Shoe-tree rough blanks, strips of shoe-tree rough blanks and shoe tree processing method using shoe-tree rough blanks

A technology of shoe lasts and rough blanks, which is applied in shoe lasts, applications, footwear, etc., can solve the problems of insufficient versatility of shoe last rough blanks, high difficulty in forming shoe last rough blanks, and increased difficulty in making molds, and achieve the The effect of abundant quantity, simple structure and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

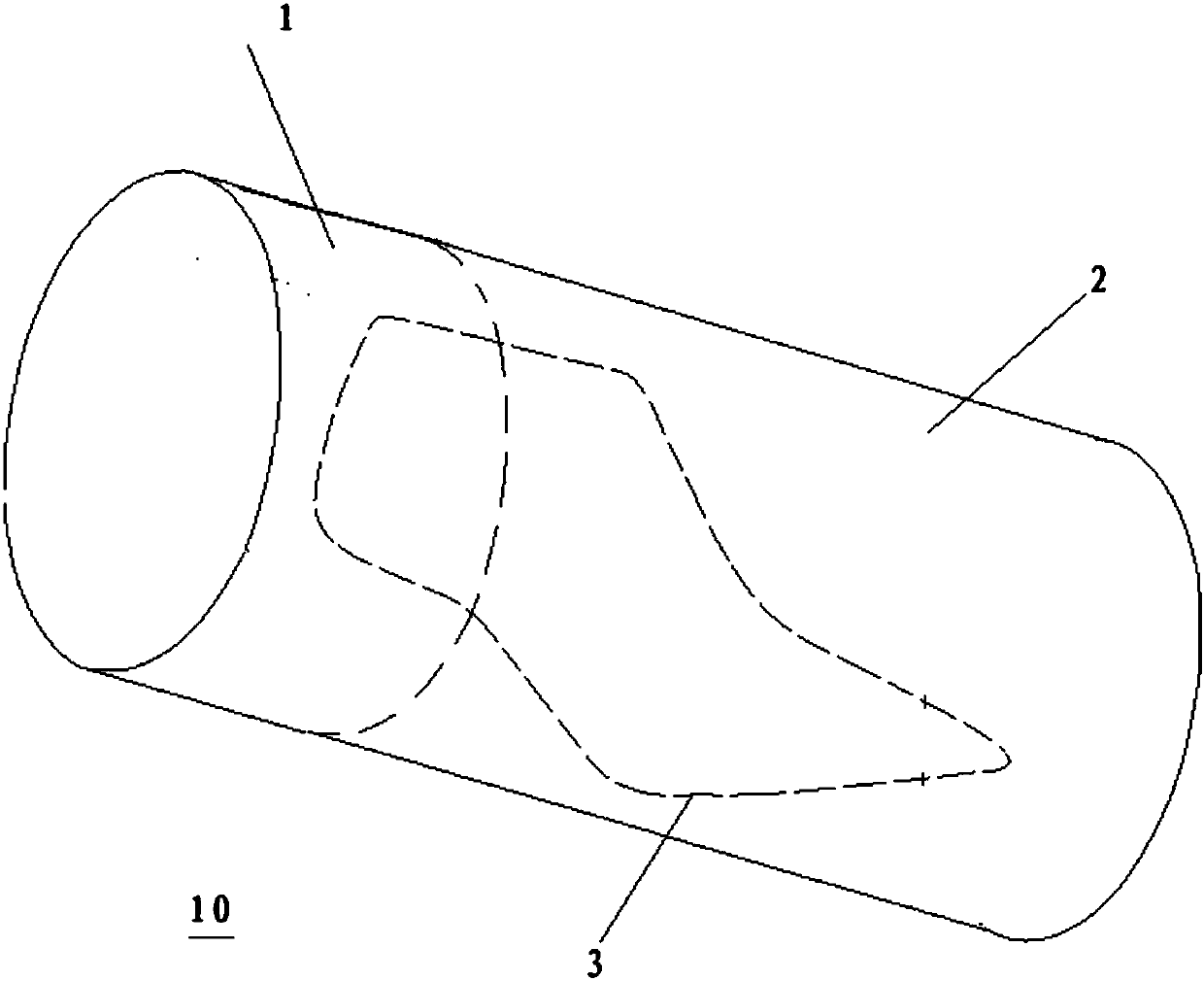

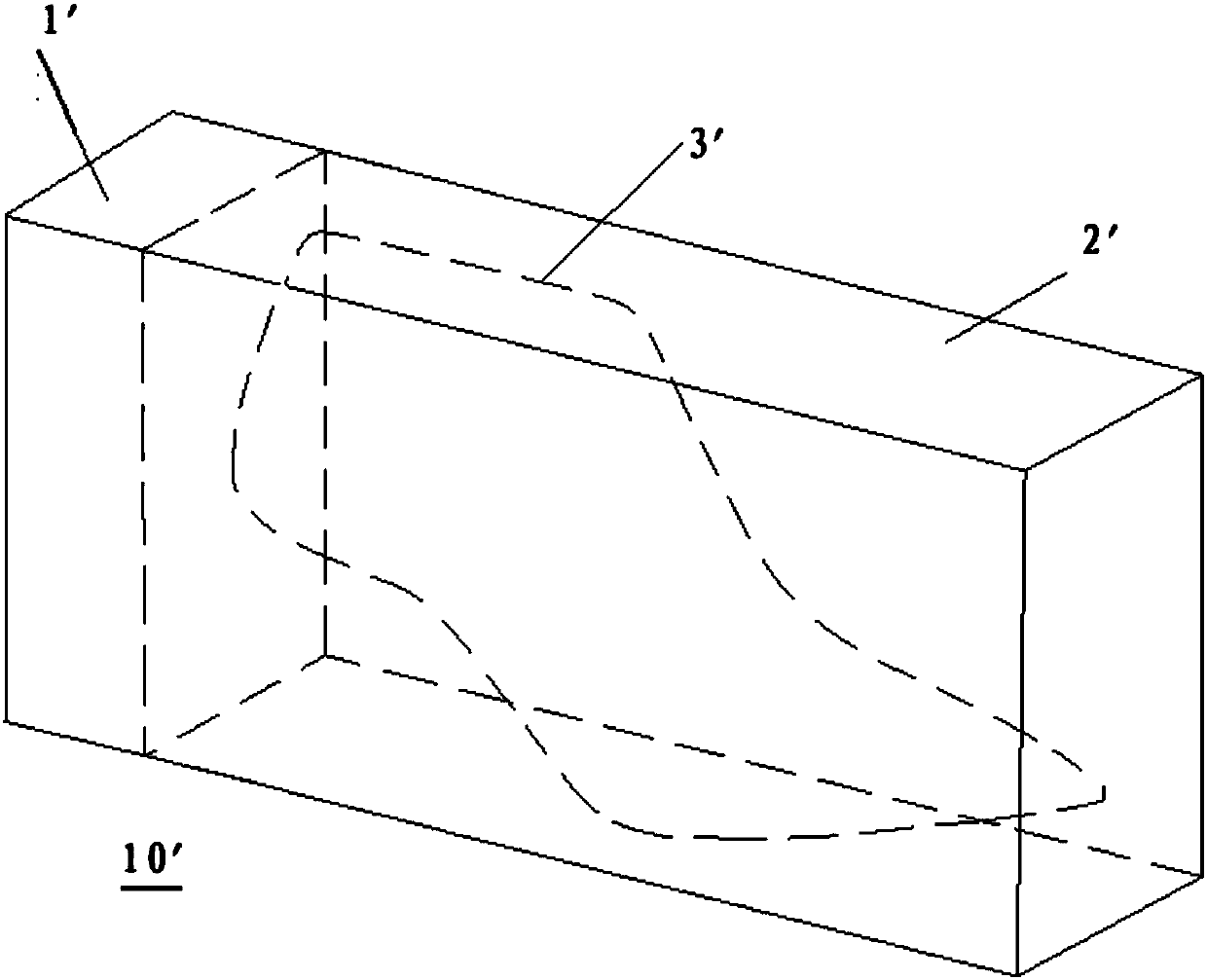

[0046] refer to figure 1 with figure 2 , the rough shoe last blank 10, 10' of the present embodiment comprises a columnar rough shoe last blank body, figure 1 shows a cylindrical, figure 2 Prismatic shapes are shown. The cross-sectional shape on any cross-section of the column is the same, and the cross-sectional shape on any cross-section is centrosymmetric or axisymmetric, and the cross-sectional shape can be rectangle, square, circle, ellipse or polygon.

[0047] The rough body of the shoe last includes integrally formed clamping parts 1, 1' and processing parts 2, 2'.

[0048]The clamping part 1, 1' is used to be clamped when processing the rough body of the shoe last, and the clamping area is preferably located at the end surface of the clamping part ( figure 1 or figure 2 The left end face shown), the clamping method is preferably to clamp and fix the rough body of the shoe last by surrounding the clamping part of the clamping cylinder or square cylinder, and the...

Embodiment 2

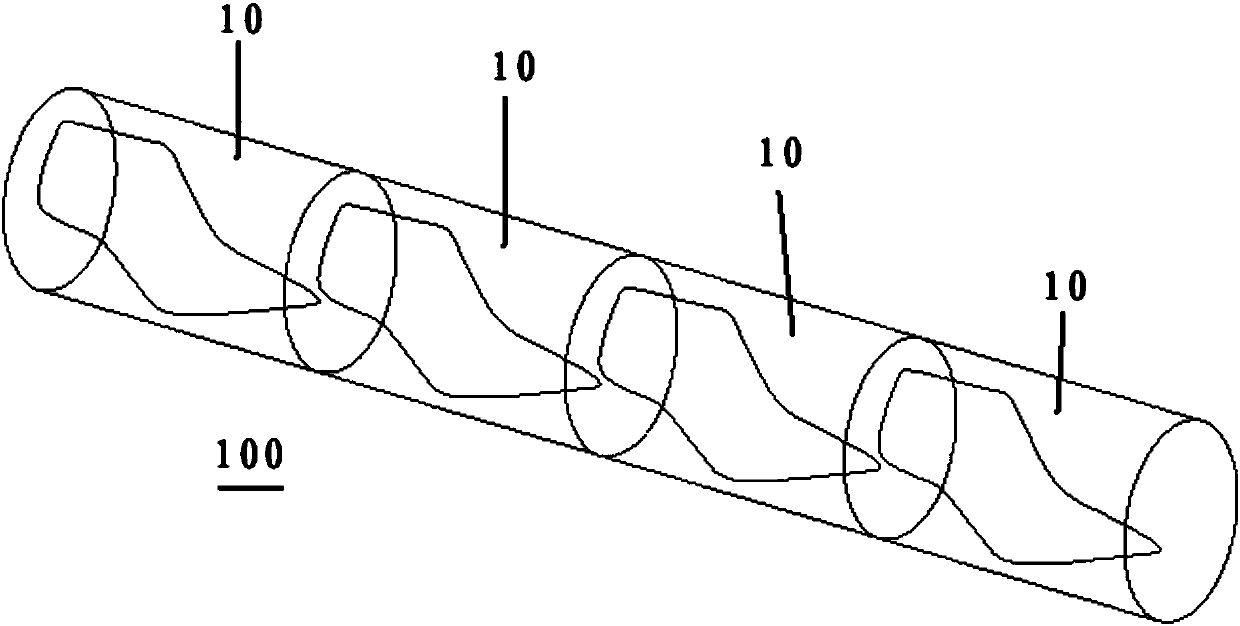

[0062] refer to image 3 with Figure 4 , the shoe last rough billet 100, 100' of this embodiment is an integral strip structure formed by injection molding or extrusion, and can be divided into a plurality of shoe last rough billets 10, 10 in the first embodiment by means of a cutting process. '. The form of the rough billet of the shoe last is convenient for transportation and storage.

[0063] Figure 5 Another cutting method of the shoe last rough billet is shown. It should be pointed out that the rough billet of the shoe last can be combined with image 3 or Figure 4 same, only the cutting method is different. image 3 with Figure 4 cut along a plane perpendicular to the axis, and Figure 5 The shoe last rough billets are cut based on the principle of making full use of materials by using the shape characteristics of the toes and insteps of the rough shoe lasts to be processed. E.g Figure 5 (a) in the manner in which successive parts overlap, and Figure 5 I...

Embodiment 3

[0065] In this embodiment, the method for processing a shoe last by using a shoe last rough blank includes the following steps,

[0066] S1: The last engraving machine clamps and fixes the clamping part, removes most of the margin of the processing part of the rough shoe last, and obtains a semi-finished shoe last, and the semi-finished shoe last includes only connecting the clamping part at the end face of the shoe last cylinder part of the shoe last.

[0067] In detail, step S1 is the rough machining of the rough shoe last, also called rough machining. During rough machining, the clamping part of the rough shoe last is firstly clamped to perform CNC cutting on the processing part.

[0068] After the rough machining, the shoe last rough blank forms a semi-finished shoe last 20 with clamping parts, such as Image 6 shown. The semi-finished shoe last 20 includes a last part 203 connected to the clamping part 201 only at the end face of the mouth of the shoe last, and the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com