Vertical shaft-coupling throw searching technique for large-scale water turbine

A technology of hydraulic turbine shaft and process method, which is applied in the direction of adopting mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems of affecting the installation period and manufacturing cost of the unit, affecting the accuracy of finding the pendulum, and the high weight of the coupling, so as to improve the construction site. Shaft accuracy and installation efficiency, reducing equipment requirements, and ensuring the effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

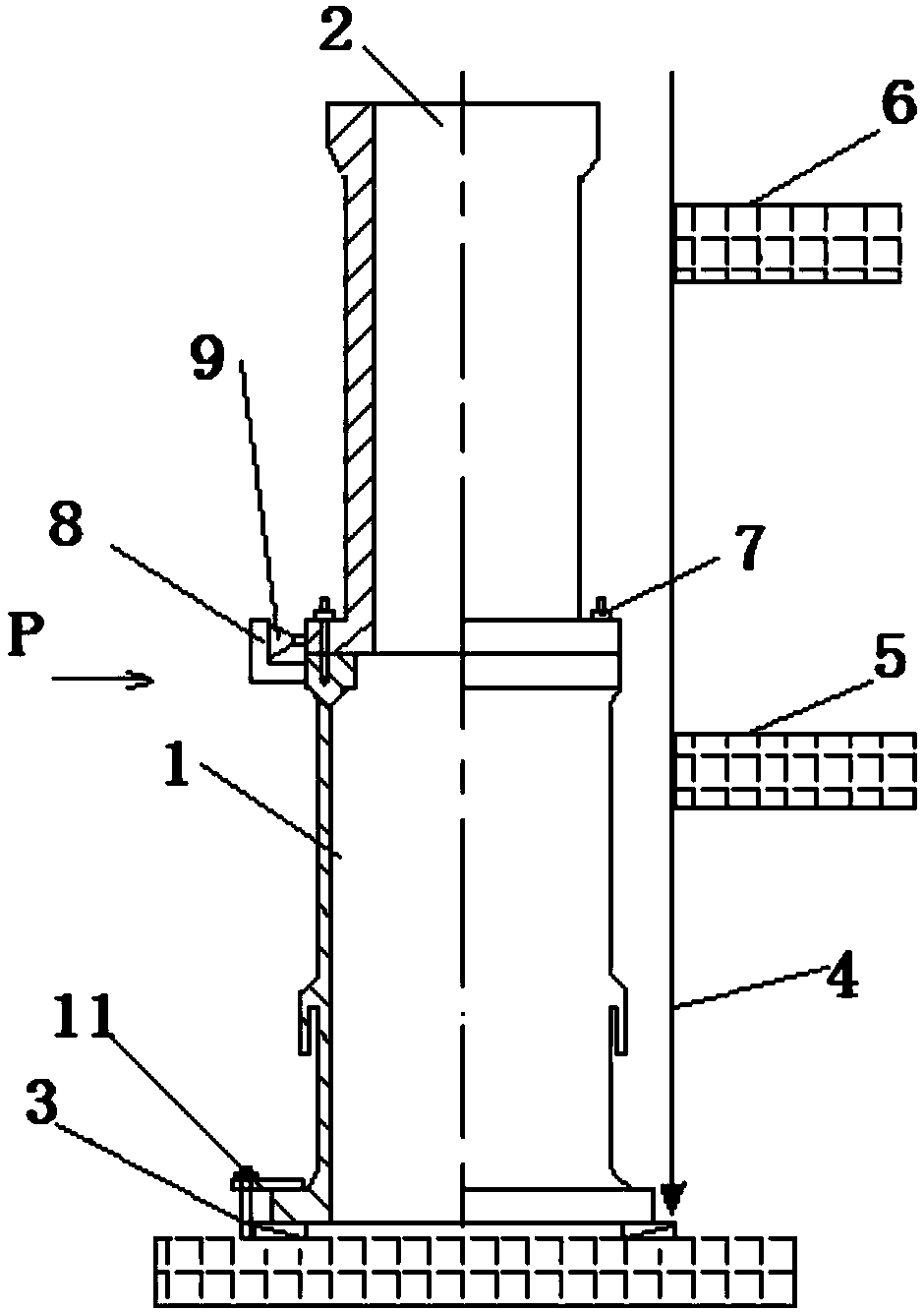

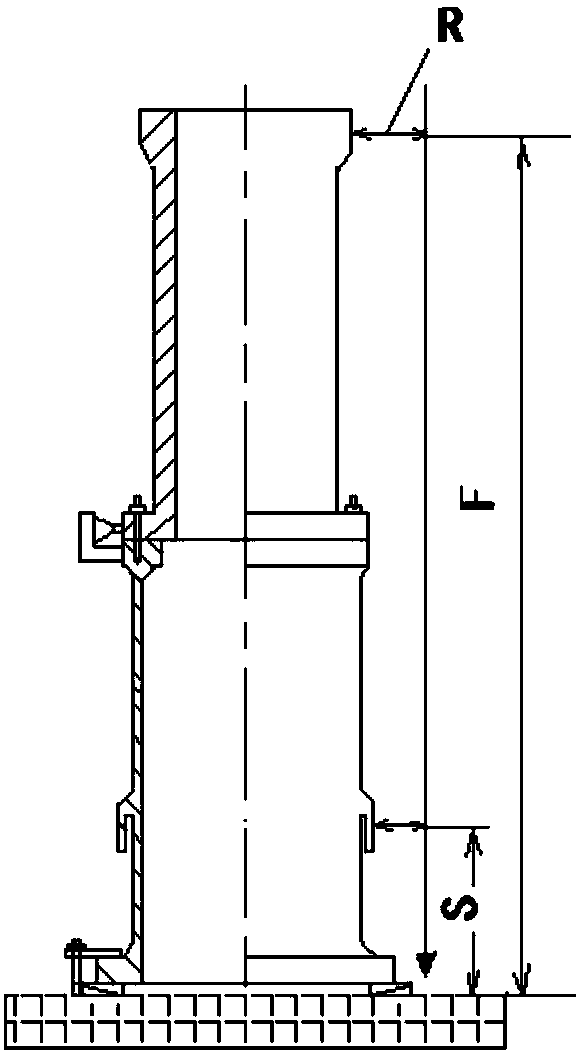

[0046] (1) Lift the turbine shaft 1 vertically and place it on a solid metal platform 12, see figure 1 . Pad the flange surface under the shaft in 4 groups, 2 in each group, a total of 8, and the adjustable shims 3 are evenly distributed, and the copper sheet is placed on the adjustable shims to protect the flange processing surface of the turbine shaft 1;

[0047] (2) Turbine shaft 1 is roughly leveled according to the processing surface on the back side of the flange, and the accuracy is not greater than 0.05mm / 1000mm, and the lower flange is pressed and fixed with the pressure plate and screw assembly 11. Hang the generator shaft 2 on the upper end of the turbine shaft 1. Align the flanges of the turbine shaft 1 and generator shaft 2 according to the finished seams and align the coupling holes, see figure 1 ;

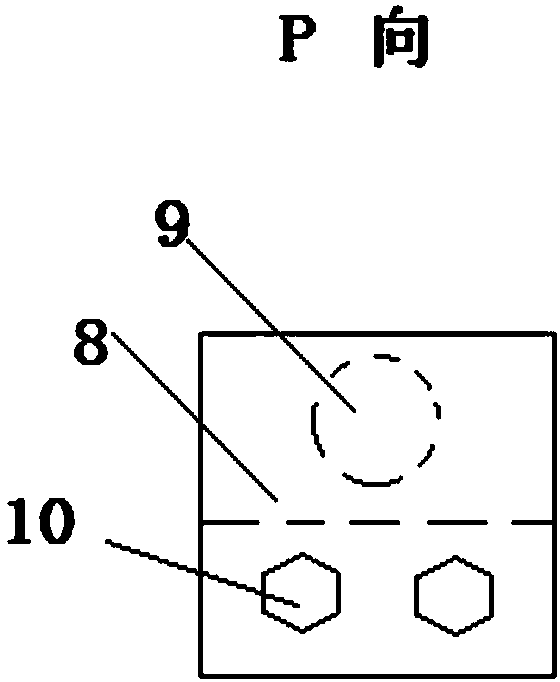

[0048] (3) Build a solid scaffolding platform 5 and platform 6 near the flange surface of the coupling combination and the upper flange surface of the generator s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com