Furnace sealing atmosphere purifying box

A purification box and atmosphere technology, which is applied in furnaces, furnace components, chemical instruments and methods, etc., can solve the problems of affecting the surface quality of parts, the oxidation of parts is very harmful, and the surface purification of parts is unfavorable, so as to achieve simple structure and good use effect. , Easy to disassemble, install and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

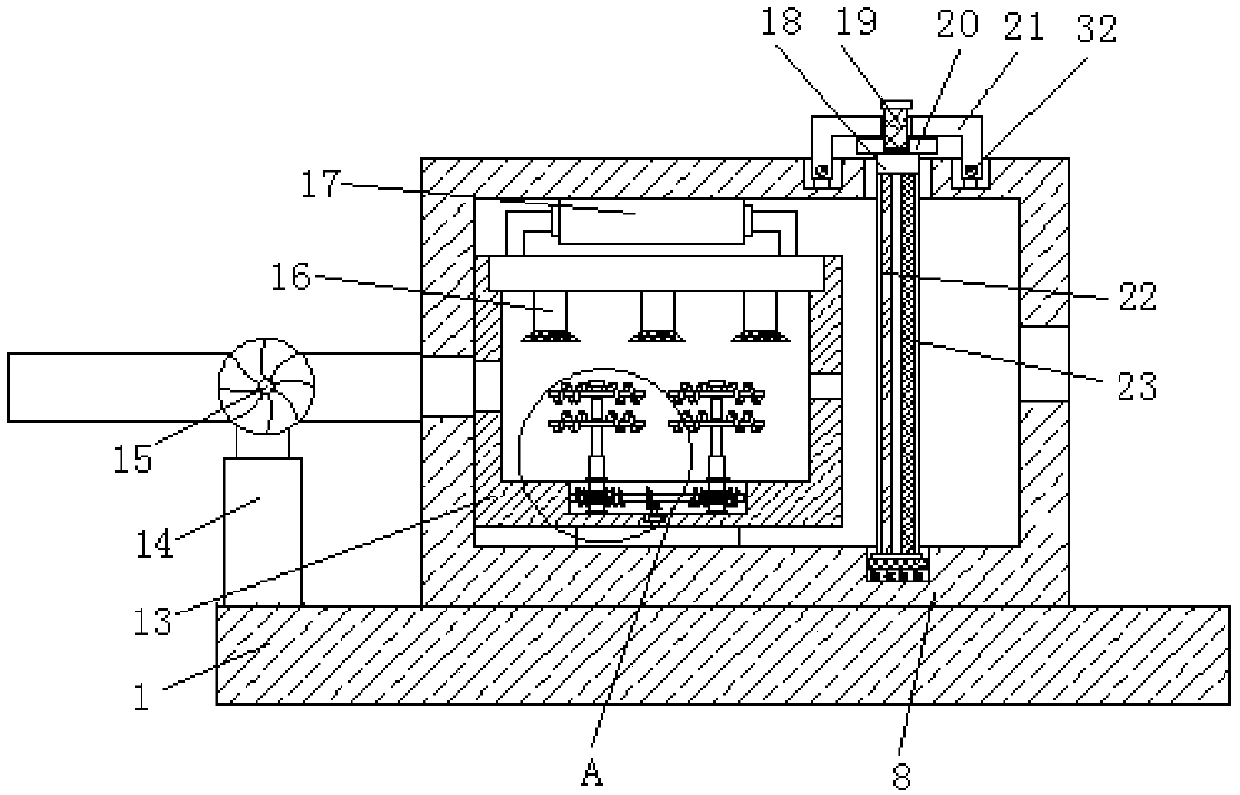

[0018] Embodiment 1: refer to Figure 1-3 , a furnace seal atmosphere purification box, including a base 1, the upper end of the base 1 is fixedly connected with a main box 8, the two sides of the main box 8 are respectively provided with an air inlet channel and an air outlet channel, and the upper end of the base 1 is fixedly connected with a support The rod 14 is fixedly connected with a suction fan 15 on the support rod 14. The suction fan 15 sucks the gas in the boiler through the conduit into the main box body 8. The suction fan 15 communicates with the air intake passage through the conduit. Fixedly connected with filter box 13, the inner bottom of main box body 8 is fixedly connected with ozone tank 17, and ozone tank 17 is fixedly connected with the upper end side wall of main box body 8, and the upper end side wall of main box body 8 is provided with ozone tank 17 The ventilation groove corresponding to the position, ozone filters the gas in the filter box 8, the low...

Embodiment 2

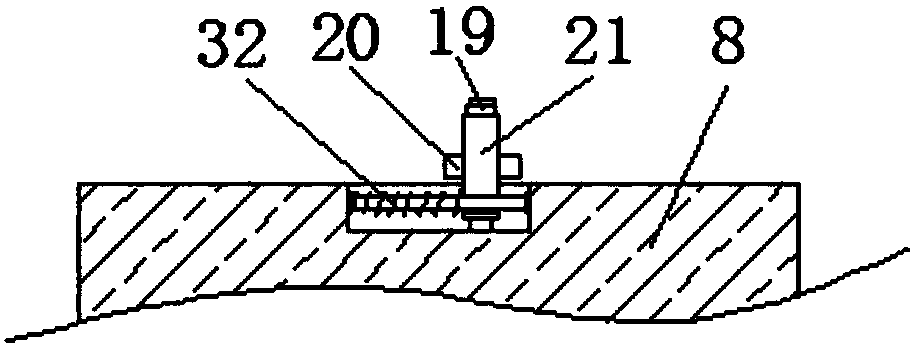

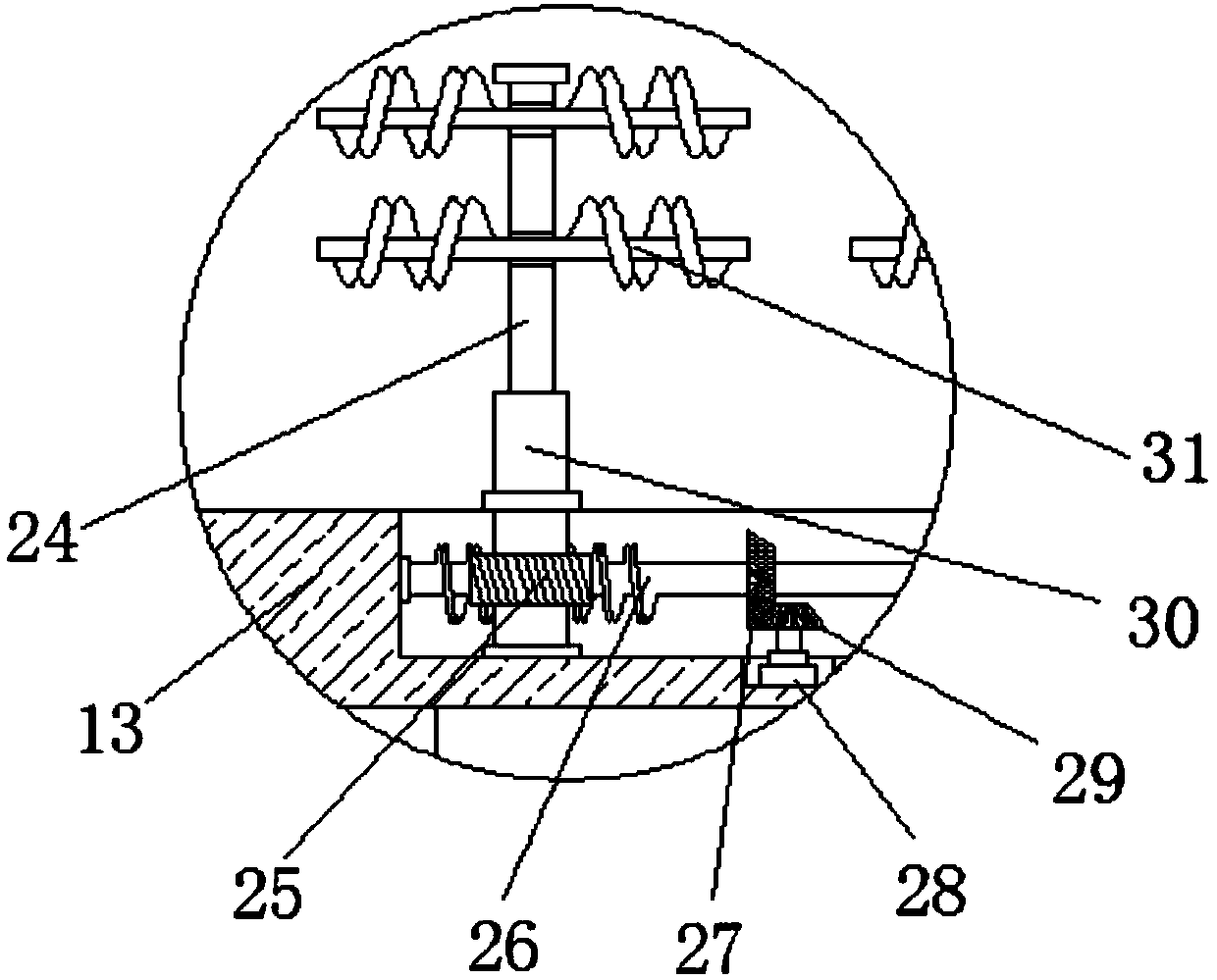

[0020] Embodiment 2: refer to Figure 2-5, applying the present invention to a furnace seal atmosphere purification device, comprising a base 1, the four corners of the lower end of the base 1 are provided with a running mechanism, the running mechanism is helpful for the movement and handling of the purification device, and the upper end of the base 1 is provided with a placement groove, The inner bottom of the placement slot is fixedly connected with a buffer pad 7, the buffer pad 7 plays the role of cushioning and shock absorption, and the upper end of the buffer pad 7 is fixedly connected with a sliding plate 9, and both sides of the placement slot are provided with corresponding to the position of the sliding plate 9. The movable groove is provided with a sliding mechanism, the two ends of the sliding plate 9 are fixedly connected with the sliding mechanism, the sliding plate 9 slides in the sliding groove, the upper end of the sliding plate 9 is provided with the main box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com