Rigid mold-flexible mold composite forming device and method of reducing cylindrical part

A technology for composite forming and cylindrical parts, applied in the field of sheet metal forming, can solve the problems of inability to form rigid molds and low pressure forming efficiency of viscous medium, and achieve the effects of good repeatability of parts, improved forming limit and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

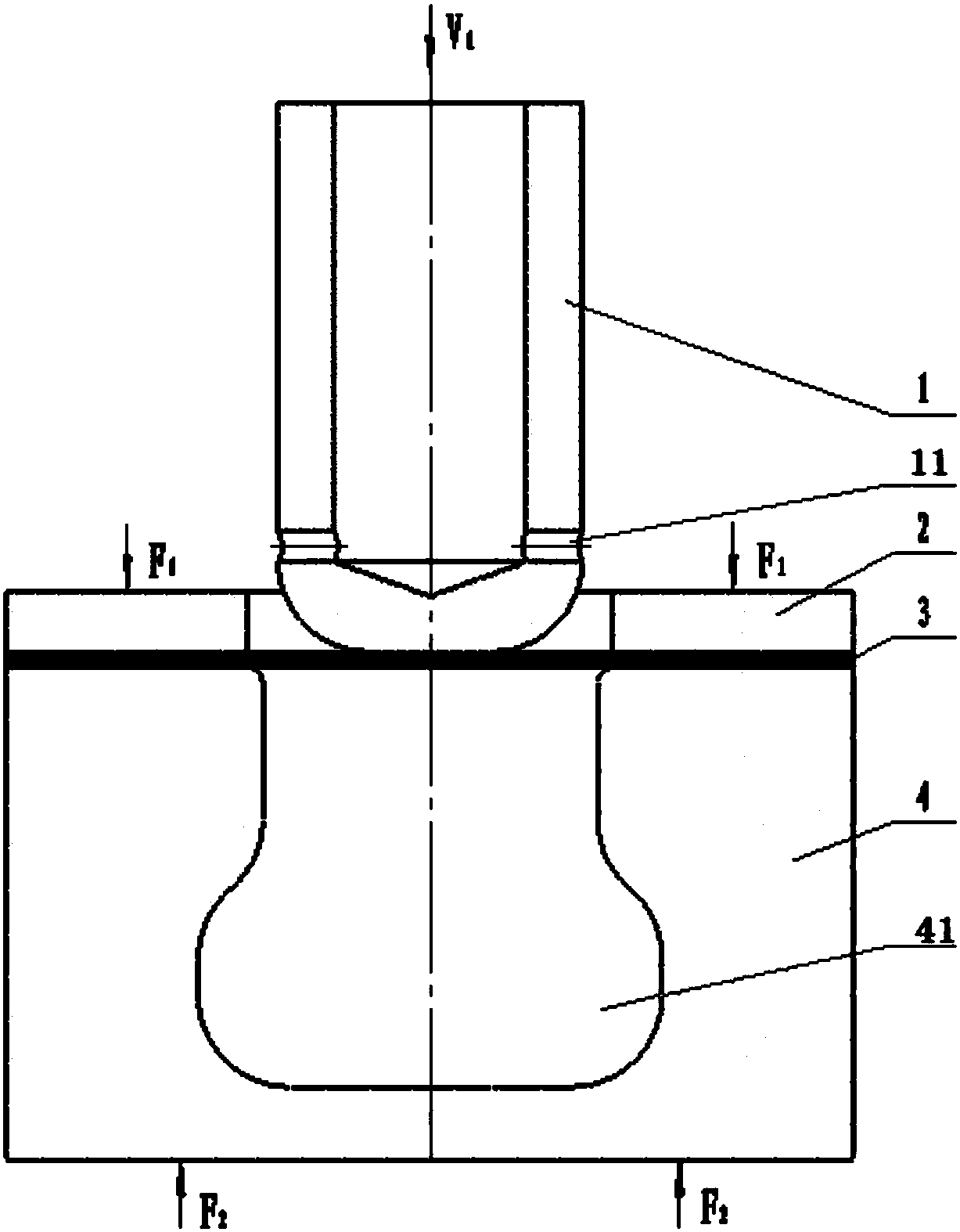

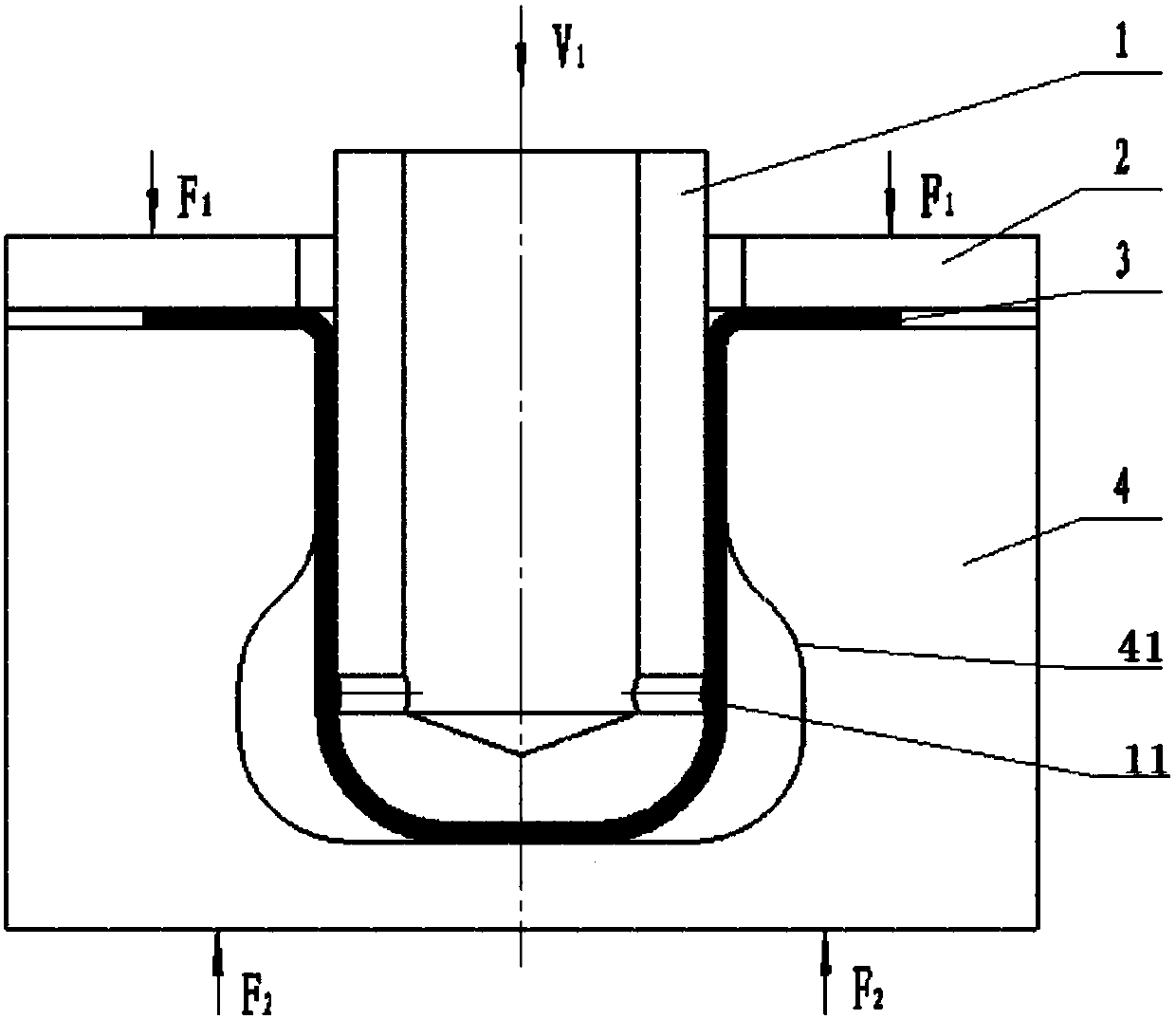

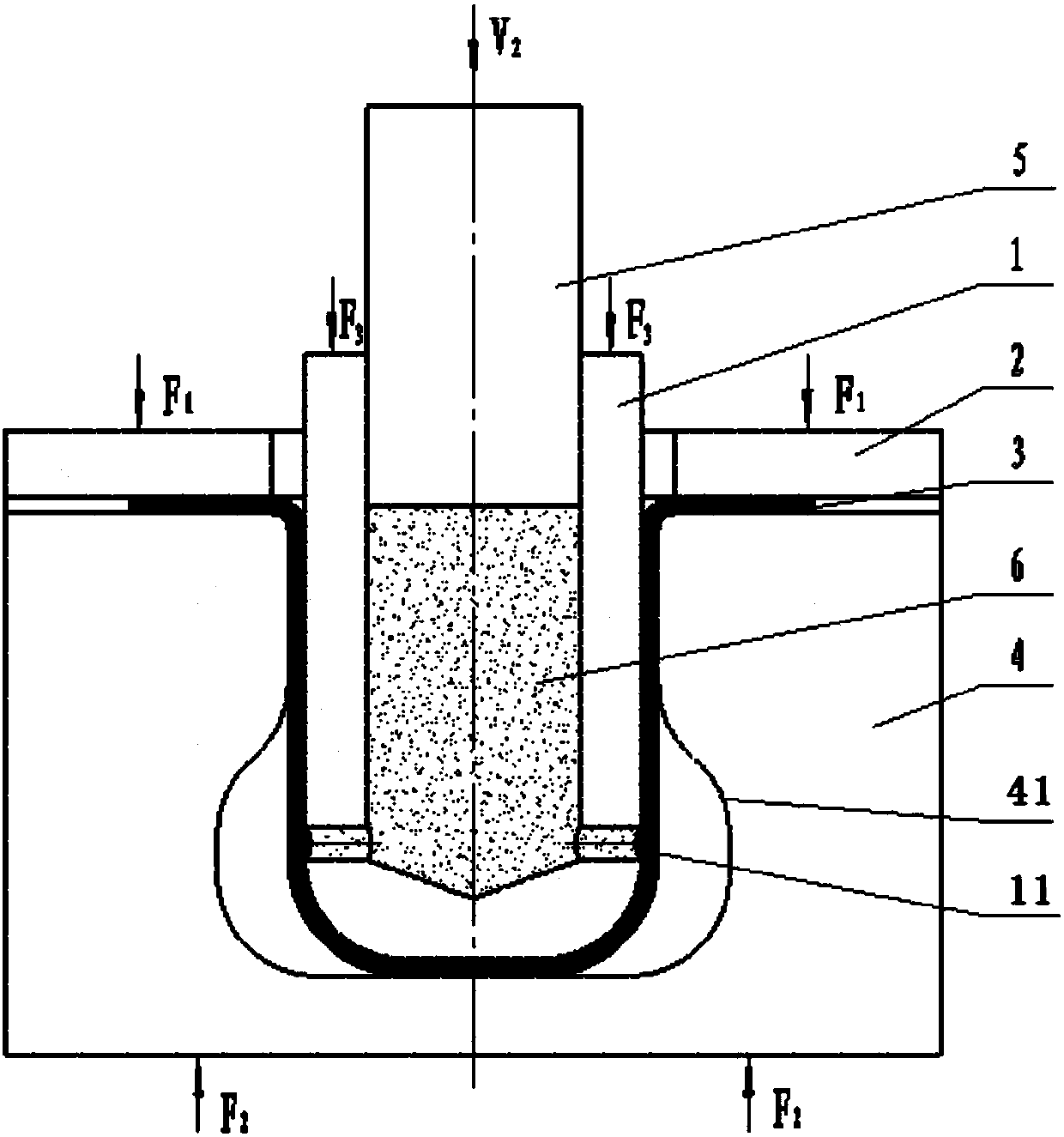

[0027] Such as image 3 As shown, a rigid mold-flexible mold composite forming device for a cylindrical part with reduced diameter includes a first plunger 1, a blank holder 2, a combined die 4 and a second plunger 5; the first plunger 1 has one end Close the open inner cavity at the other end, the closed end of the first plunger 1 is provided with a medium hole 11, the combined die 4 includes two half dies, the two half dies are combined to form a cavity with the same shape as the part to be formed 41. When in use, the blank holder 2 is located above the combined die 4, the blank holder 2 and the combined die 4 are set up and down, and the blank holder 2 and the combined die 4 are provided with a plate 3 to be formed. The closed end of the first plunger 1 extends into the combined concave c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com