Pain relieving ointment and production technology thereof

A production process and ointment technology, applied in the field of medicine, can solve the problems that the ointment cannot be reused, the air permeability of the ointment is not good, the waterproofness is not good, and the effects of promoting microcirculation, good compliance and good waterproofness are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

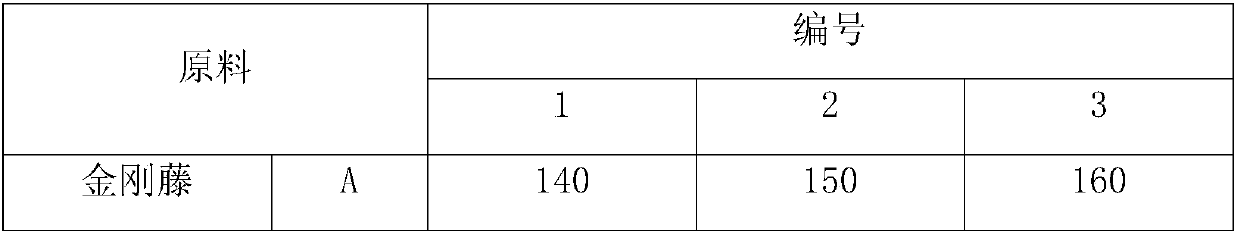

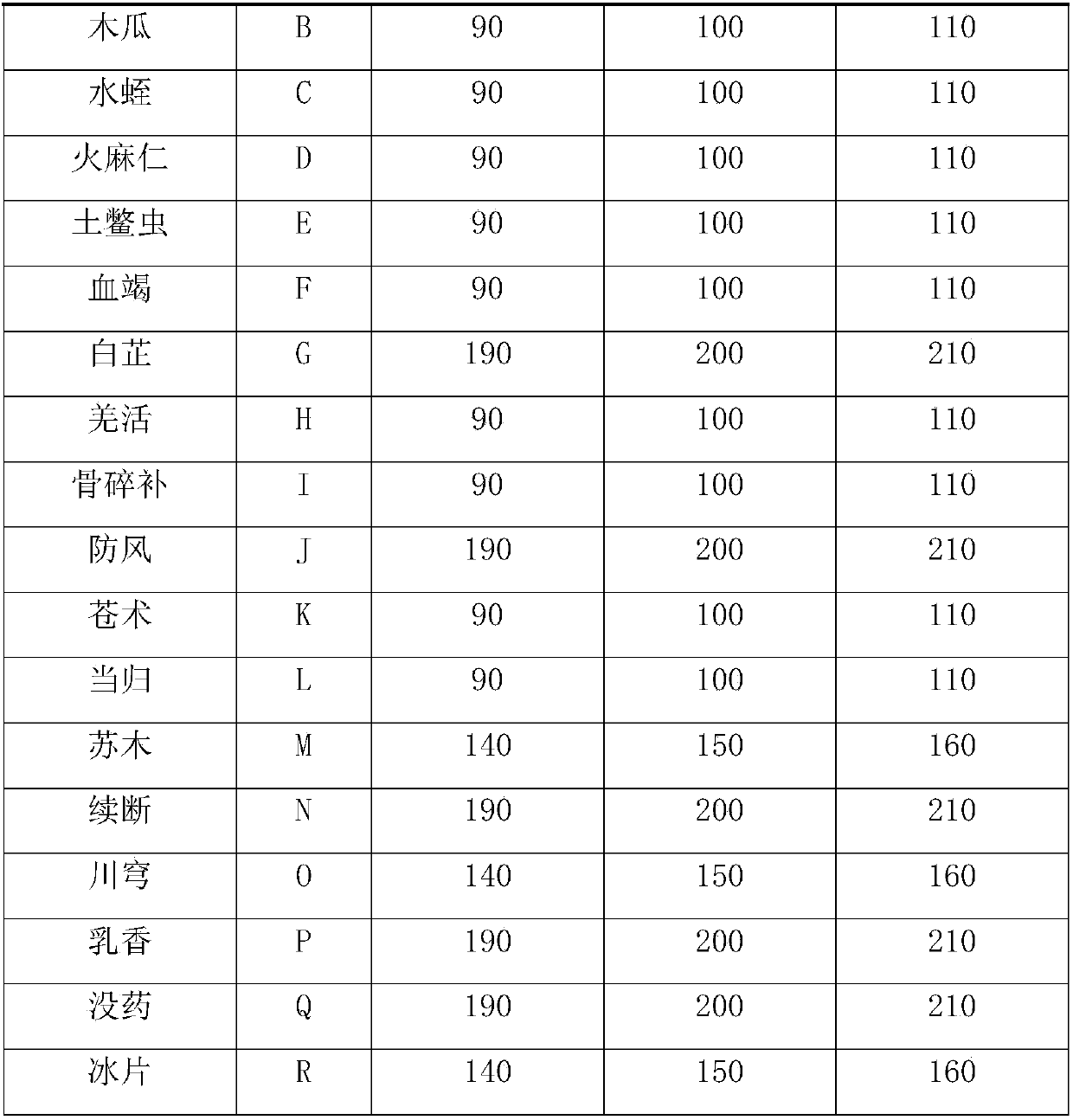

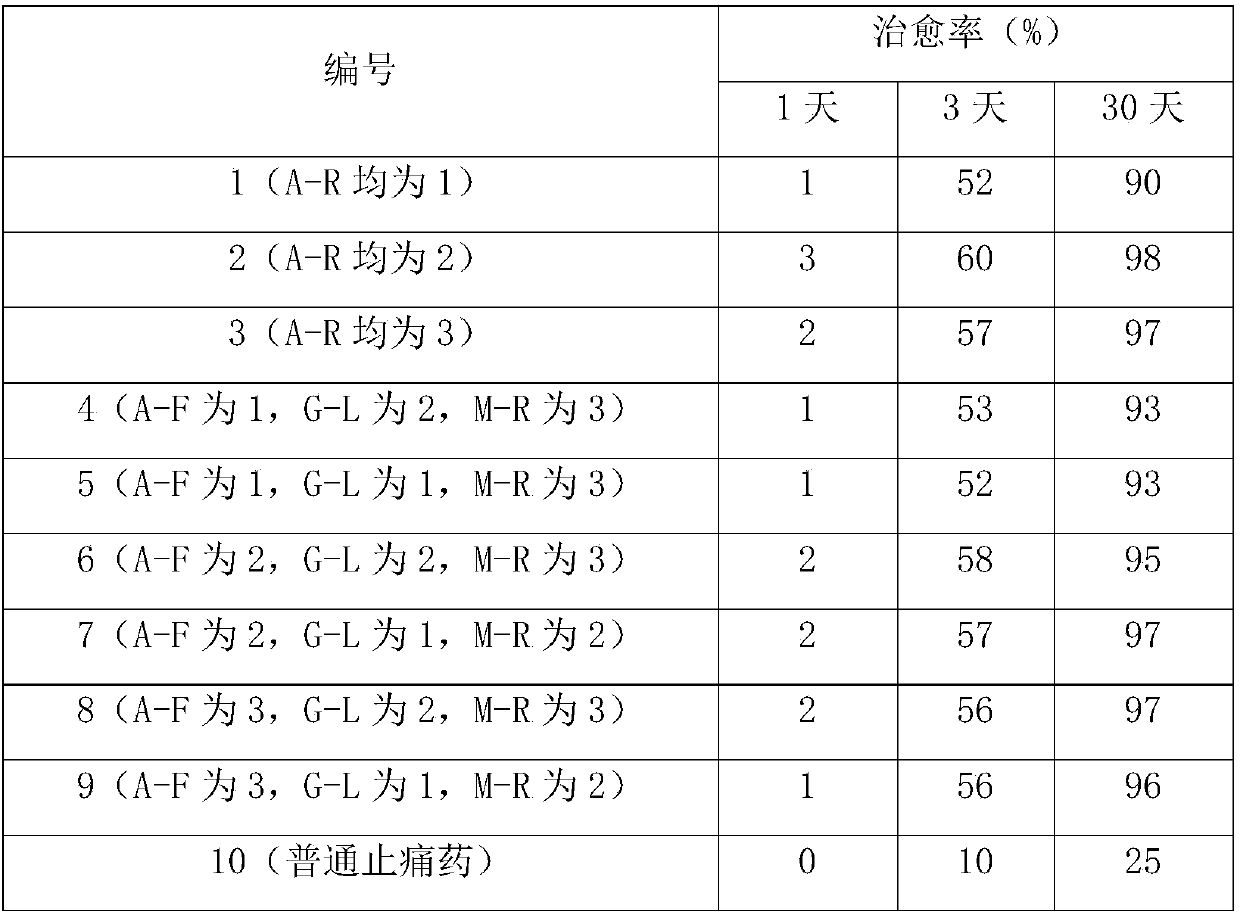

Embodiment 1

[0060] A pain-dispelling ointment and a production process thereof, the production process comprising:

[0061] (1) Preparation of traditional Chinese medicine extract

[0062] The formula of the traditional Chinese medicine extract is as follows: 140 parts of Vajra vine, 90 parts of papaya, 90 parts of leech, 90 parts of hemp seed, 90 parts of ground beetle, 90 parts of dried blood, 190 parts of Angelica dahurica, 90 parts of notopterygium, 90 parts of drynaria, 190 parts of Fangfeng, 90 parts of Cangzhu, 90 parts of Angelica, 140 parts of Sappan, 190 parts of Dipsacus, 140 parts of Chuanqiong, 190 parts of frankincense, 190 parts of myrrh, and 140 parts of borneol;

[0063] After mixing the above raw materials, wash and grind them, then soak in hot water for 2 hours at a material-to-liquid ratio of 1:3, then continue heating to 80°C, keep for 2 hours, separate the decocted liquid, and continue to filter out the dregs Decoct 3 times until the flavor of the decoction becomes ...

Embodiment 2

[0076] A pain-dispelling ointment and a production process thereof, the production process comprising:

[0077] (1) Preparation of traditional Chinese medicine extract

[0078] The formula of traditional Chinese medicine extract is as follows: 150 parts of Vajra vine, 100 parts of papaya, 100 parts of leech, 100 parts of hemp seed, 100 parts of wood beetle, 100 parts of dried blood, 200 parts of Angelica dahurica, 100 parts of notopterygium, 100 parts of drynaria, 200 parts of Fangfeng, 100 parts of Cangzhu, 100 parts of Angelica, 150 parts of Sappan, 200 parts of Dipsacus, 150 parts of Chuanqiong, 200 parts of frankincense, 200 parts of myrrh, 150 parts of borneol;

[0079] After mixing the above raw materials, wash and grind them, then soak in hot water for 2 hours at a material-to-liquid ratio of 1:3, then continue heating to 80°C, keep for 2 hours, separate the decocted liquid, and continue to filter out the dregs Decoct 3 times until the flavor of the decoction becomes l...

Embodiment 3

[0092] A pain-dispelling ointment and a production process thereof, the production process comprising:

[0093] (1) Preparation of traditional Chinese medicine extract

[0094] The formula of traditional Chinese medicine extract is as follows: 160 parts of Vajra vine, 110 parts of papaya, 110 parts of leech, 110 parts of hemp seed, 110 parts of wood beetle, 110 parts of blood, 210 parts of Angelica dahurica, 110 parts of notopterygium, 110 parts of drynaria, 210 parts of Fangfeng, 110 parts of Cangzhu, 110 parts of Angelica, 160 parts of Sappan, 210 parts of Dipsacus, 160 parts of Chuanqiong, 210 parts of frankincense, 210 parts of myrrh, and 160 parts of borneol;

[0095] After mixing the above raw materials, wash and grind them, then soak in hot water for 2 hours at a material-to-liquid ratio of 1:3, then continue heating to 80°C, keep for 2 hours, separate the decocted liquid, and continue to filter out the dregs Decoct 3 times until the flavor of the decoction becomes lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com