Rear side door assembly for silent box body shell structure

A structural and box-based technology, which is applied to soundproof doors/windows, engine components, machines/engines, etc., can solve the problems of complex processing and assembly, poor firmness and reliability, and low production efficiency, and achieves simple processing technology and good sound insulation effect. , the structure is simple and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

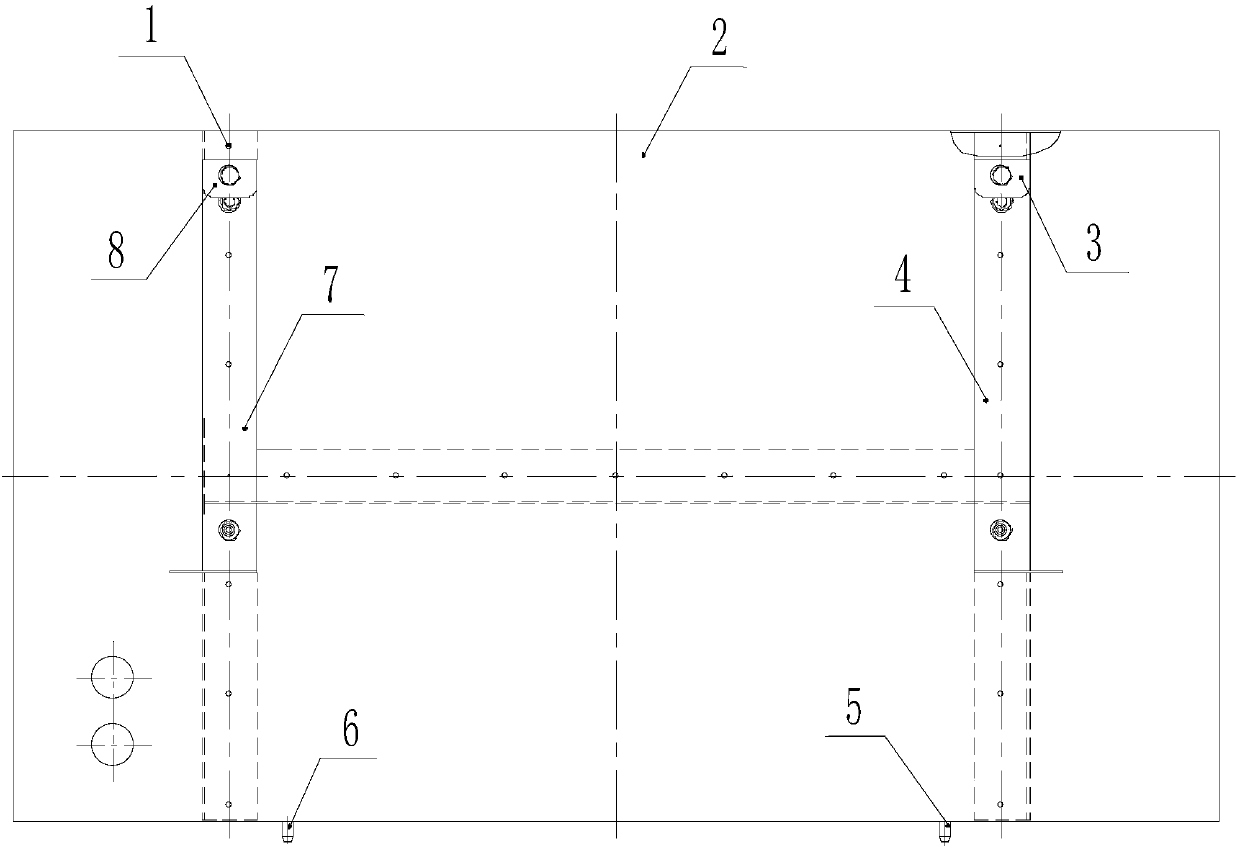

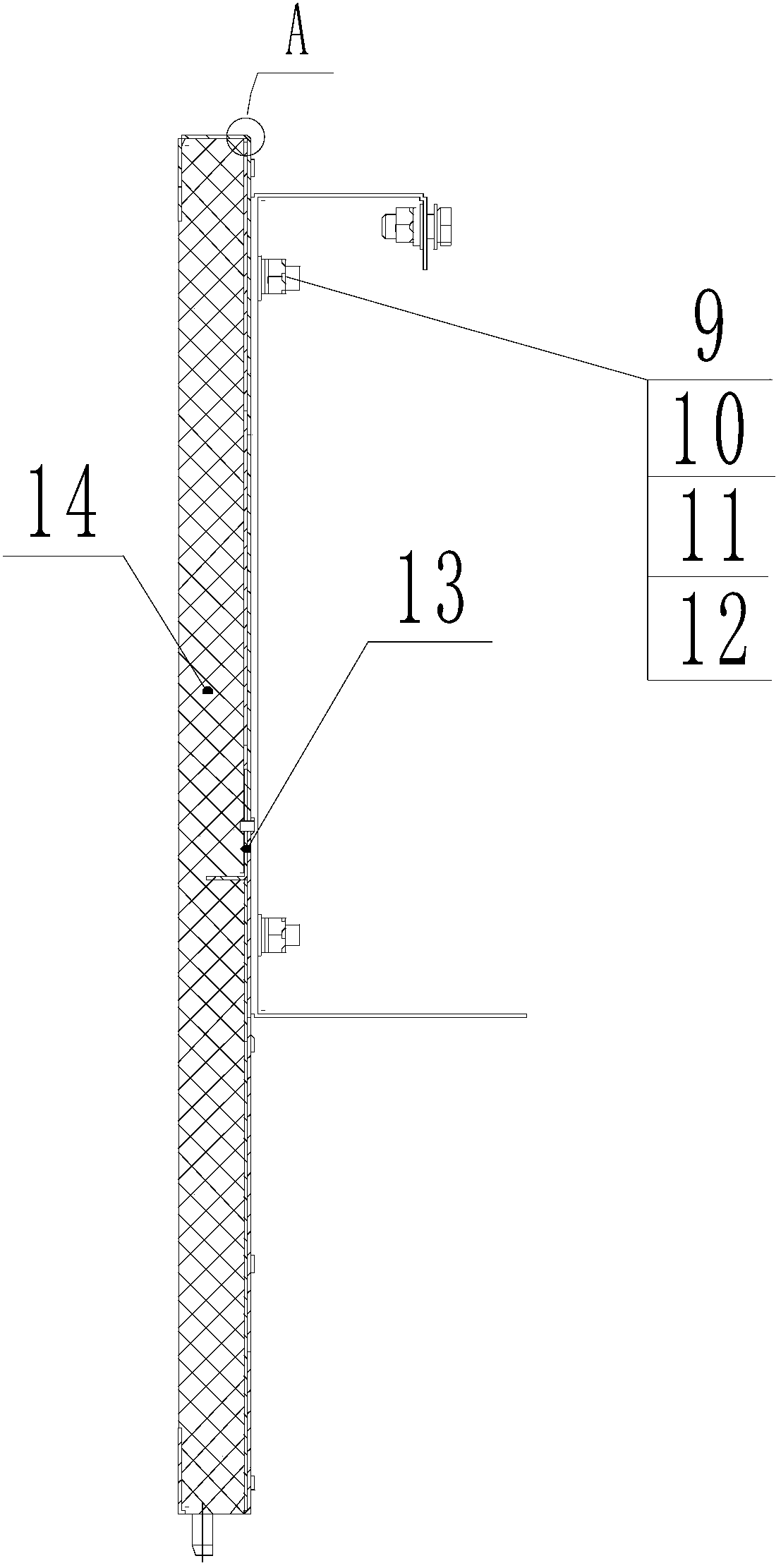

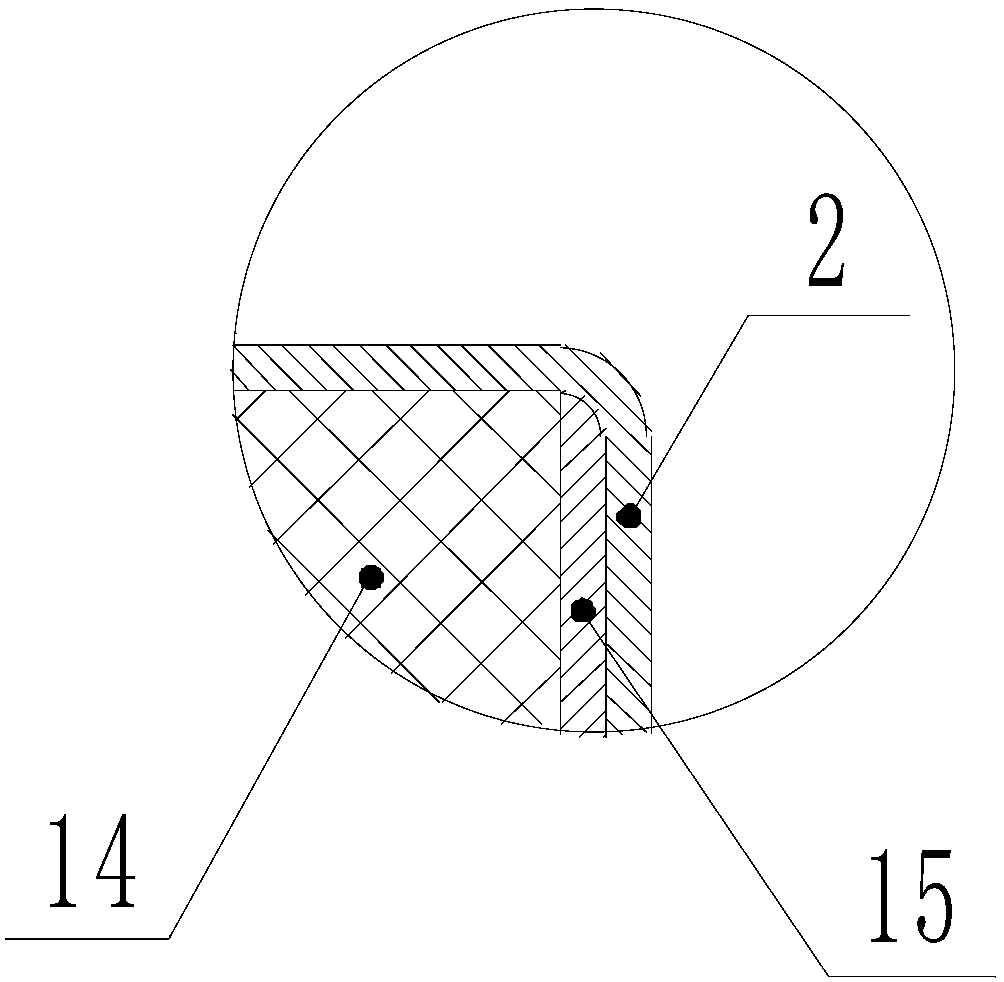

[0019] A rear side door assembly for a silent box shell structure, which includes blind rivets 1, a rear door panel 2, a right water tank bracket 3, a right vertical rib 4, a right positioning pin 5, a left positioning pin 6, and a left vertical rib 7, The left water tank bracket 8, bolts 9, nuts 10, washers 11, spring washers 12, transverse ribs 13, sound-absorbing cotton 14 and damping plates 15, the right vertical ribs 4 and the left vertical ribs 7 are fixedly installed on the rivets 1. On the front end surface of the rear door panel 2, the transverse rib 13 is fixedly installed on the front end surface of the rear door panel 2 through blind rivets 1, the damping plate 15 is fixedly installed in the groove of the rear door panel 2, and the damping plate 15 is connected to the front end surface of the rear door panel 2. The bottom surface...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap