Intensive integral-structure underground sump system and construction method thereof

A technology of integral structure and water tank, applied in drainage, earthwork drilling, safety devices, etc., can solve the problems of large amount of infrastructure works, long construction period, high investment and maintenance costs, and achieve good drainage capacity and small footprint. , The effect of reducing the amount of infrastructure works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

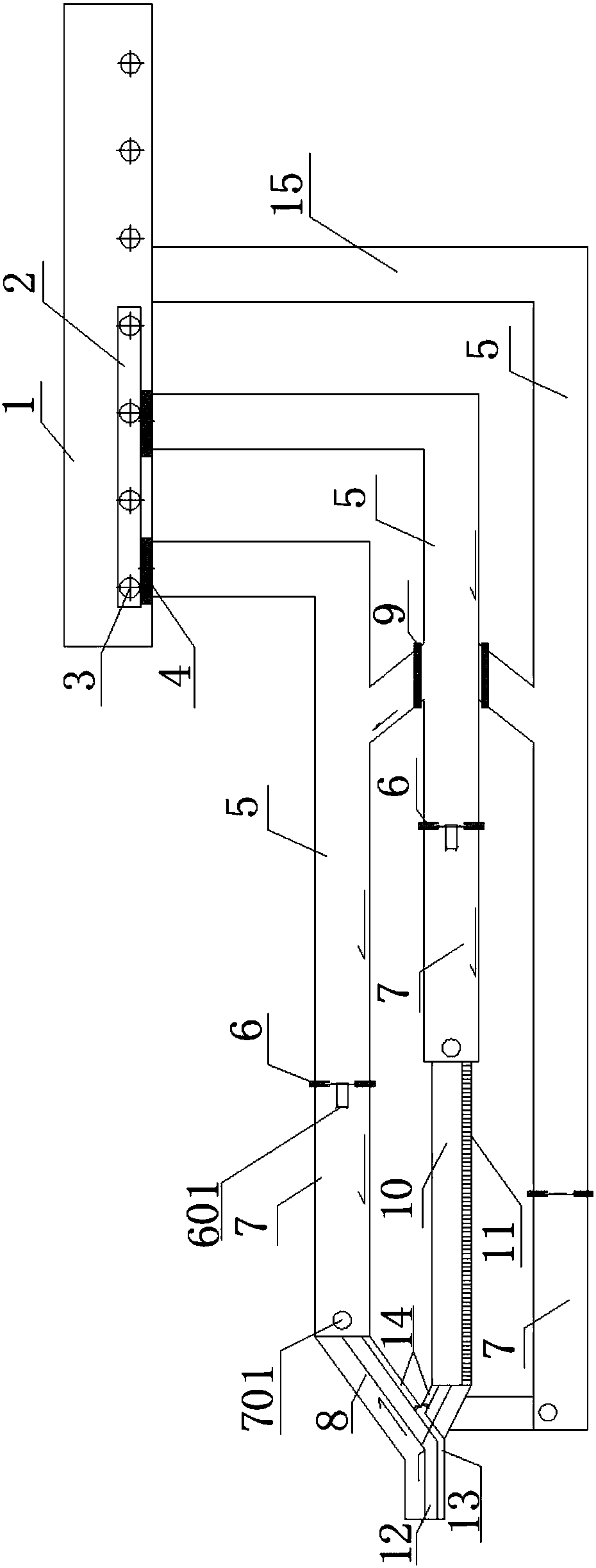

[0033] like figure 1 , 2 As shown, an "intensive integral structure downhole water tank design" of this scheme can effectively solve the problems of large independent structure infrastructure construction, long construction period, and high investment and maintenance costs of the underground water tank sub-item project. perfect solution. According to the safety regulations, the underground water tank must have more than or equal to 2 sets of independent water tanks, sedimentation tanks and several small water distribution wells. In this plan, several sub-projects in the water tank sub-projects are innovatively designed as an overall structure to achieve high-quality, Efficient, economical and convenient practical effects;

[0034] An intensive integral structure underground water tank system, which is provided with a central water pump house 1 and several water tanks 5, the central water pump house 1 is provided with a water distribution lane 2 of the pump house, and several...

Embodiment 2

[0039] Embodiment 2 is basically the same as Embodiment 1, and better, a footstep 11 is provided on the lower hill 10 of the sedimentation tank. It is convenient for personnel to carry out later construction and maintenance.

Embodiment 3

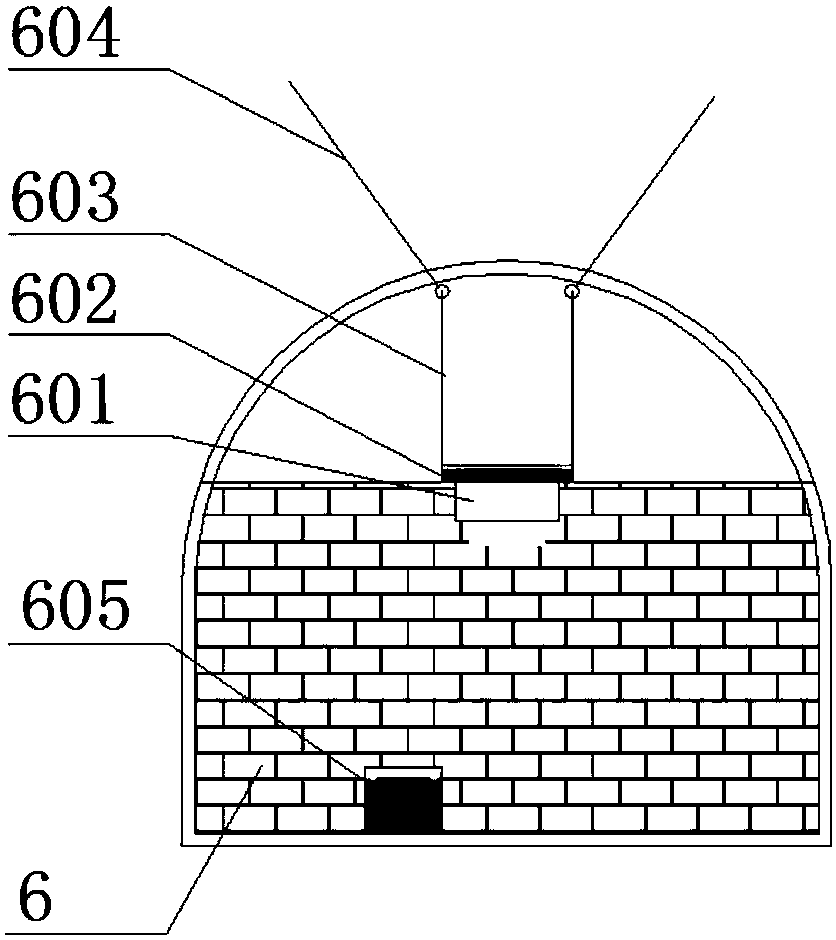

[0041] Embodiment 3 is basically the same as Embodiment 1, and better, the upper part of the semi-sealed overflow curtain wall 6 reinforced concrete is provided with an overflow groove 601 . Satisfying that the overflow of the sedimentation tank 7 directly enters the main water tank 5, it is ensured that the water volume of the sedimentation tank 7 will not exceed the limit, and the safety of the suspension bridge 602 is also guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com