High-adhesion solar cell leadless aluminum paste

A technology of solar cells and high adhesion, applied in the field of solar cells, can solve the problems of low warpage and strong adhesion, great harm to the human body, low photoelectric conversion efficiency, etc., to achieve electrical performance and conversion efficiency improvement, printing process The effect of network performance improvement and improved interconnectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

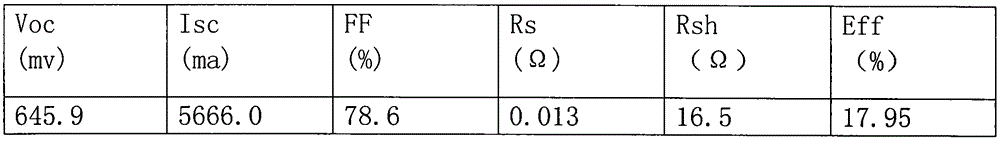

Embodiment 1

[0018] 1. Aluminum powder

[0019] Aluminum powder purity > 99.9%, 1-2um spherical aluminum powder, tap density ≥ 1.1g / cm 3 , the oxygen content is 1.3-1.8, the tap density of 3-4um spherical aluminum powder is 1.30g / cm 3 , the oxygen content is 0.6-0.9, the tap density of 5-7um spherical aluminum powder is 1.45g / cm 3 , the oxygen content is 0.30-0.40 and the shape is spherical.

[0020] 2. Preparation of organic binder

[0021] Weigh polyol 50%, cellulose 5%, polylactic acid 4%, isooctyl acrylate 4%, acrylamide 6%, surfactant 3%, turpentine 15%, organic compound 8%, sorbitan stearic acid 5% ester, after mixing the above materials, heat to 80-100°C and dissolve for 100 minutes to obtain a transparent colloid with good lubricity and printability.

[0022] 3. Preparation of lead-free glass powder

[0023] Bismuth oxide 25%, boron oxide 5%, silicon oxide 25%, zinc oxide 16%, calcium oxide 5%, antimony oxide 5%, tin oxide 5%, aluminum oxide 1%, barium carbonate 10%, lanthanum...

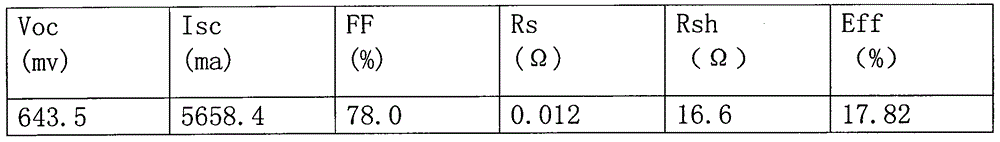

Embodiment 2

[0032] 1. Aluminum powder

[0033] Aluminum powder purity > 99.9%, 1-2um spherical aluminum powder, tap density ≥ 1.1g / cm 3 , the oxygen content is 1.3-1.8, the tap density of 3-4um spherical aluminum powder is 1.30g / cm 3 , the oxygen content is 0.6-0.9, the tap density of 5-7um spherical aluminum powder is 1.45g / cm 3 , the oxygen content is 0.30-0.40 and the shape is spherical.

[0034] 2. Preparation of organic binder

[0035] Polyol 55%, Cellulose 5%, Polylactic Acid 4%, Isooctyl Acrylate 4%, Acrylamide 6%, Surfactant 3%, Turpentine 10%, Organic Compound 7%, Sorbitan Stearate 6 %, the above materials are mixed and heated to 80-100°C to dissolve for 100 minutes to obtain a transparent colloid with good lubricity and printability.

[0036] 3. Preparation of lead-free glass powder

[0037] Bismuth oxide 20%, boron oxide 8%, silicon oxide 22%, zinc oxide 20%, calcium oxide 4%, antimony oxide 5%, tin oxide 5%, aluminum oxide 1%, barium carbonate 12%, lanthanum oxide 3%, Af...

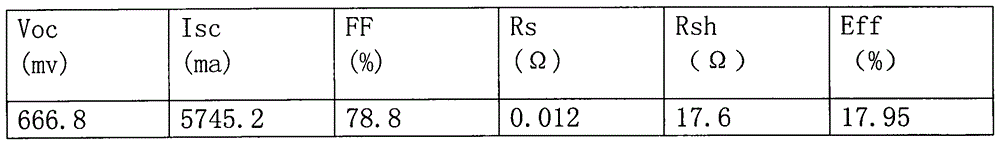

Embodiment 3

[0046] 1. Aluminum powder

[0047] Aluminum powder purity > 99.9%, 1-2um spherical aluminum powder, tap density ≥ 1.1g / cm 3 , the oxygen content is 1.3-1.8, the tap density of 3-4um spherical aluminum powder is 1.30g / cm 3 , the oxygen content is 0.6-0.9, the tap density of 5-7um spherical aluminum powder is 1.45g / cm 3 , the oxygen content is 0.30-0.40 and the shape is spherical.

[0048] 2. Preparation of organic binder

[0049] Polyol 60%, Cellulose 6%, Polylactic Acid 4%, Isooctyl Acrylate 4%, Acrylamide 6%, Surfactant 3%, Turpentine 10%, Organic Compound 5%, Sorbitan Stearate 2 %, the above materials are mixed and heated to 80-100°C to dissolve for 100 minutes to obtain a transparent colloid with good lubricity and printability.

[0050] 3. Preparation of lead-free glass powder

[0051] Bismuth oxide 22%, boron oxide 7%, silicon oxide 23%, zinc oxide 17%, calcium oxide 4%, antimony oxide 5%, tin oxide 5%, aluminum oxide 1.5%, barium carbonate 11%, lanthanum oxide 4.5%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com