Forming machine of bean curd sheets

A molding machine and louver skin technology, applied in cheese substitutes, dairy products, applications, etc., can solve the problems of low production efficiency, heavy workload, high labor cost, etc., and achieve the effect of stable operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

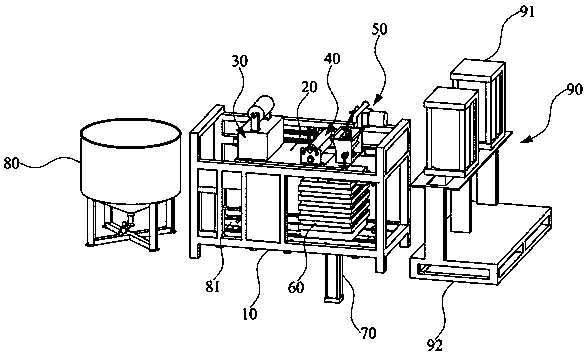

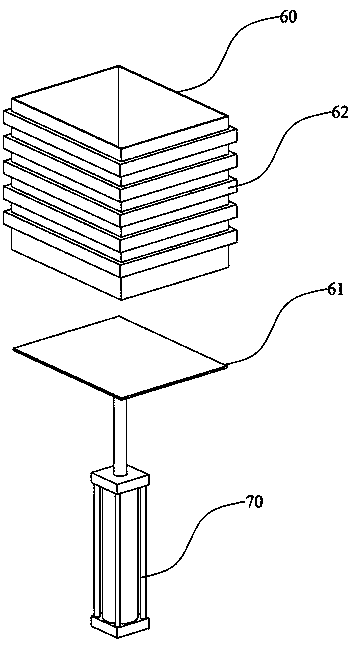

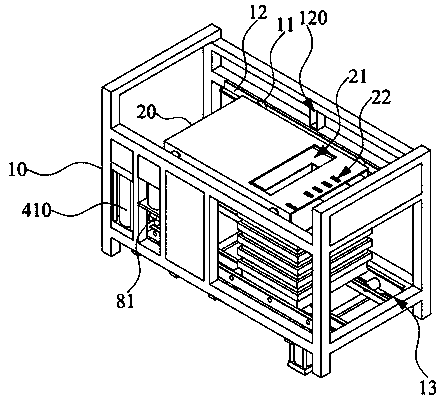

[0029] Please also refer to figure 1 and figure 2 , figure 1 It is a perspective view of the louver skin forming machine of the embodiment of the present application; figure 2 It is a schematic diagram of the receiving box 60 of the embodiment of the present application. As shown in the figure, a louver skin forming machine includes a frame 10; a movable platform 20 installed on the frame 10; a transmission assembly 30, a conveying assembly 40 and a blanking assembly 50 arranged on the movable platform 20; located under the movable platform 20 The material receiving box 60, the bottom plate 61 of the material receiving box 60 is driven up and down by th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap