Method for synthesizing alkylphenol formaldehyde curing resin in catalytic mode through organic alkali

A vulcanized resin and alkylphenol technology, which is applied in the field of alkylphenol formaldehyde vulcanized resins catalyzed by organic strong bases, can solve the problems of low methylol, poor vulcanization performance, and long working hours of vulcanized resins, and achieve good vulcanization performance, Good performance, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

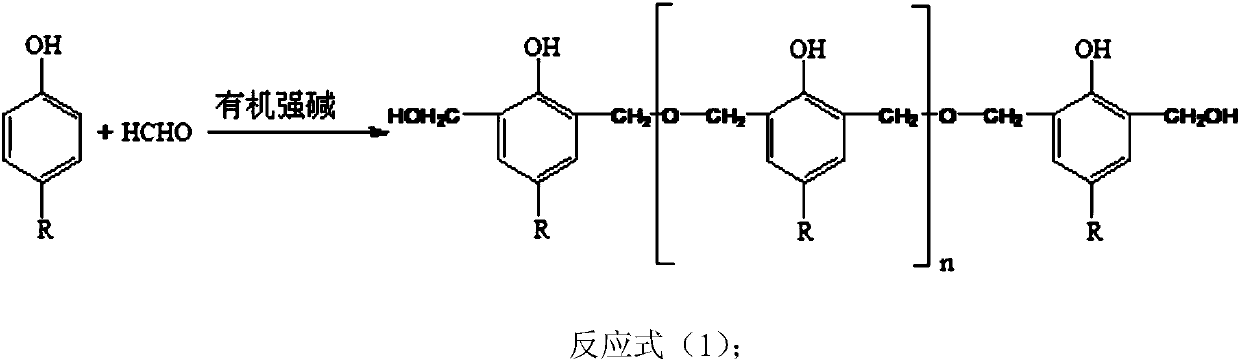

Method used

Image

Examples

Embodiment 1

[0021] In the 1000ml four-neck flask with stirring, thermometer and condenser, drop into 268g p-tetraoctylphenol, 47g tetramethylammonium hydroxide aqueous solution (tetramethylammonium hydroxide content 25%), be heated to p-tetraoctylphenol Melt completely, start stirring, heat to 80°C, add 211g of liquid formaldehyde (formaldehyde content 37%) dropwise within 30 minutes, react at 80°C for 2 hours, add 268g of toluene, stir for 20min and separate layers, keep the lower water layer , the catalyst inside can be used for the next reaction; for the upper toluene resin layer, toluene is recovered at normal pressure, and after reaching 135°C, vacuumize to -0.095Mpa. Resin, resin softening point is 87.5°C.

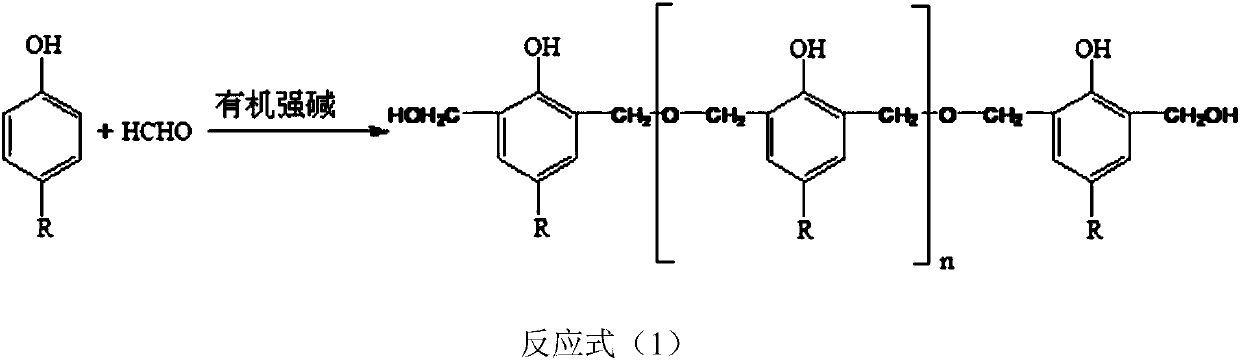

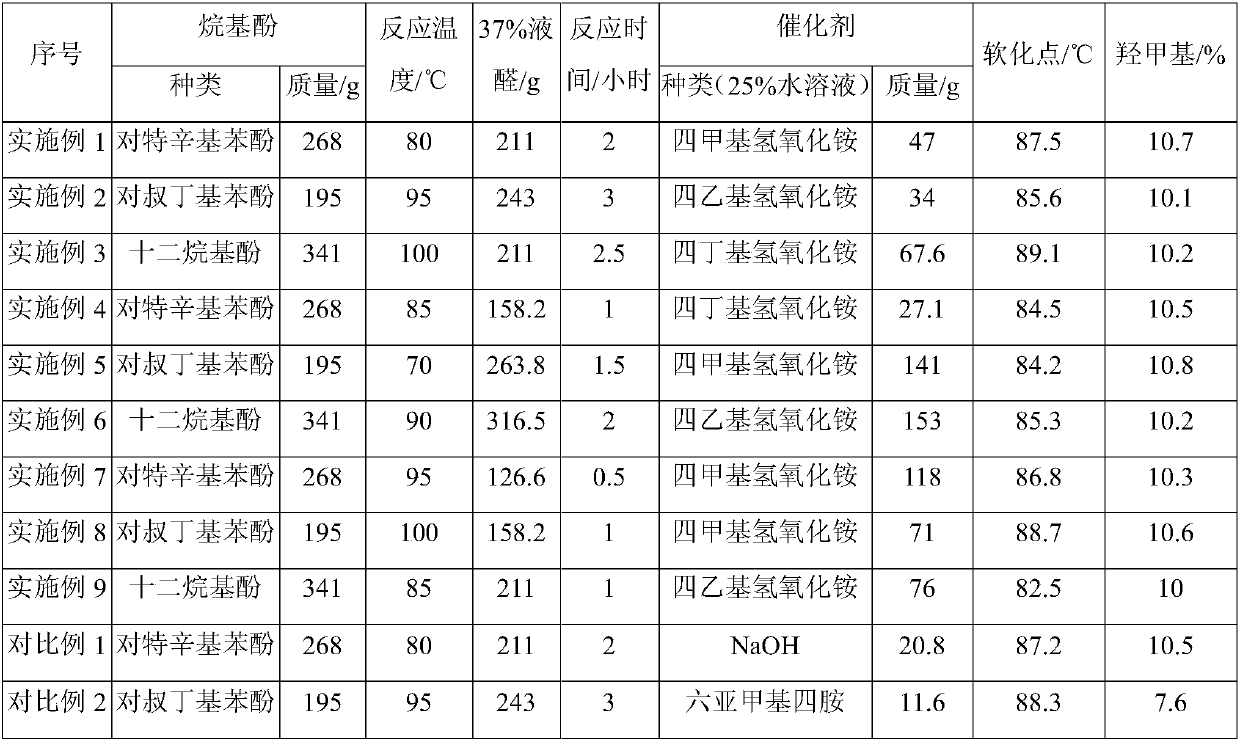

[0022] For other Examples 2-9 and comparative examples, see Example 1 for the implementation steps, and see Table 1 for the implementation conditions.

[0023] Table 1

[0024]

[0025] As can be seen from Table 1, embodiment 1~9 is to make catalyzer with organic strong bas...

Embodiment 10

[0027] The products prepared in Examples 1, 2, 7, and 9 were used in rubber for application testing, and compared with the alkylphenol-formaldehyde vulcanized resins synthesized in Comparative Example 1 and Comparative Example 2. The formulation of the rubber composition is shown in Table 2. The test results are shown in Table 3. As can be seen from Table 3, the alkylphenol-formaldehyde vulcanized resin of the present invention, compared with Comparative Example 2, has significantly improved vulcanization properties, mechanical properties and tear resistance; compared with Comparative Example 1, each index is almost the same big.

[0028] Table 2

[0029] serial number

parts by mass

1

IIR

100.00

2

CR

5.00

3

N375

60.00

4

6.00

5

ZnO

5.00

6

Embodiment 1,2,7,9 product, comparative example

10.00

7

B WAX

1.00

[0030] table 3

[0031]

[0032...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com