Rubber bearing for circulating pump

A technology of rubber bearings and circulating pumps, which is applied in the field of bearings, can solve the problems of excessive wear and tear, and achieve the effects of improving wear resistance, improving speed and convenience, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

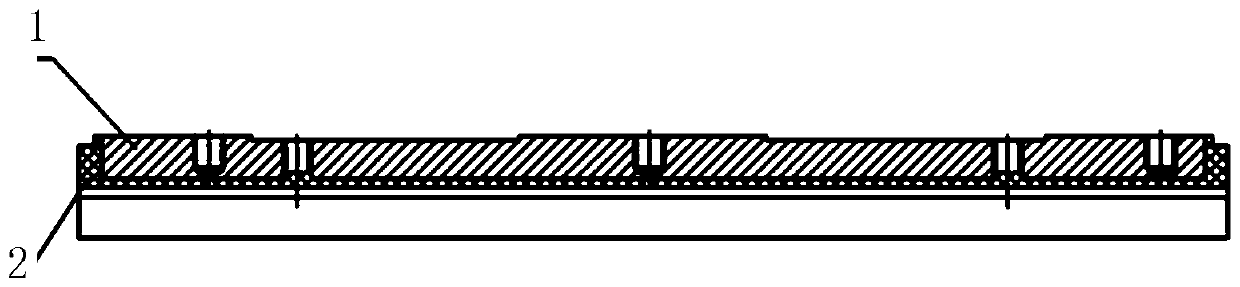

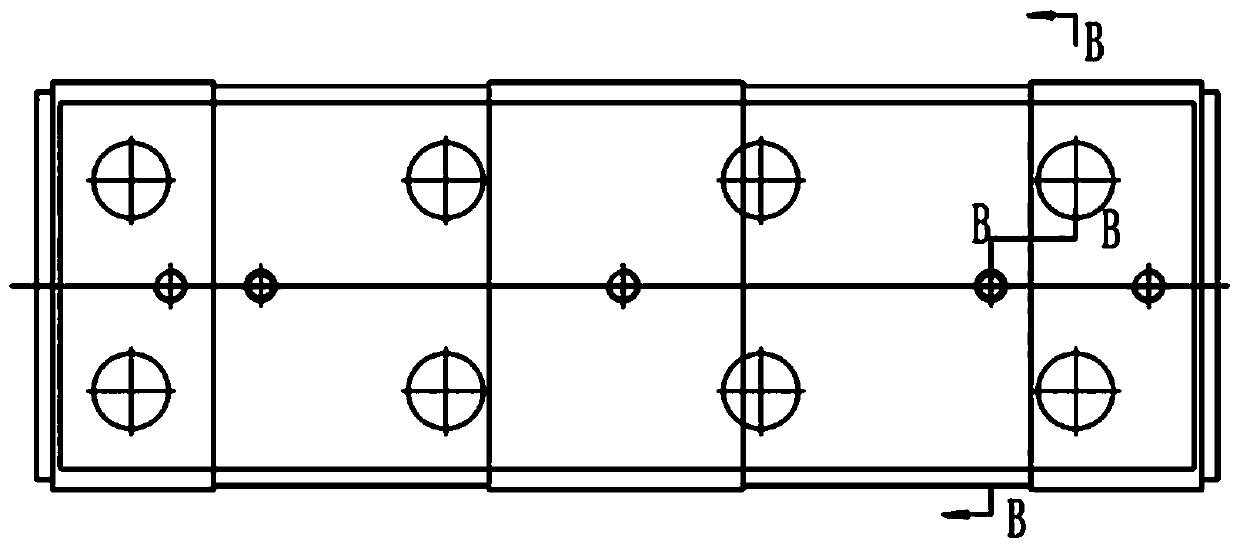

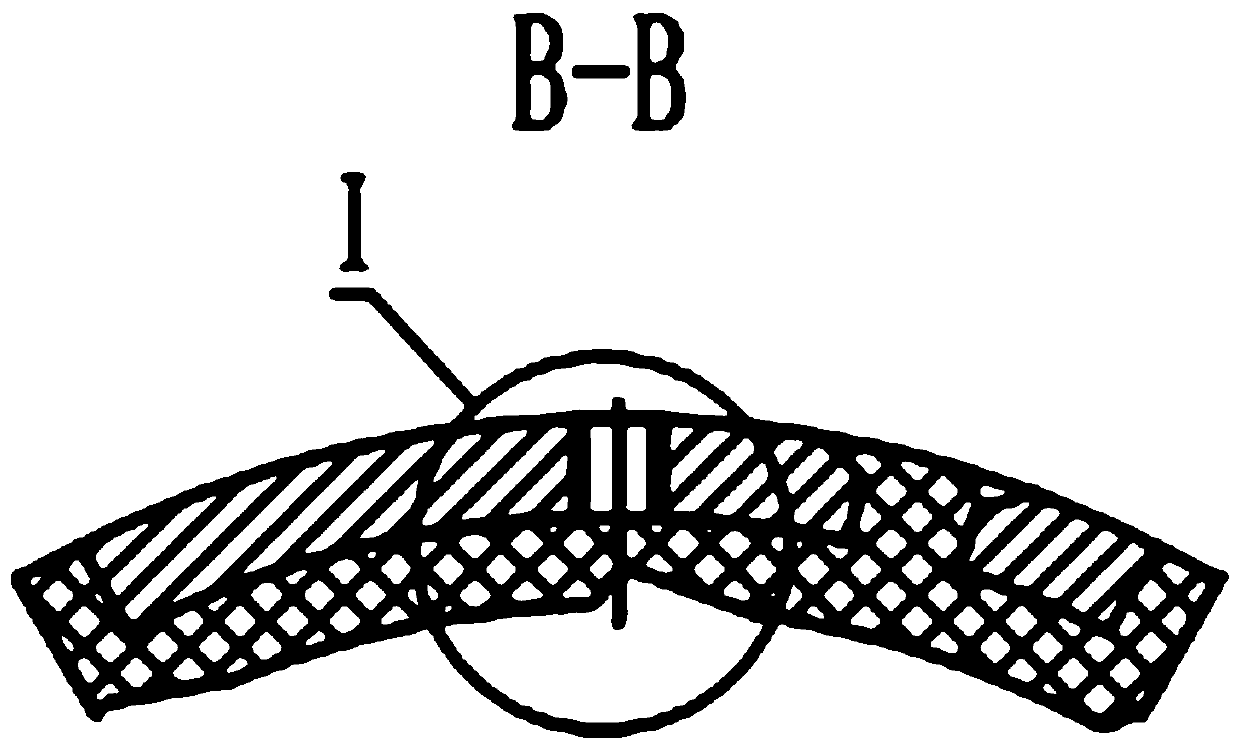

[0024] As shown in the figure, the circulating pump rubber bearing, the bearing body is designed as a split structure. The bearing body is composed of 6-petal strip bearings. The 6-petal strip bearings are evenly arranged. Each strip bearing is installed by fixing bolts and positioning pins. On the corresponding bearing body, each of the described bearings adopts a metal base lining rubber structure. Each bearing is provided with a water passage groove along the axial direction. The shape of the water passing groove is an arc-shaped asymmetric groove.

[0025] The base material of the present invention is 316L, which belongs to austenitic stainless steel, which has good corrosion resistance to various inorganic acids, organic acids, alkalis, and salts, and is a material often selected for seawater as the medium;

[0026] The rubber material is nitrile rubber, which has good chemical resistance, high tensile strength, and excellent physical and processing properties.

[0027] Nitril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com