A coke oven temperature measuring robot without repeated start and stop

A robot and coke oven technology, applied in the field of coke oven temperature measurement, can solve problems such as harsh working environment, poor measurement accuracy, and many human factors, and achieve the effects of shortening working hours, improving accuracy, and cleaning air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

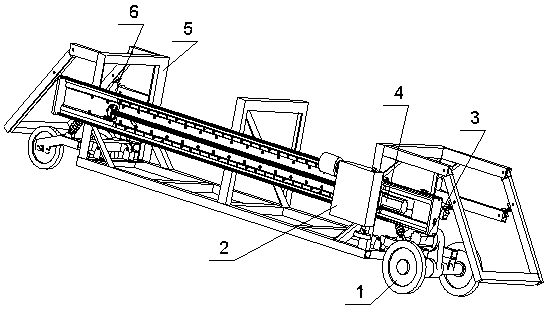

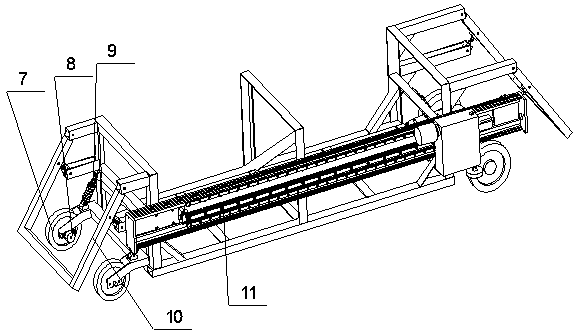

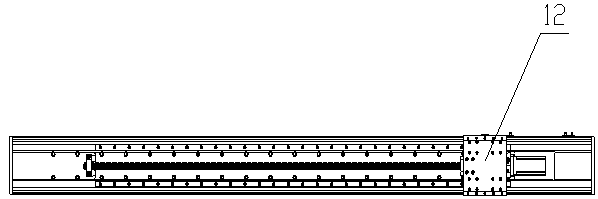

[0045] like figure 1 As shown in ~ 3, a coke oven temperature measuring robot without repeated start and stop includes a carrier part, a mobile temperature measuring part and a power and detection part, and is characterized in that the carrier part consists of an anti-collision device 10, a shock absorber 9 and a carrier The frame is composed of 5; the mobile temperature measurement part is composed of a ball screw pair 11, a workbench 12, a servo motor 4 and a cover temperature measurement device 2, the whole part is installed on the side of the carrier frame, and the cover temperature measurement device is installed on the ball On the workbench on the screw pair, the position of the workbench is controlled by controlling the rotation of the servo motor, so that the temperature measuring device for lifting the cover can accurately complete a series of temperature measurement actions; the power and detection part is composed of a power servo motor 3 Rail car rear axle 1, drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com