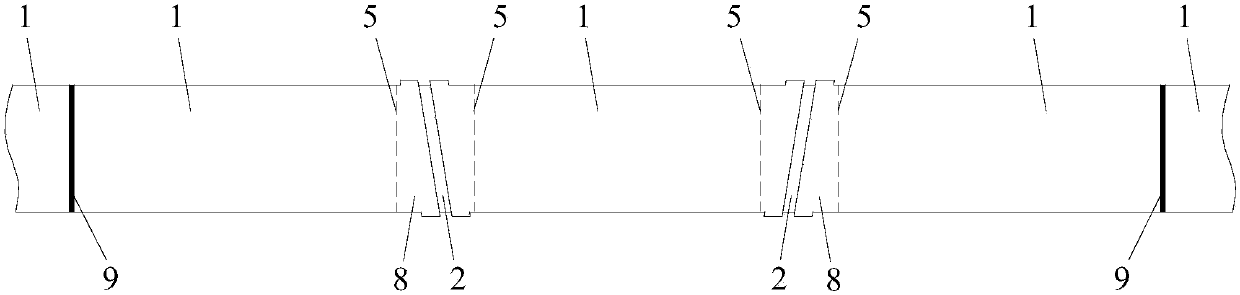

[0095] Such as figure 1 , 4 As shown in -6, an integrated immersed tube joint according to the present invention includes a standard immersed tube joint 1, and both ends of the standard immersed tube joint 1 are provided with closed ring-shaped retractable water-stop joints 2.

[0096] Both ends of each immersed tube section are respectively provided with end seal doors 5 to prevent seawater from entering the inside of the immersed tube section. After the immersed tube section is docked with the installed immersed tube section, two adjacent A junction cavity 8 is formed between two end seal doors 5 opposite to each immersed tube section, wherein as Figure 1-3 As shown, the other ordinary immersed tube joints at the non-final closing place are connected through sinking butt joints 9, and after the water in the joint cavity 8 is discharged, the end seal door 5 is removed so that two adjacent The immersed tube section is connected, and the immersed tube section here includes ...

Embodiment 2

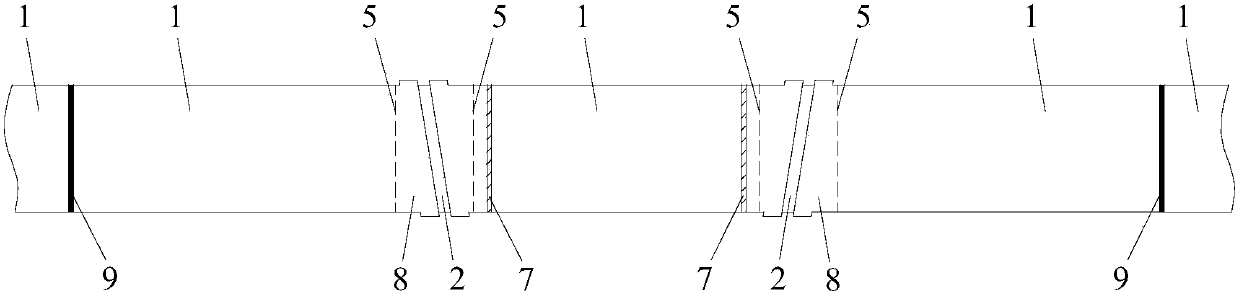

[0104] As shown in Figure 2, an integrated immersed tube joint according to the present invention includes a standard immersed tube joint 1, and both ends of the standard immersed tube joint 1 are provided with closed ring-shaped retractable water stop Connector 2.

[0105] The difference from Example 1 is that the standard immersed tube section 1 included in the integrated immersed tube section is provided with two flexible joints 7, and each of the flexible joints 7 makes the standard immersed tube section 1 It is flexible while maintaining rigidity, which facilitates the release of internal stress of the standard immersed tube section 1 after closing.

[0106] As a preferred solution of this embodiment, the standard immersed tube section 1 is provided with two flexible joints 7 near both ends, and the two flexible joints 7 divide the standard immersed tube section 1 into three sections Tube segment. Each of the flexible joints 7 includes a closed ring-shaped first waterst...

Embodiment 3

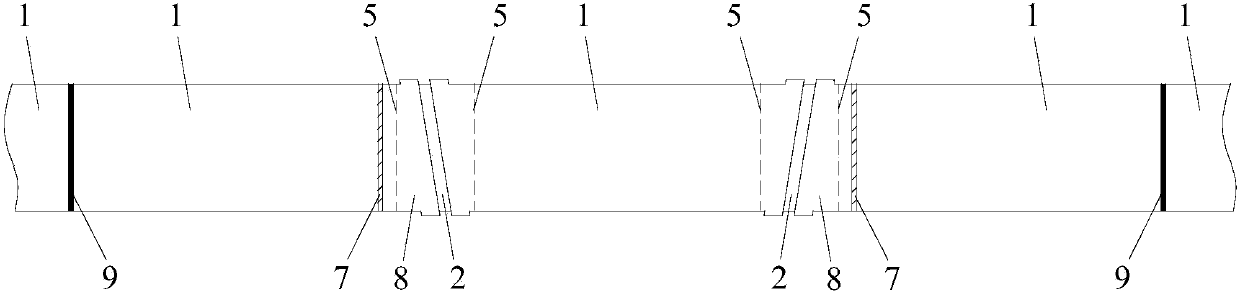

[0109] As shown in Figure 3, an integrated immersed tube joint according to the present invention includes a standard immersed tube joint 1, and both ends of the standard immersed tube joint 1 are provided with closed ring-shaped retractable water stop Connector 2.

[0110] The difference from Example 1 is that the standard immersed tube joints 1 on both sides of the integrated immersed tube joint are respectively provided with a flexible joint 7, and each of the flexible joints 7 makes the standard immersed tube joint 1 The tube section 1 is flexible while maintaining rigidity, which is convenient for releasing internal stress of the standard immersed tube section 1 and the integrated immersed tube section after closing.

[0111] As a preferred solution of this embodiment, each of the flexible joints 7 divides the corresponding standard immersed tube section 1 into two sections. Each of the flexible joints 7 includes a closed ring-shaped first waterstop, the first waterstop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com