Bridge swivel design and construction method in extremely asymmetric state

A construction method and asymmetric technology, applied in the direction of bridge construction, bridges, erection/assembly of bridges, etc., can solve the difference in length, the asymmetry of the swivel beam sections on both sides of the spherical hinge, the swivel bridge without anchoring system, etc. problems to reduce security risks and avoid amplification effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

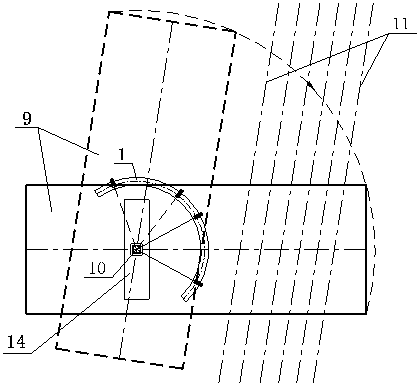

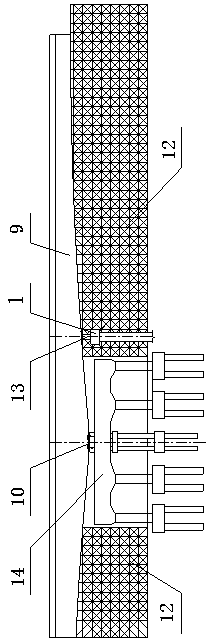

[0041] A bridge adopts a 95+105m swivel steel box girder to cross the iron, and the total width of the bridge deck is 51m. Carry out horizontal swivel construction of unequal span steel box girders, the swivel length is 43.8+91.4m, and the swivel weight is about 8600 tons.

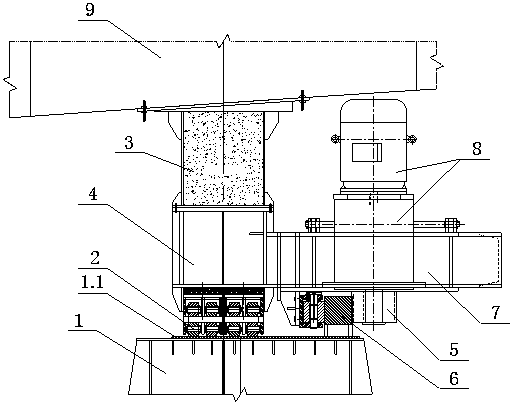

[0042] In order to realize the bridge rotation with extremely asymmetrical span, in addition to arranging the traditional swivel center spherical joint on the top of the pier, an auxiliary support system is installed at the position 23.6m away from the center of the spherical joint at the end of the 91.4m long arm.

[0043] The curved track beam is a steel box structure, which is a steel box with a height of 2m in general, and the beam height in the area passing through the door opening is increased to 3m. Steel pipe columns and concrete pile foundations are set up under the track beam. The out-of-shape track slab is welded to the track beam to form a whole. The roller trolley is supported on the profiled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com