Preparation method of low-viscosity epoxy resin and ultra-leveling powder coating

A technology of epoxy resin and powder coating, applied in the field of coatings, can solve the problems that the leveling and gloss of the coating film are difficult to compare with paints, and the viscosity of the resin is high, so as to achieve excellent leveling, improve performance, and improve leveling and gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of low-viscosity epoxy resin, the steps are as follows:

[0028] Add 160 parts by weight of liquid epoxy resin into the three-necked flask, heat up to 120-130°C while stirring mechanically, add 72 parts by weight of bisphenol A, and control the temperature at 130 °C after the epoxy resin and bisphenol A are completely miscible. ±2°C, add quaternary ammonium salt catalyst, react at 150-160°C for 3 hours, pour the reaction product out of a three-necked flask, and cool to obtain a low-viscosity epoxy resin.

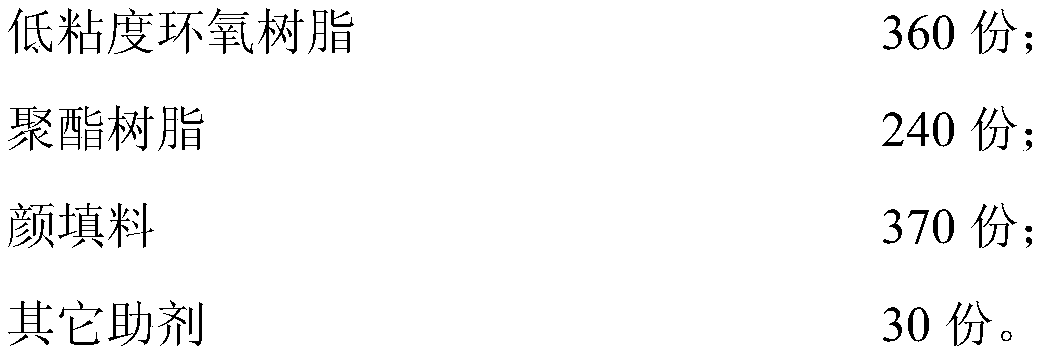

[0029] Utilize the super-leveling powder coating of the low-viscosity epoxy resin that the preparation method of above-mentioned low-viscosity epoxy resin makes, its composition and parts by weight are as follows:

[0030]

Embodiment 2

[0032] A preparation method of low-viscosity epoxy resin, the steps are as follows:

[0033] Add 170 parts by weight of liquid epoxy resin into the three-necked flask, heat up to 120-130°C while stirring mechanically, add 80 parts by weight of bisphenol A, and control the temperature at 130 °C after the epoxy resin and bisphenol A are completely miscible. ±2°C, add quaternary ammonium salt catalyst, react at 150-160°C for 2.5 hours, pour the reaction product out of a three-necked flask, cool down, and obtain a low-viscosity epoxy resin.

[0034] Preferably, the liquid epoxy resin is bisphenol F epoxy resin, epoxy equivalent (160-180) g / eq, viscosity (700-1200) cps@25°C.

[0035] Utilize the super-leveling powder coating that the preparation method of above-mentioned low-viscosity epoxy resin makes, its composition and parts by weight are as follows:

[0036]

[0037] Preferably, the polyester resin is a carboxyl-terminated polyester resin with an acid value of 47-51 mgKOH / ...

Embodiment 3

[0041] A preparation method of low-viscosity epoxy resin, the steps are as follows:

[0042] Add 165 parts by weight of liquid epoxy resin into the three-necked flask, heat up to 120-130°C while stirring mechanically, add 83 parts by weight of bisphenol A, and control the temperature at 130 °C after the epoxy resin and bisphenol A are completely miscible. Add a quaternary ammonium salt catalyst at ±2°C, react at 150-160°C for 2.5 hours, pour the reaction product out of a three-necked flask, and cool to obtain a low-viscosity epoxy resin.

[0043] Preferably, the liquid epoxy resin is bisphenol F epoxy resin, epoxy equivalent (160-180) g / eq, viscosity (700-1200) cps@25°C.

[0044] Preferably, the quaternary ammonium salt catalyst is added in parts by weight of 0.07-0.2 parts;

[0045] The number-average relative molecular mass of the low-viscosity epoxy resin is 2500-4500, and the epoxy equivalent is (780-950) g / eq.

[0046] Utilize the super-leveling powder coating that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com