High-adhesion solar cell lead-free aluminum slurry

A solar cell and high adhesion technology, applied in the field of solar cells, can solve the problems of inability to form ohmic contact between the aluminum film and the silicon substrate, reduce the cost of crystalline silicon solar cells, low warpage and strong adhesion, etc. Interconnectivity, good ohmic contact, improved printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

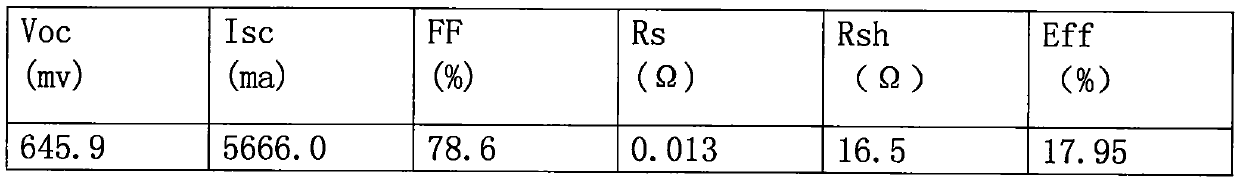

Embodiment 1

[0018] 1. Aluminum powder

[0019] Aluminum powder Aluminum powder D50 density 2.3um and aluminum powder D50 density 5.6um mixed tap density 4.7um, oxygen content is 1.3-1.8 and the shape is spherical.

[0020] 2. Preparation of organic binder

[0021] Weigh 50% of terpineol, 5% of ethyl cellulose, 40% of butyl carbitol acetate, 14% of acetate, and 5% of BYK316N and mix them evenly. After mixing the above materials, heat to 80-100°C and dissolve for 100 minutes to obtain Transparent colloid with good lubricity and printability.

[0022] 3. Preparation of lead-free glass powder

[0023] Bi 2 o 3 60 parts, Sb 2 o 3 10 copies, Sio 2 8 parts, Al 2 o 3 2 copies, V 2 o 3 2 copies, B 2 o 3 10 parts, ZnO6 parts, Zro 2 After the 2 parts are mixed evenly with a mixer, put them into a ceramic crucible, dry them in an oven at 150°C for 2 hours, put them in a muffle furnace, melt them at 1000-1200°C for 1 hour, dry them after water quenching, and then use a planetary ball mil...

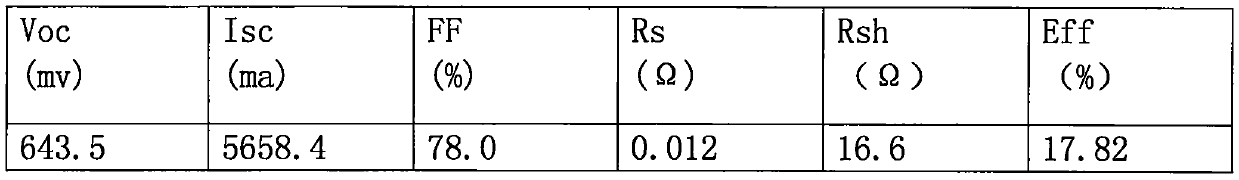

Embodiment 2

[0032] 1. Aluminum powder

[0033] Aluminum powder Aluminum powder D50 density 2.3um and aluminum powder D50 density 5.6um mixed tap density 4.7um, oxygen content is 1.3-1.8 and the shape is spherical.

[0034] 2. Preparation of organic binder

[0035] Weigh 40% of terpineol, 5% of ethyl cellulose, 35% of butyl carbitol acetate, 14% of acetate, and 5% of BYK316N and mix them evenly. After the above materials are mixed, they are heated to 80-100°C and dissolved for 100 minutes to obtain Transparent colloid with good lubricity and printability.

[0036] 3. Preparation of lead-free glass powder

[0037] Bi 2 o 3 75 parts, Sb 2 o 3 40 copies, Sio 2 6 parts, Al 2 o 3 2 copies, V 2 o 3 1 copy, B 2 o 3 12 parts, ZnO5 parts, Zro 2 After the 2 parts are mixed evenly with a mixer, put them into a ceramic crucible, dry them in an oven at 150°C for 2 hours, put them in a muffle furnace, melt them at 1000-1200°C for 1 hour, dry them after water quenching, and then use a plane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com