Rotary output double-mass-block tuning fork angular rate gyroscope

An angular rate gyro and dual-mass technology, which is applied to gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc., can solve problems such as the difficulty of vertical torsion bar processing, and achieve suppression of interference modes and reduction Capacitance change, effect of reducing influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

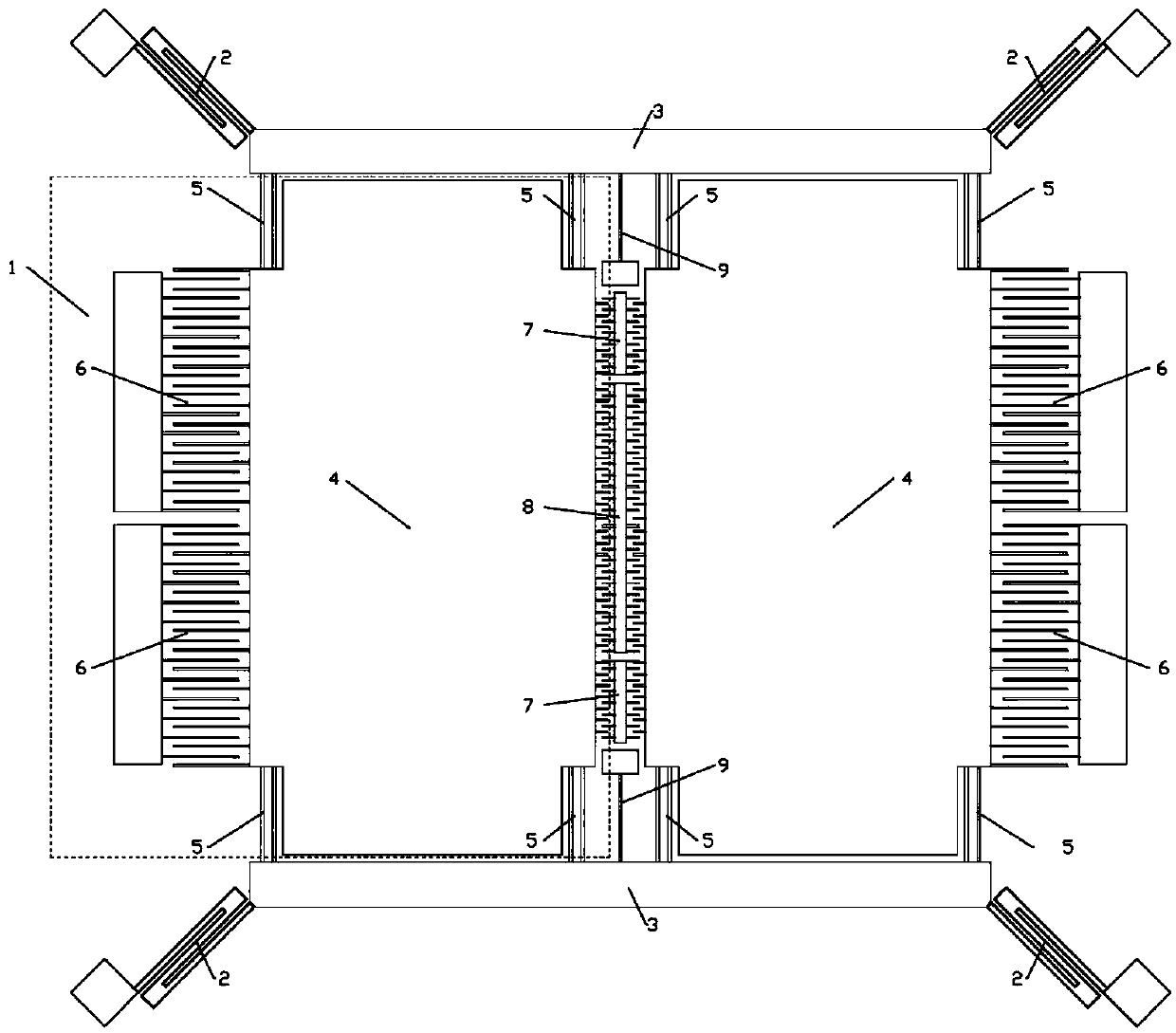

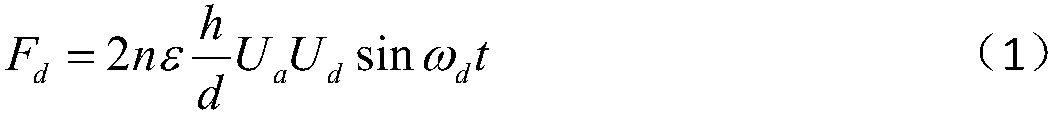

[0017] combine Figure 1 to Figure 2 , a dual-mass tuning fork angular rate gyroscope with rotational output, used to measure the angular rate in the Z-axis direction. It includes an upper vacuum packaging cover plate, a lower silicon substrate and a middle single crystal silicon chip, and a gyro mechanical structure is arranged on the middle layer single crystal silicon chip. The present invention adopts wafer-level vacuum encapsulation technology, the upper vacuum encapsulation cover plate, the middle single crystal silicon wafer and the lower silicon substrate are made of silicon material, and a closed vacuum cavity is formed between the upper vacuum encapsulation cover plate and the lower silicon substrate , the middle single crystal silicon wafer is arranged in the vacuum cavity, so that the mechanical structure of the gyroscope is suspended above the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com