Metal surface heat preservation and insulation coating and preparation method and application method thereof

A metal surface, thermal insulation technology, applied in epoxy resin coatings, reflective/signal coatings, coatings, etc., can solve the problem of rising surface temperature, increase the power consumption of refrigeration facilities such as air conditioners, fans and refrigerators, and affect the comfort of life. To achieve the effect of enhanced thermal insulation performance, good thermal insulation effect, and tight membrane structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention discloses a method for preparing a metal surface thermal insulation coating, which comprises the following steps:

[0050] In parts by weight, 70-80 parts of PVDF resin, 5-10 parts of aqueous epoxy resin solution, 10-20 parts of diluent and 0.01-1 part of leveling agent are placed in the mixer at a suitable speed (90- 150r / min) to stir and mix (5-10min) to make an emulsion, then add 1-10 parts of hollow glass microspheres, 5-10 parts of ytterbium modified nanopowder, and 3-5 parts of titanium dioxide powder to the emulsion 2-10 parts of rare earth, 0-5 parts of negative ion powder and 8-15 parts of polyvinyl alcohol, stir evenly (25-35min) at a suitable speed (260-320r / min) and then stand still, filter (100- 150 mesh sieve) to make the required metal surface thermal insulation coating, wherein, the interval stirring time of adding the preparation raw materials each time is 3-15min.

[0051] The invention also discloses the application of the metal surface...

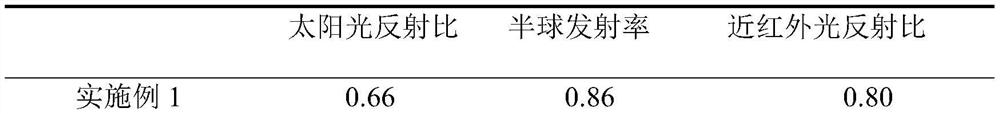

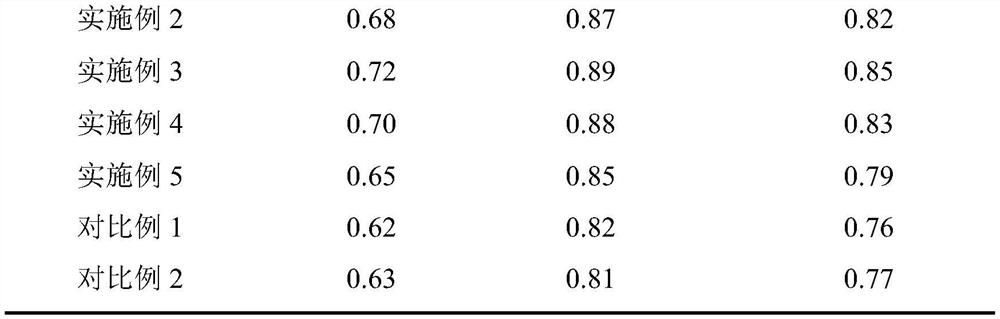

Embodiment 1

[0057] The invention discloses a method for preparing a metal surface thermal insulation coating, which comprises the following steps:

[0058] First, 70 parts of French Arkema company Kynar370 type PVDF resin, 10 parts of water-based epoxy resin solution, 0.05 parts of American DuPont CapstoneFS-3100 type leveling agent and 18 parts of dimethyl formamide diluent were placed in the mixer at 100r / The speed of min was stirred for 5 minutes, mixed evenly, and then added 1 part of 3M company VS5500 type glass microspheres, 10 parts of ytterbium modified nano-alumina powder, 3 parts of R105 type titanium dioxide powder produced by DuPont, 6 parts of rare earth (titanium acid rare earth), 3 parts of negative ion powder, 10 parts of polyvinyl alcohol and 5 parts of Hangzhou Hengna New Material Co., Ltd. HN-R50Y3 type zirconia ceramic powder, stirred at a speed of 300r / min for 30min and left to stand, then used a 150-mesh filter Filtration is carried out to make the required metal su...

Embodiment 2

[0063] The invention discloses a method for preparing a metal surface thermal insulation coating, which comprises the following steps:

[0064] First, 70 parts of French Arkema company Kynar370 type PVDF resin, 10 parts of water-based epoxy resin solution, 0.05 parts of American DuPont CapstoneFS-3100 type leveling agent and 18 parts of dimethyl formamide diluent were placed in the mixer at 100r / Min speed stirring for 5min, mixed evenly, then add 3 parts of 3M company VS5500 glass microspheres, 10 parts of ytterbium modified nano-alumina powder, 3 parts of R105 titanium dioxide powder produced by DuPont, 6 parts of rare earth, 3 parts 1 part of negative ion powder, 10 parts of polyvinyl alcohol and 5 parts of Hangzhou Hengna New Material Co., Ltd. HN-R50Y3 type zirconia ceramic powder, stirred at a speed of 300r / min for 30min and left to stand, followed by filtering with a 150-mesh filter screen to obtain the Thermal insulation coatings for metal surfaces are required, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com