Level converting circuit

A technology for converting circuits and levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

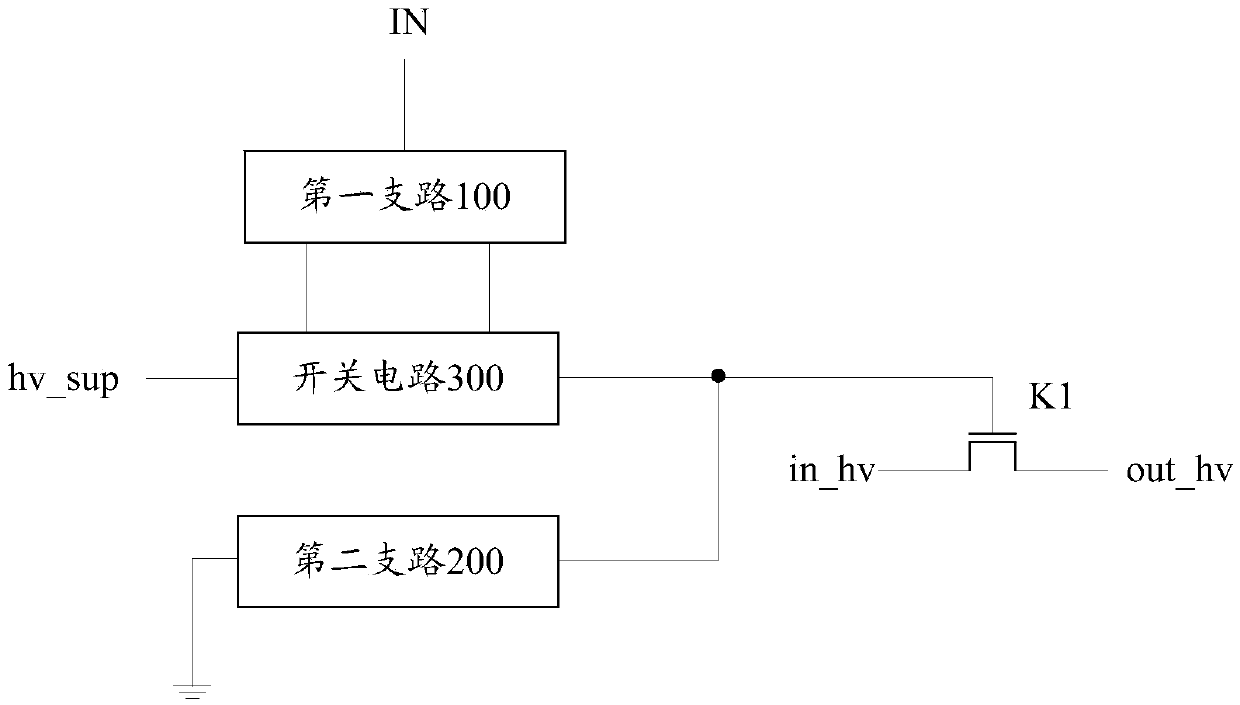

[0062] see figure 2 , which is a schematic structural diagram of a level conversion circuit provided in an embodiment of the present application.

[0063] The level conversion circuit provided in the embodiment of the present application includes: a first branch circuit 100, a second branch circuit 200, a switch circuit 300 and a first switch tube K1;

[0064] The input terminal of the first branch 100 is the input terminal IN of the level conversion circuit, the first output terminal of the first branch 100 is connected to the first control terminal of the switch circuit 300, and the second output terminal of the first branch 100 is connected to the switch A second control terminal of the circuit 300;

[0065] The first end of the switch circuit 300 is connected to the first auxiliary power supply hv_sup, the second end of the switch circuit 300 is connected to the first end of the second branch 200, and the second end of the second branch 200 is grounded;

[0066] The con...

Embodiment 2

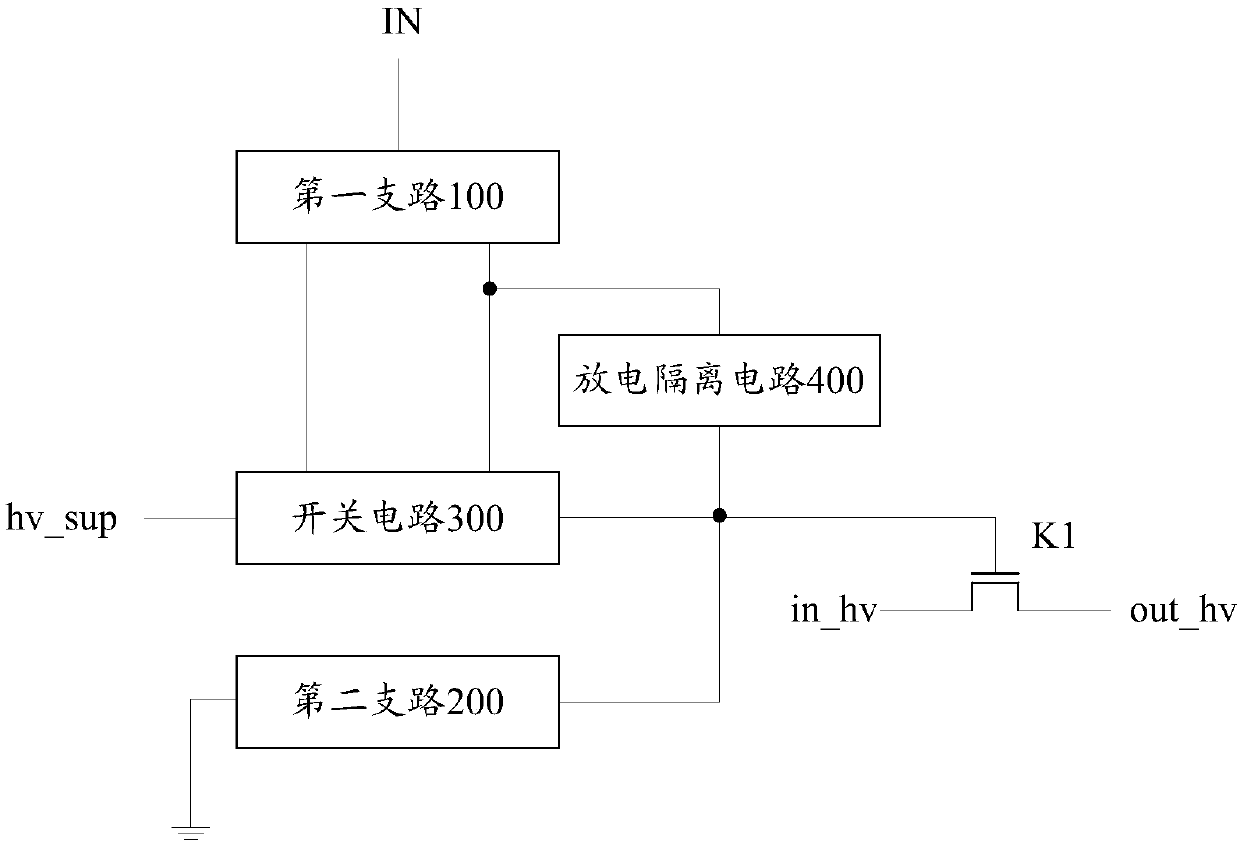

[0072] see image 3 , which is a schematic structural diagram of another level conversion circuit provided in the embodiment of the present application. Compared to figure 2 , this figure provides a more concrete level shifting circuit.

[0073] In the embodiment of the present application, the level conversion circuit may further include: a discharge isolation circuit 400;

[0074] A first end of the discharge isolation circuit 400 is connected to the first output end of the first branch 100 , and a second end of the discharge isolation circuit 400 is connected to the first end of the second branch 200 .

[0075] When the input terminal IN of the level conversion circuit turns to a low level, the discharge isolation circuit 400 can isolate the switch circuit 300 and the control terminal of the first switch tube K1 to discharge through the first branch 100 and the second branch 200 respectively; When the input terminal IN of the level conversion circuit inputs a high level...

Embodiment 3

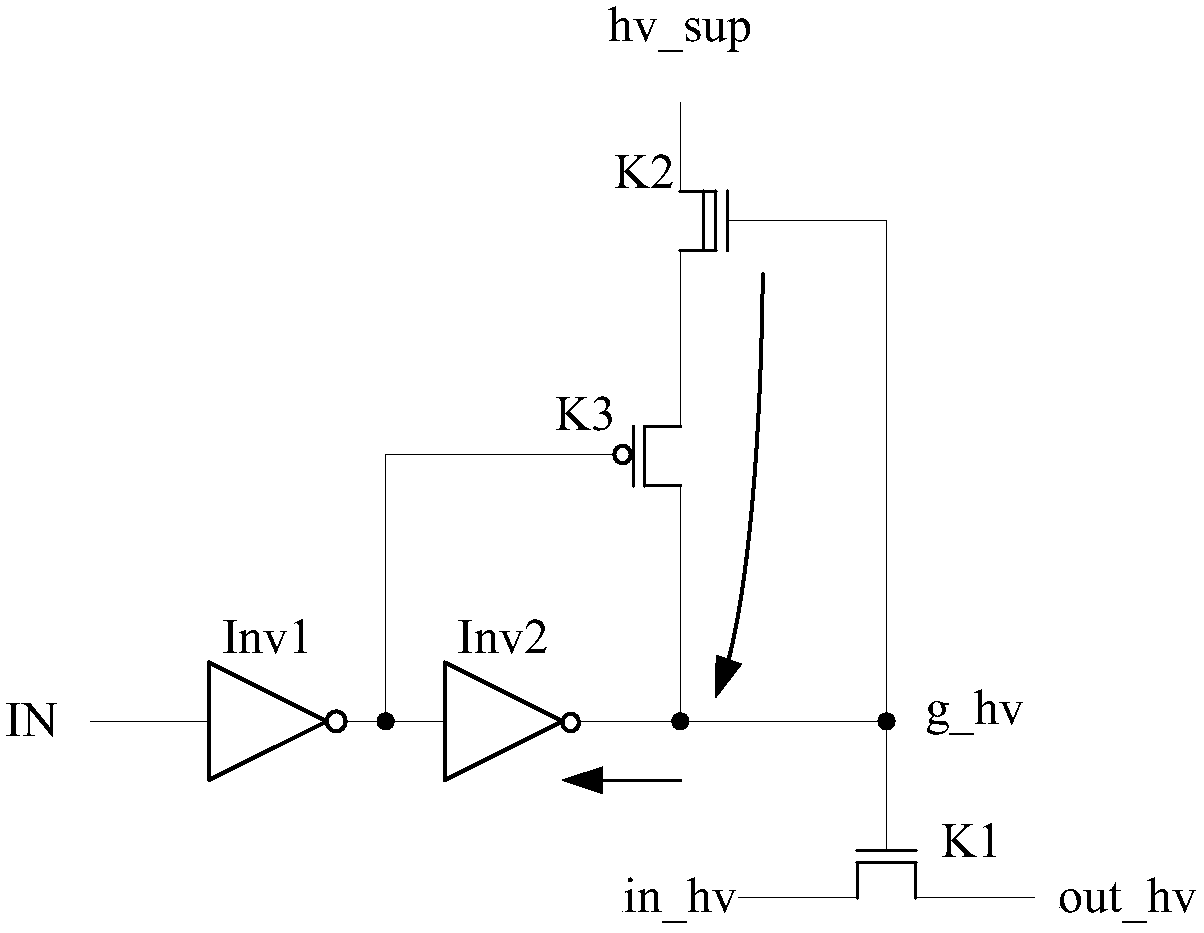

[0086] see Figure 5 , which is a circuit topology diagram of a level conversion circuit provided in a specific embodiment of the present application. Compared to figure 2 and image 3 , this figure provides a more concrete level shifting circuit.

[0087] Figure 5 The circuit topology of the level conversion circuit provided by the specific embodiment of the present application is shown only by taking the discharge isolation circuit including an isolation resistor R as an example. The two ends of the isolation resistor R are respectively connected to the first output end of the first branch and the second branch. The second end of the circuit, other implementations of the discharge isolation circuit will not be listed here.

[0088] In the embodiment of the present application, the first branch may specifically include: a first inverter Inv1 and a second inverter Inv2;

[0089] The input end of the first inverter Inv1 is the input end of the first branch, and the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com