Hydraulic high-low temperature fluid mechanics experiment module and automatic measurement and control system

A technique of fluid mechanics and experiment, which is applied in the field of hydraulic experiment equipment and hydraulic experiment, can solve the problems of inaccuracy, inability of hydraulic pump to effectively absorb oil, inconvenience, etc., and achieve the effect of convenient fluid mechanics experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

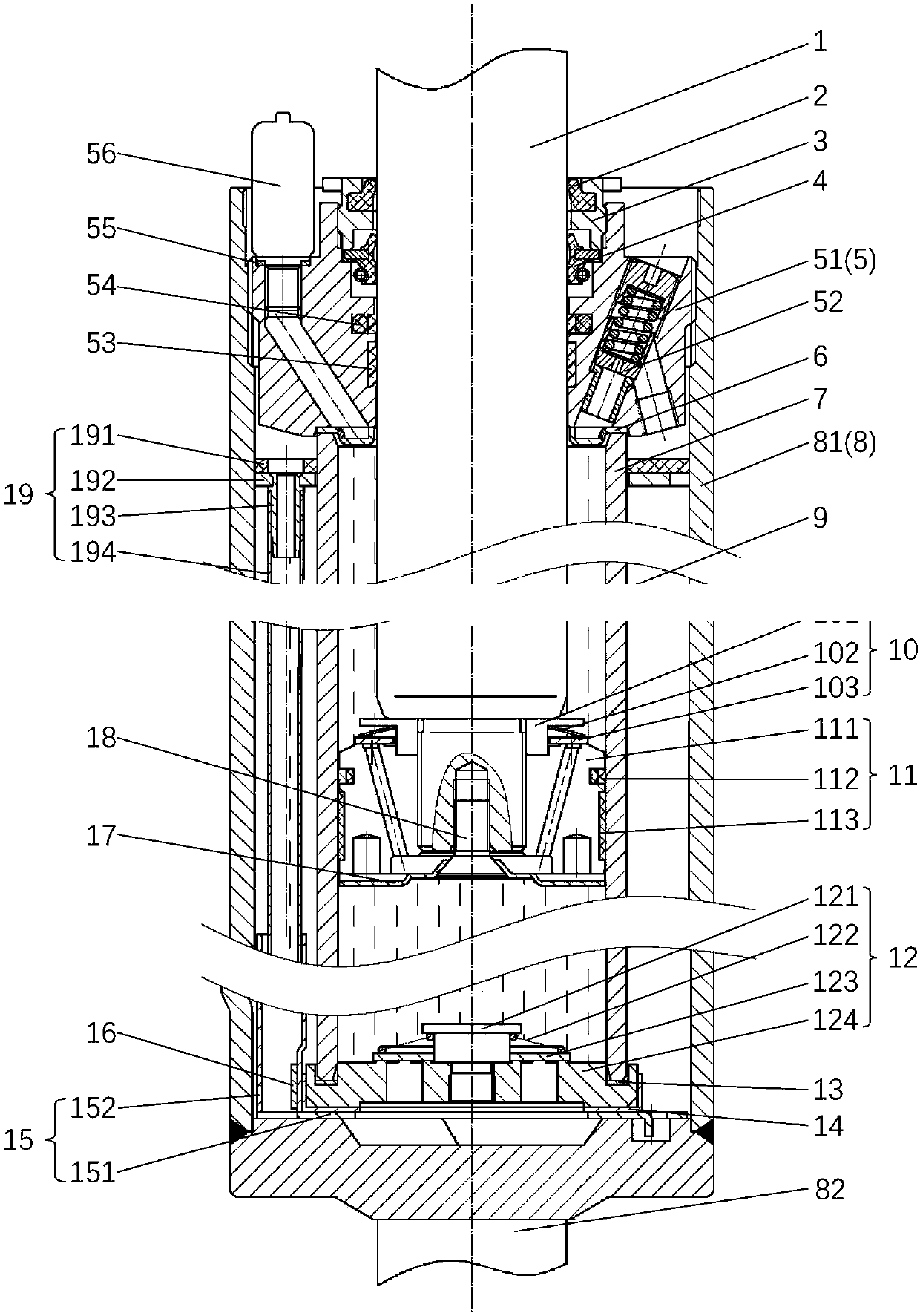

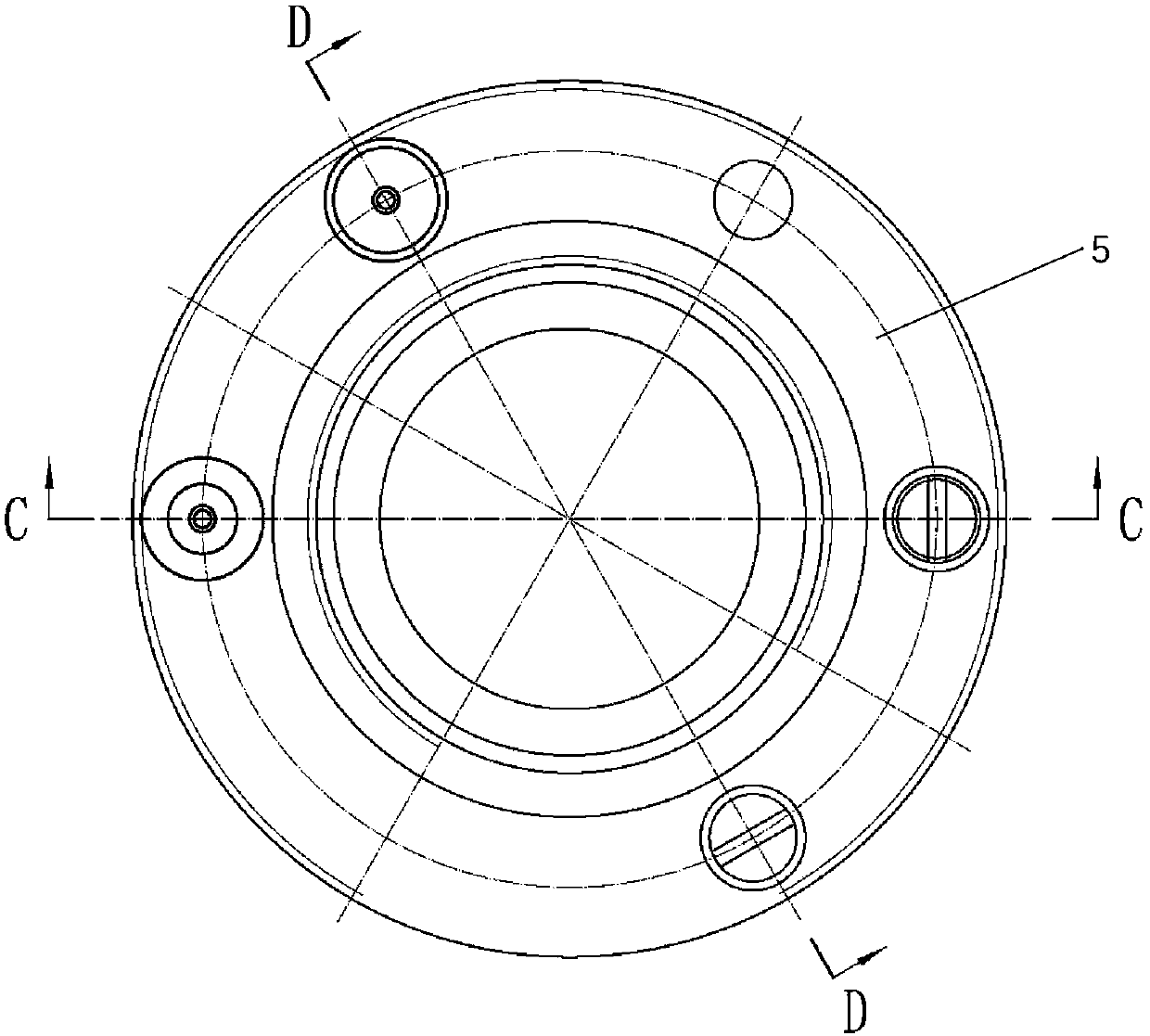

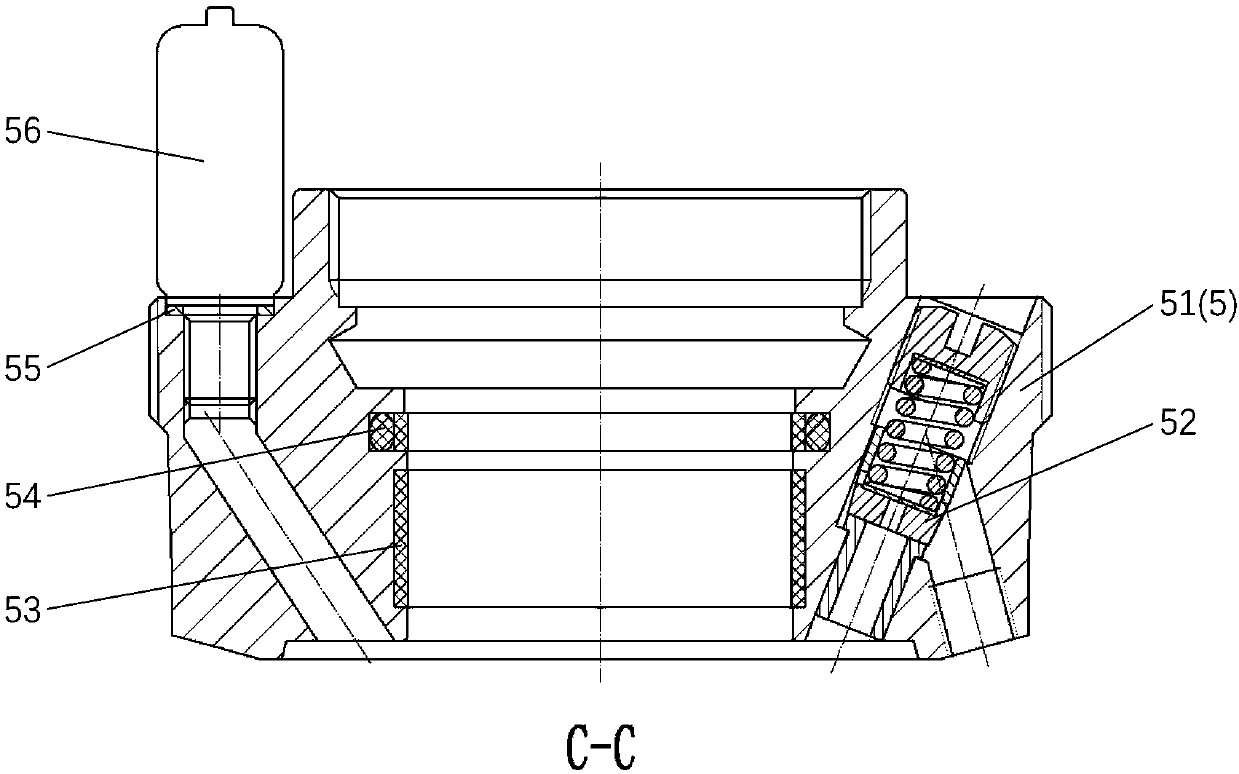

[0077] 1, Figure 1 to Figure 10 It shows an embodiment of an integrated experimental module used for high and low temperature fluid mechanics experiments of hydraulic orifices and / or gaps of the present invention. The integrated experimental module includes piston rod 1, dustproof ring 2, screw cap 3, skeleton oil seal 4, guide assembly 5, guide exhaust plate 6, pressure cylinder 7, oil storage cylinder assembly 8, hydraulic oil 9, piston Valve assembly 10, piston assembly 11, bottom valve assembly 12, pressure cylinder gasket 13, bottom valve gasket 14, oil guide plate assembly 15, magnet 16, piston exhaust plate 17, hexagonal socket head screw 18 and Oil return assembly 19.

[0078] (1) In this embodiment, the guide assembly 5 includes a guide body 51, a tested valve 52, a guide guide wear ring 53, a guide ring 54, a pressure sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com