Mango peeler

A peeling machine and mango technology, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve problems such as hidden safety hazards, and achieve the effect of improving efficiency and ensuring the integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

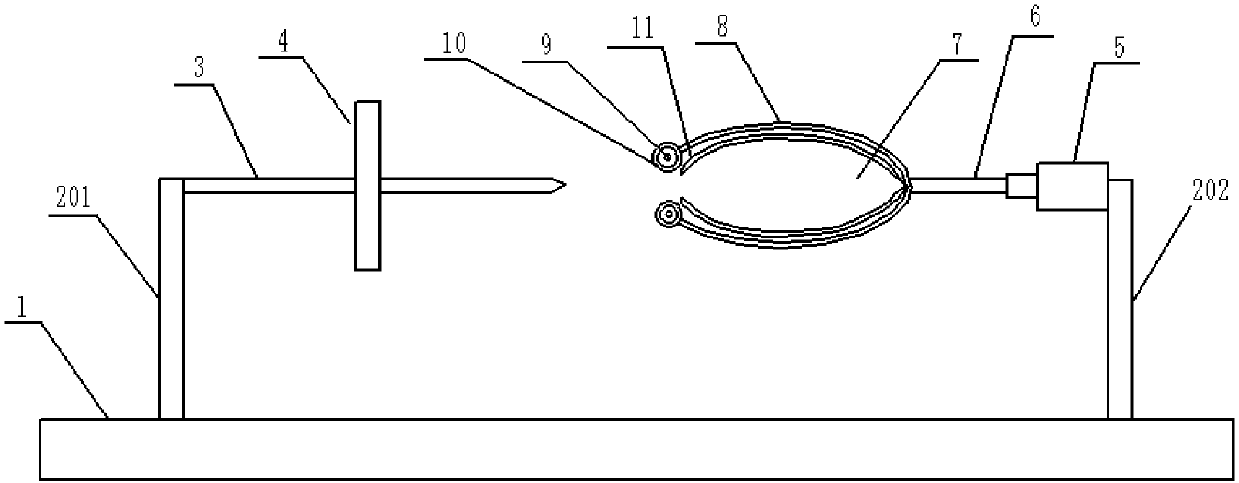

[0017] Embodiment one is basically as attached figure 1 Shown:

[0018] The mango peeling machine includes a base 1 and a first support 201 and a second support 202 that are relatively arranged on the base 1. The first support 201 is provided with a pintle 3, and the middle part of the pintle 3 is provided with a baffle 4; the second support 202 is provided with a telescopic mechanism 5, the telescopic end of the telescopic mechanism 5 is provided with a shaft 6 at the same horizontal position as the needle 3, the end of the shaft 6 is provided with a spindle-shaped claw 7, and the claw 7 includes two An elastic strip 8, one end of the claw portion 7 is connected to the end of the shaft 6, and the other end is provided with a hob 9, the hob 9 is composed of a cylinder and a knife edge 10 surrounding the cylinder, and the cylinder and the shaft The rod 6 is vertical; the claw 7 is provided with an elastic blade 11 corresponding to the elastic strip 8, the elastic blade 11 is l...

Embodiment 2

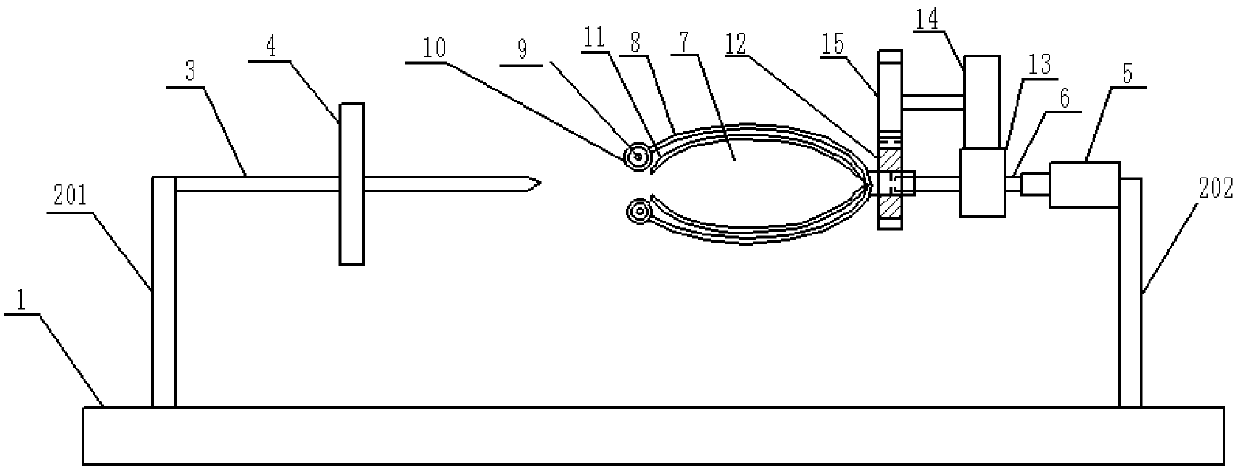

[0020] Embodiment two is basically as attached figure 2 Shown:

[0021] Mango peeling machine, the difference between this embodiment and the first embodiment is that the claw part 7 and the shaft rod 6 are in rotational connection, a driven gear 12 is provided between the claw part 7 and the shaft rod 6, and the shaft rod 6 is close to the driven gear One end of 12 is equipped with base 13, and base 13 is provided with motor 14, and the output end of motor 14 is provided with driving gear 15, and driven gear 12 is meshed with driving gear 15.

[0022] The mango peeling machine of this embodiment is basically the same as the mango peeling machine in Embodiment 1, the difference is that when the end of the claw 7 reaches the baffle plate 4 to complete the peeling and peeling, the mango peeling machine on the base 13 The fixed motor 14 starts, and now the driving gear 15 rotates to drive the driven gear 12 to rotate. Since the claw 7 is connected to the driven gear 12 and is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com