A method of mura defect detection based on machine vision

A defect detection and machine vision technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of in-depth research on imaging systems, long time, and high detection complexity, and achieve reasonable parameter design, avoid fatigue, and robustness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

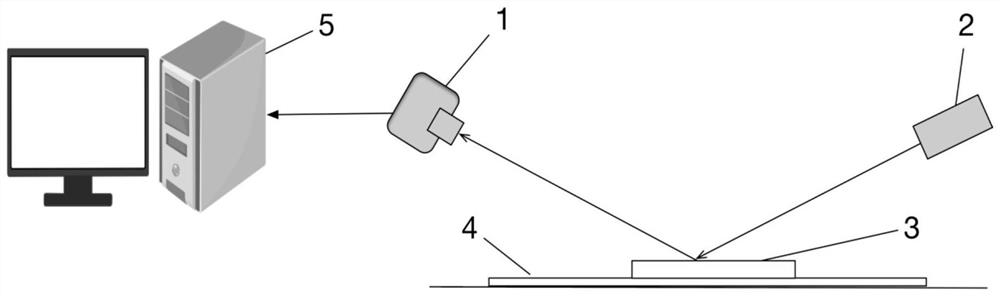

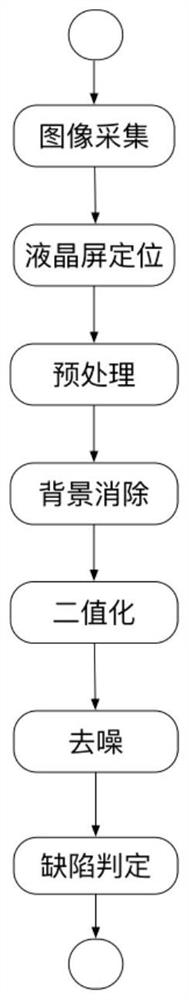

[0042] According to the attached figure 2 In the steps in the detection system of the present invention, such as image 3 The collected image I.

[0043] In this embodiment, the specific steps of the detection method of Mura defect detection based on machine vision are:

[0044] S1. Image acquisition: the linear CCD camera collects the gray image I of the LCD screen and transmits it to the defect detection and processing equipment; image 3 Shown

[0045] S2, preprocessing: use gradient threshold edge detection method for the LCD screen image I to obtain the edge of the LCD screen, segment by edge to obtain the LCD screen image P to be detected; use the 3*3 template size to perform Gaussian on the LCD screen image P Blur, get the image S to be processed;

[0046] S3. Background elimination: For image S, use the background elimination method based on domain information of Formula 1 to obtain the foreground image M: Figure 4 Shown

[0047] M(x,y)=|S(x+Δd,y)+S(x-Δd,y)+S(x,y+Δd)+S(x,y-Δd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com