Drilling pretreatment method for cast-in-place pile on block-stone-containing silty soil foundation

A technology of sand foundation and cast-in-situ piles, which is applied to drilling equipment and methods, earthwork drilling, sheet pile walls, etc., can solve the problems of increasing construction period and construction cost, difficulty in ensuring project quality, prolonging working hours, etc., and achieve improvement The effect of project quality and progress, reducing hole collapse, and speeding up the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

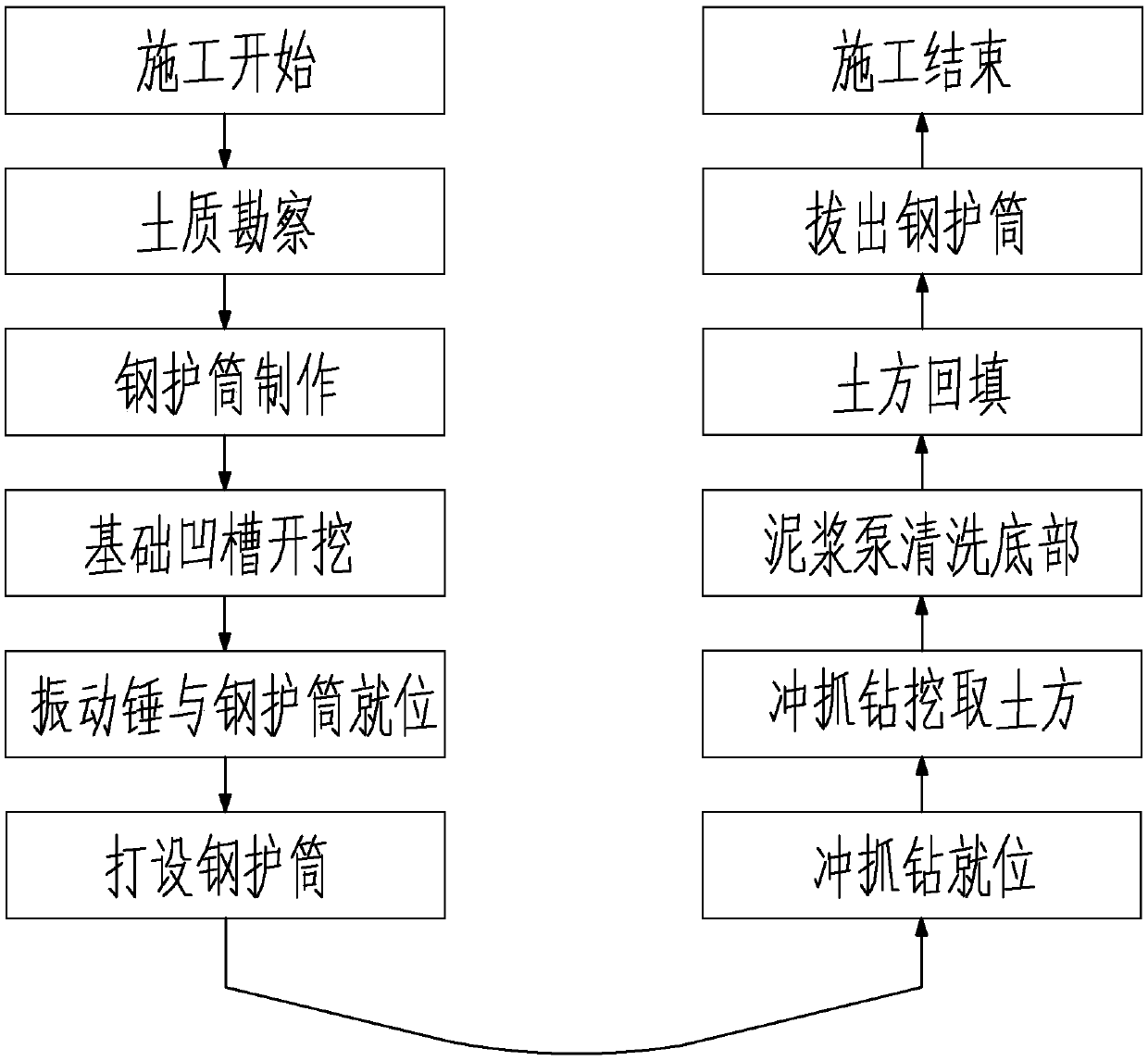

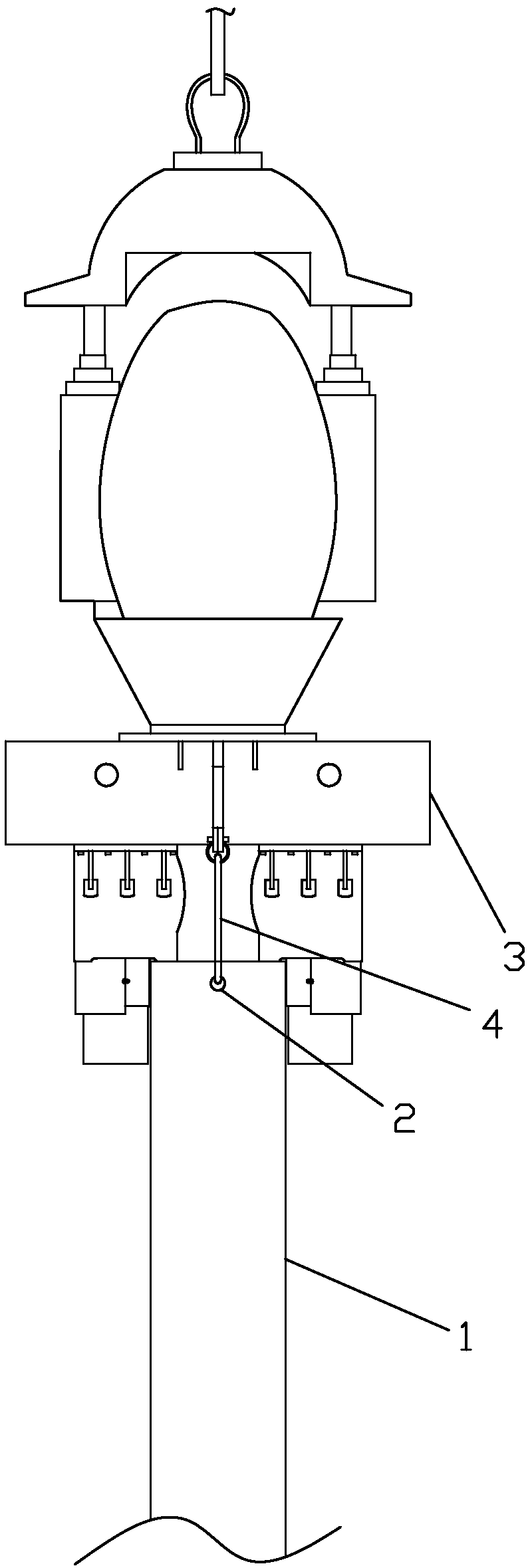

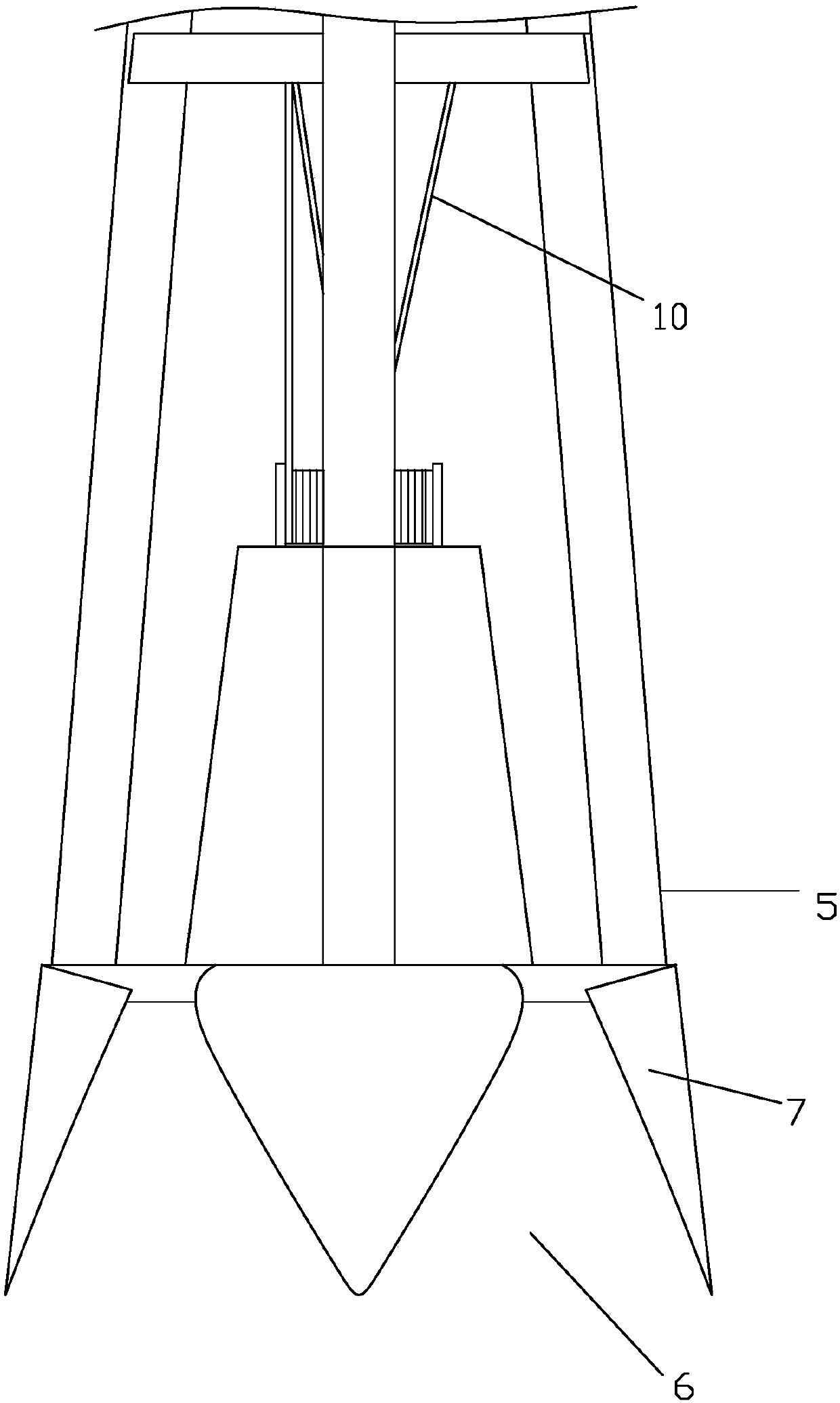

[0035] Such as Figure 1 to Figure 5 Shown, the present invention is the method for pretreatment of borehole drilling of foundation grouting piles containing block stone silt sand, comprising the following steps:

[0036] (1) Soil survey:

[0037] After measuring and setting out, draw the floor plan of the construction site and arrange the drilling positions; collect 100g soil samples at each drilling position, put them in sealed bags after drying, and investigate the soil quality of each soil sample to detect its composition, strength and hardness and other parameters, record the survey data, and determine the structural parameters of the steel casing 1 according to the survey data;

[0038] The soil survey process is used to detect the soil conditions at the drilling location, so that workers can understand the soil structure and properties, so that workers can be equipped with corresponding equipment, tools and other construction preparations according to the soil characte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com