Denitration device and denitration method

A technology of denitrification and denitrification rate, applied in the field of denitrification devices, can solve the problems of increased heating costs, increased operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

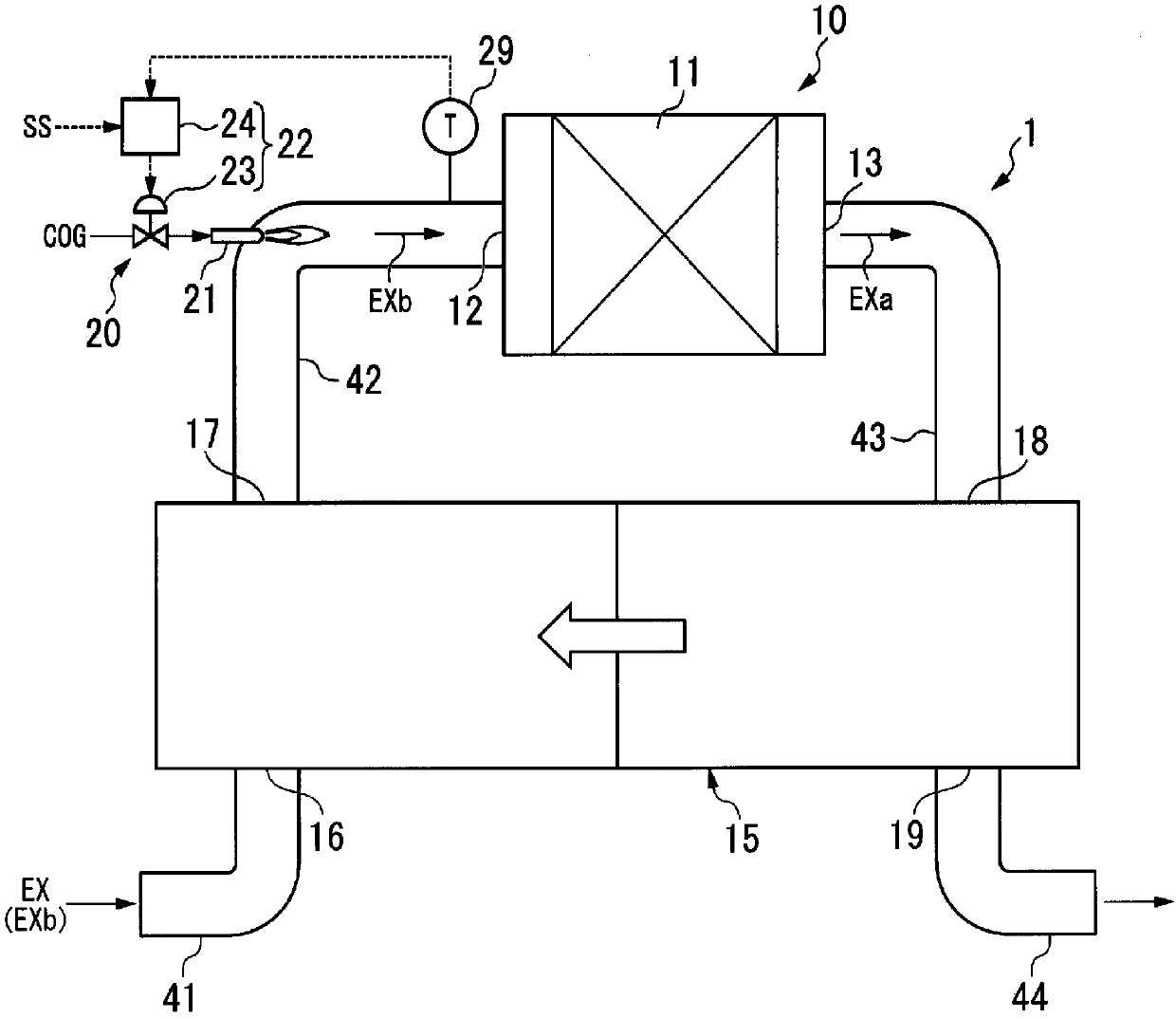

[0107] refer to Figure 1 ~ Figure 3 A first embodiment of the denitration device of the present invention will be described.

[0108] Nitrogen oxides (hereinafter referred to as NOx), CO, and the like are contained in the exhaust gas treated by the denitration device of the present embodiment.

[0109] Such as figure 1 As shown, the denitration device 1 of the present embodiment includes a denitration reactor 10 , a heat exchanger 15 , a heater 20 and a thermometer 29 . The denitration reactor 10 reduces NOx contained in the exhaust gas EX. The heat exchanger 15 exchanges heat between the exhaust gas EX before flowing into the denitration reactor 10 , that is, the pre-denitration gas EXb, and the exhaust gas EX that flows out of the denitration reactor 10 , that is, the denitration completed gas EXa. The heater 20 heats the exhaust gas EX. The thermometer 29 detects the temperature of the exhaust gas EX.

[0110] A reaction container of the denitration reactor 10 is fill...

no. 4 approach

[0232] refer to Figure 12 and Figure 13A fourth embodiment of the denitration device of the present invention will be described.

[0233] Such as Figure 12 As shown, the denitration device 1c of the present embodiment is a modified example of the denitration device 1a of the second embodiment. The denitrification device 1c of this embodiment adds a bypass line 45, a bypass flow rate regulator 46, and a bypass waste heat recovery device 35c to the denitrification device 1a of the second embodiment, and omits the denitrification device 1a of the second embodiment. Waste heat recovery device 35.

[0234] The bypass line 45 connects the first denitrated gas line 43 and the second denitrated gas line 44 , and makes the denitrated gas EXa bypass the heat exchanger 15 .

[0235] The bypass flow rate regulator 46 includes a bypass valve 47 and a bypass controller 48 . The bypass valve 47 is provided in the bypass line 45 and adjusts the flow rate of the denitrated gas EXa flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com