Welding tool for power module

A power module and welding tooling technology, which is applied to welding equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of difficult disassembly, cumbersome welding and assembly, etc., and achieve the effect of solving difficult disassembly, convenient disassembly of tooling, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

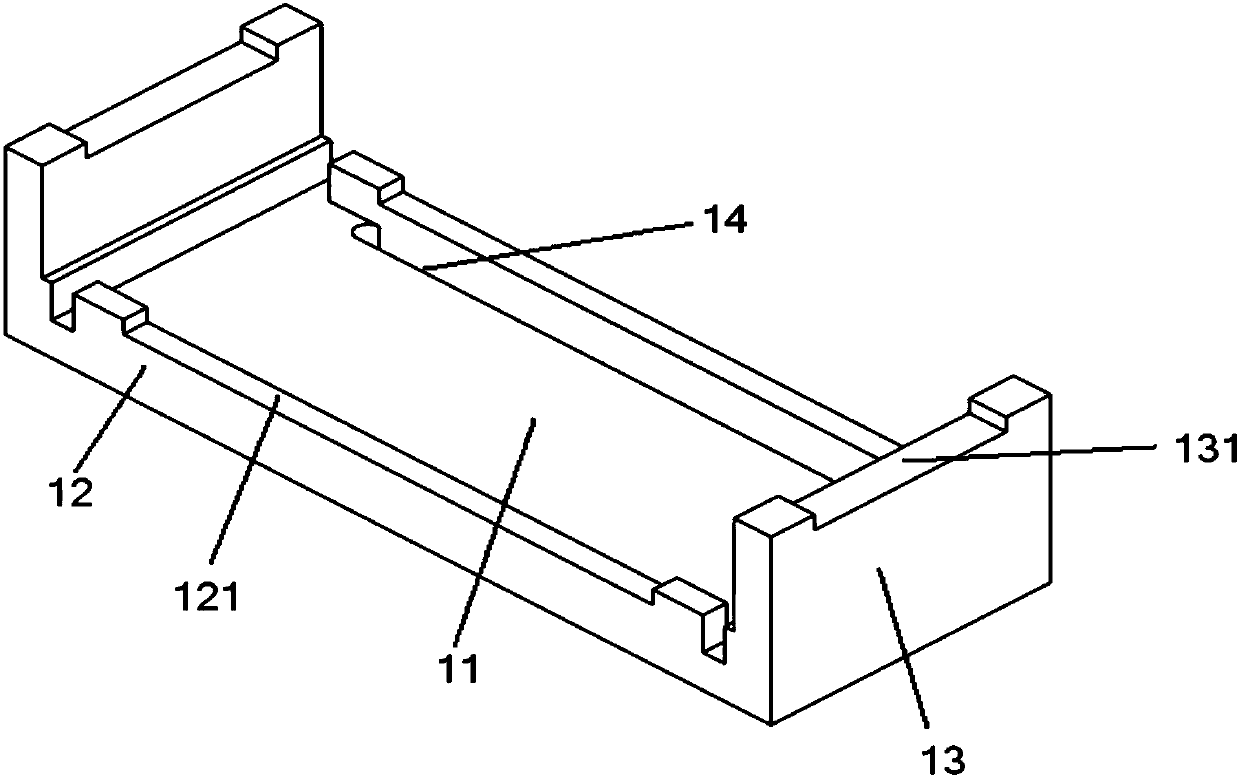

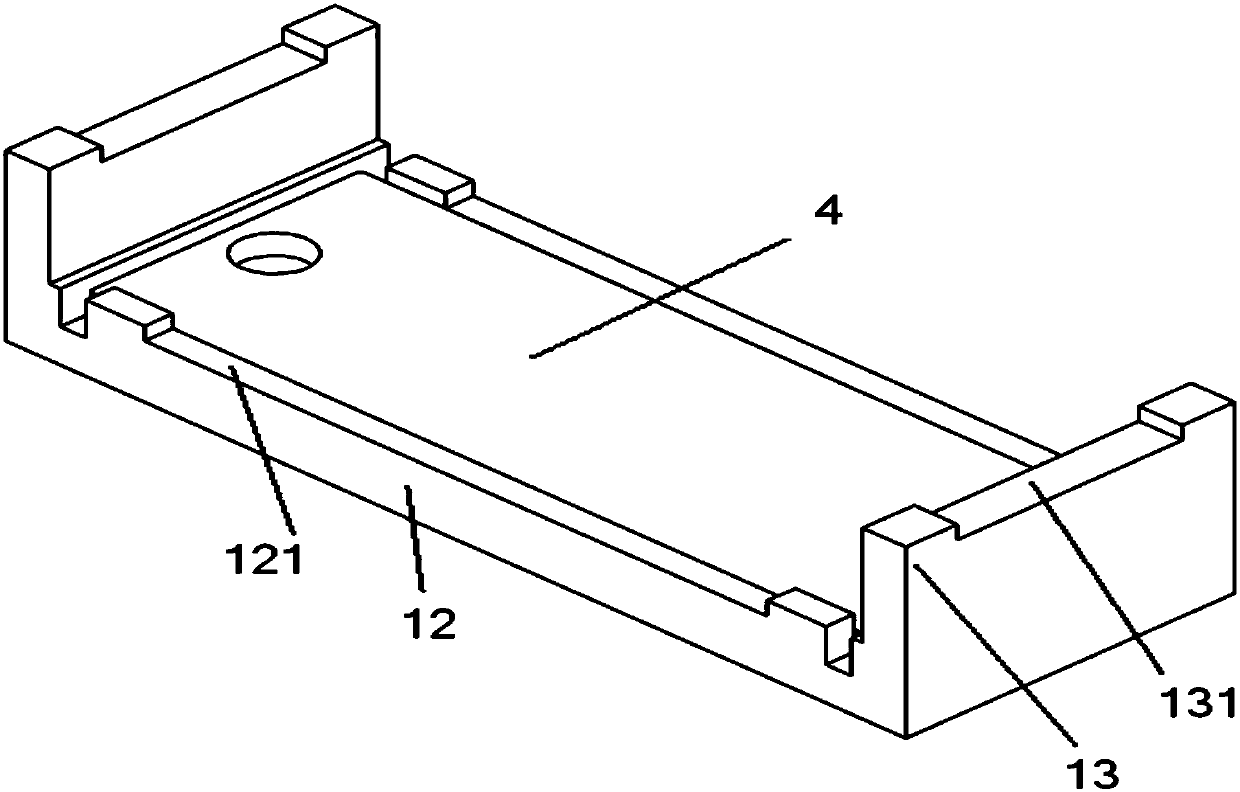

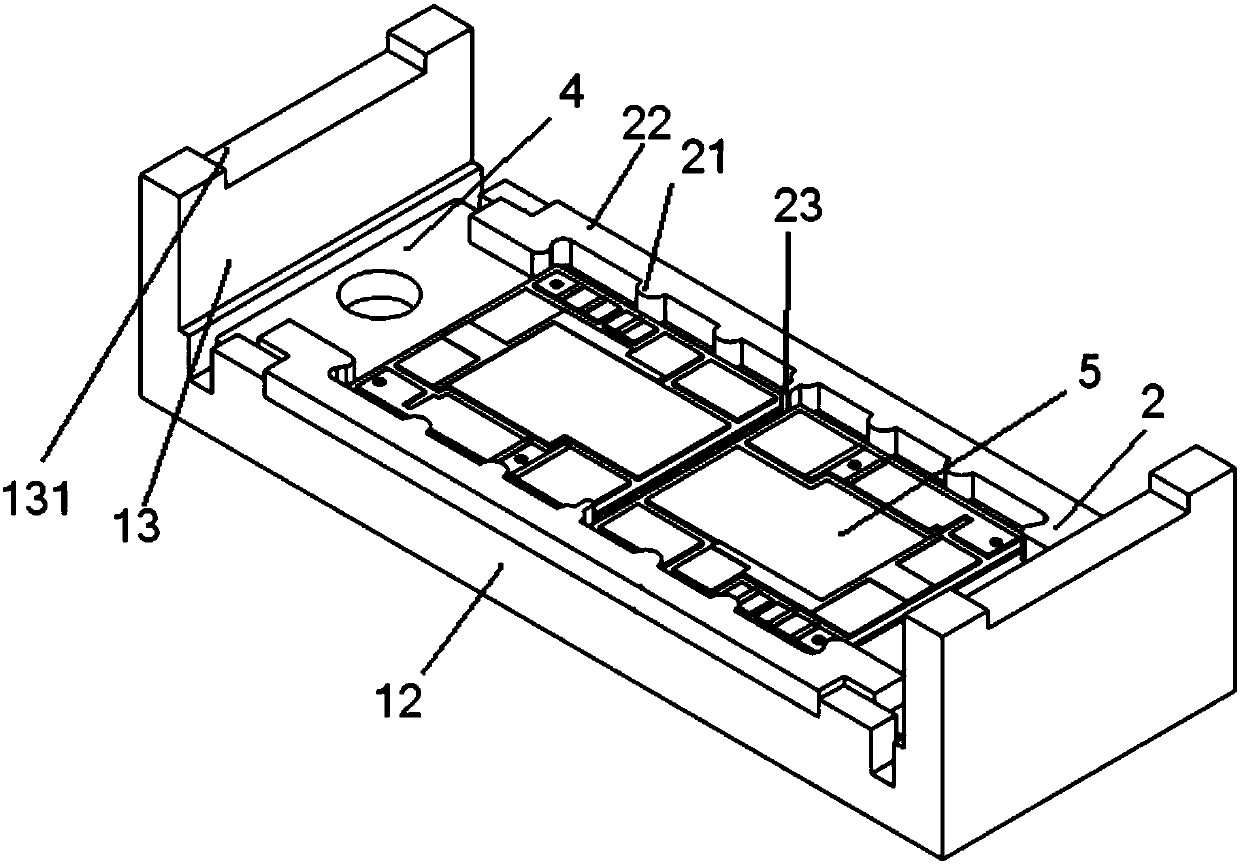

[0028] In a preferred embodiment of the present invention, as Figure 1-4 As shown, a power module welding tool, including:

[0029] Copper bottom plate positioning tool 1, such as figure 1 As shown, it includes a rectangular bottom plate 11, two first baffle plates 12 extending upwards at the two long sides of the bottom plate 11, and two second baffles 13 extending upward at the two short sides of the bottom plate respectively, The second baffle 13 is higher than the first baffle 12; as figure 2 As shown, the copper base plate positioning tool 1 is used to position the copper base plate 4 of the power module to be welded. The copper base plate 4 is placed on the base plate 11 and completely covers the base plate 11. Base plate for positioning;

[0030] Copper clad laminate positioning too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com