A Vibration Shock Extrusion Method for Eliminating Weld Residual Stress and Negative Stress in Weld

A residual stress and impact extrusion technology, applied in the field of vibration impact extrusion, to achieve the effect of improving surface cleanliness, smooth surface, and no increase in production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] There are many ways to generate vibration and impact force in the axial direction of the extrusion wheel, such as the hole-type rotating wheel device of the impact electric drill, such as the crank connecting rod device, such as electromagnetic vibration, etc.

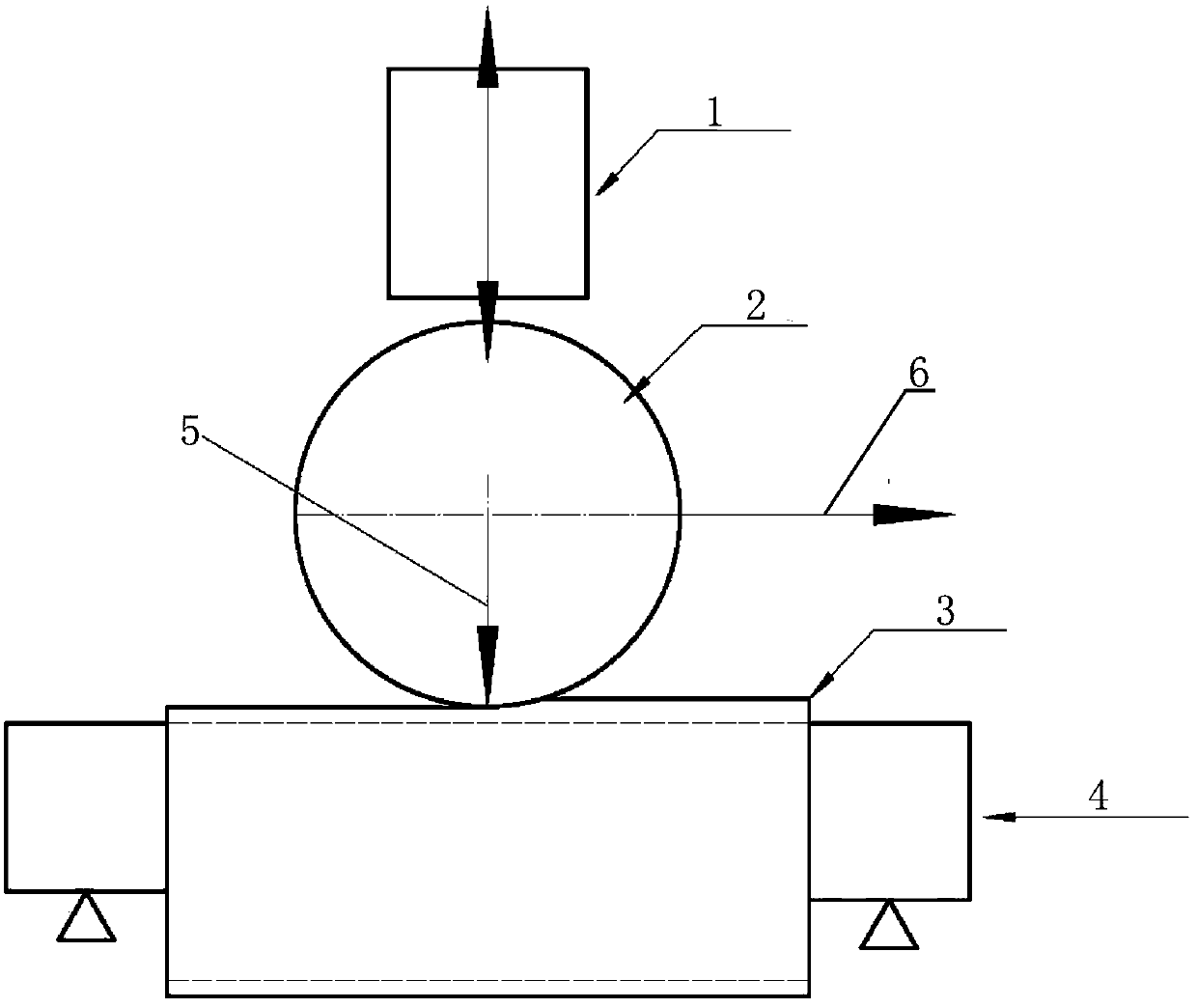

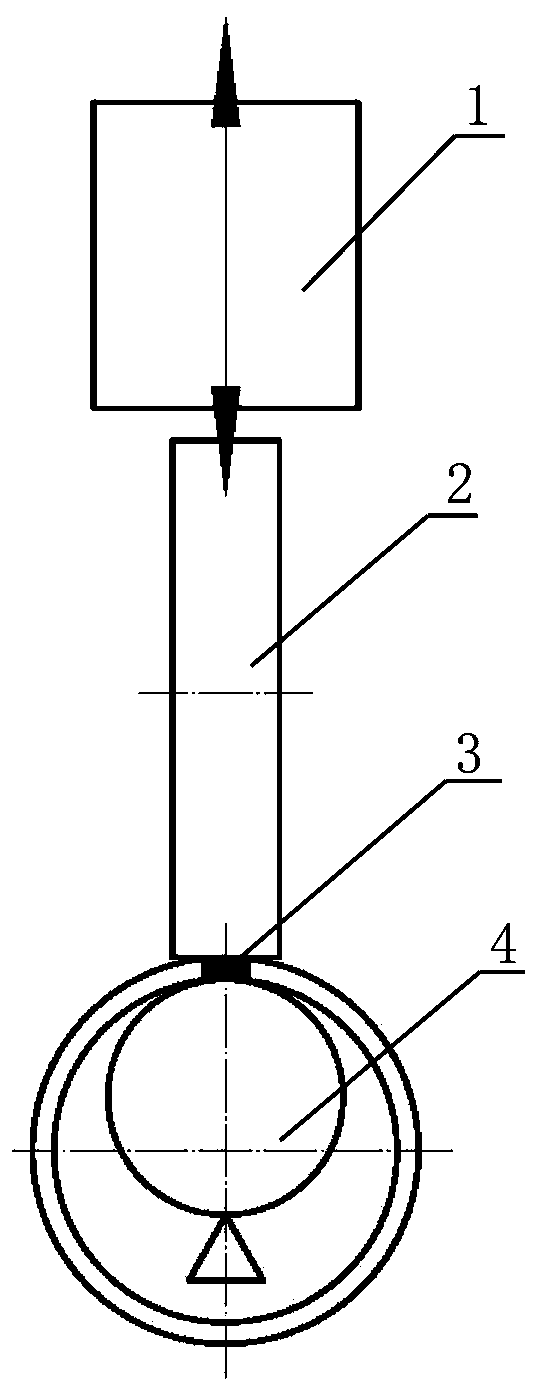

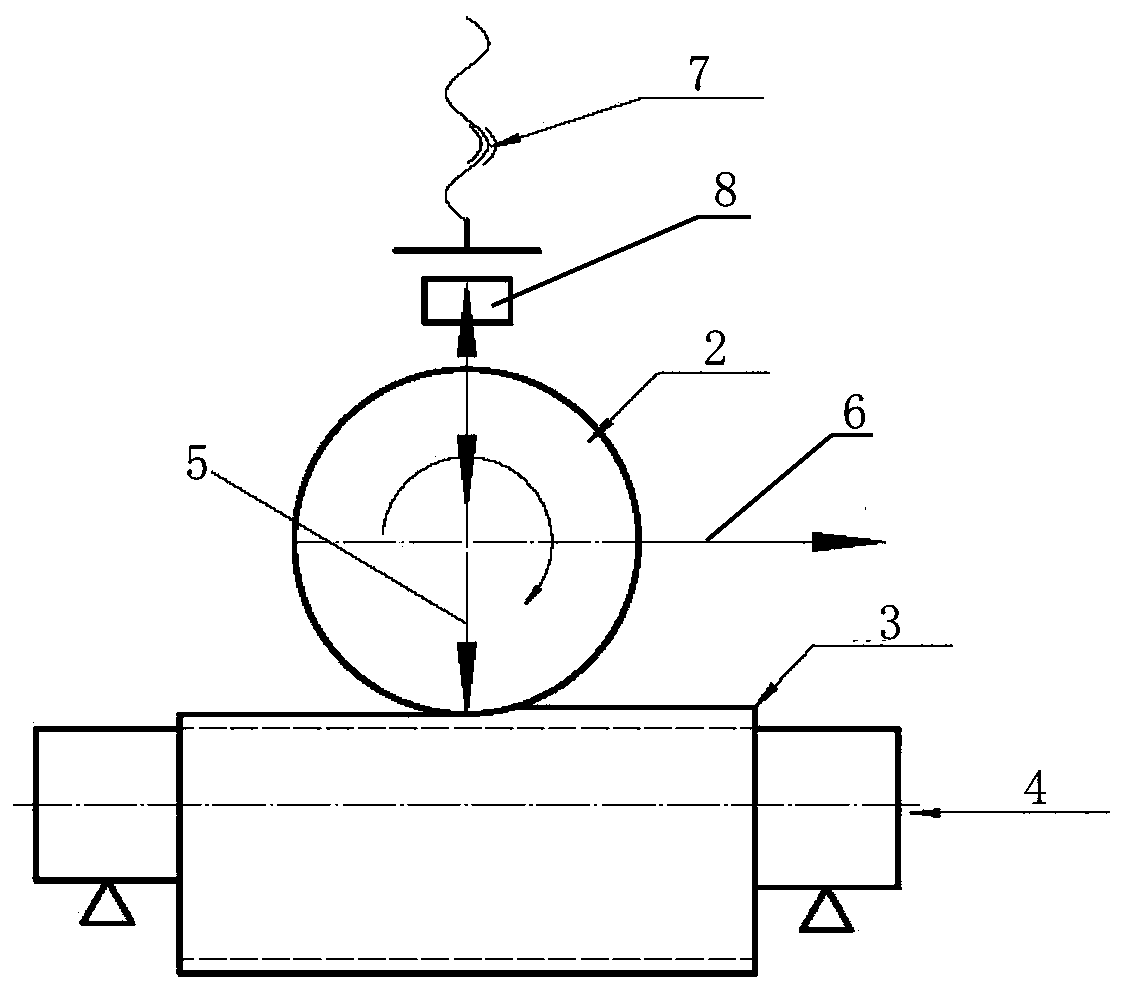

[0025] Such as image 3 and Figure 4 As shown in the schematic diagram, it is a structural schematic diagram of a vibration and impact force generating device with an eccentric wheel structure to eliminate the residual stress of the weld, which is used to represent the working principle of the specific vibration and impact extrusion device. The welded pipe is supported by the support shaft 4, The welding seam of the pipe is vertically upward, and the welded pipe is provided with a squeeze wheel 2, and the curved surface and curvature radius of the squeeze wheel 2 and the support shaft 4 are adapted to the radius of the welded pipe; a bearing is arranged along the central axis of the squeeze wheel 2 9. The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com