Full-automatic packing clasp forming machine

A molding machine and fully automatic technology, applied in the field of packing buckles, can solve the problems of being unable to adapt to automatic production, low production efficiency, complicated operation, etc., and achieve the effect of simple structure, high production efficiency and continuous processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

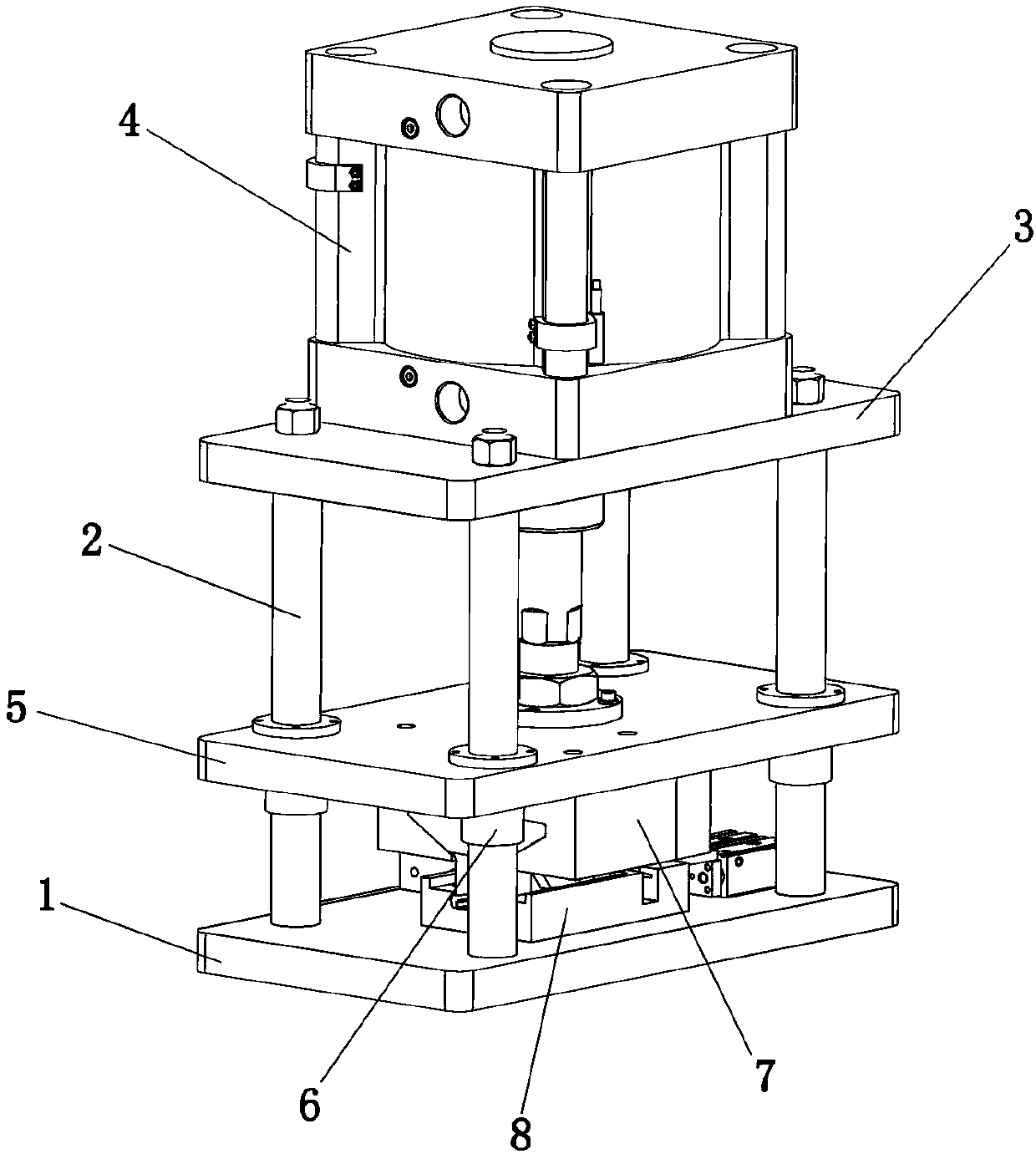

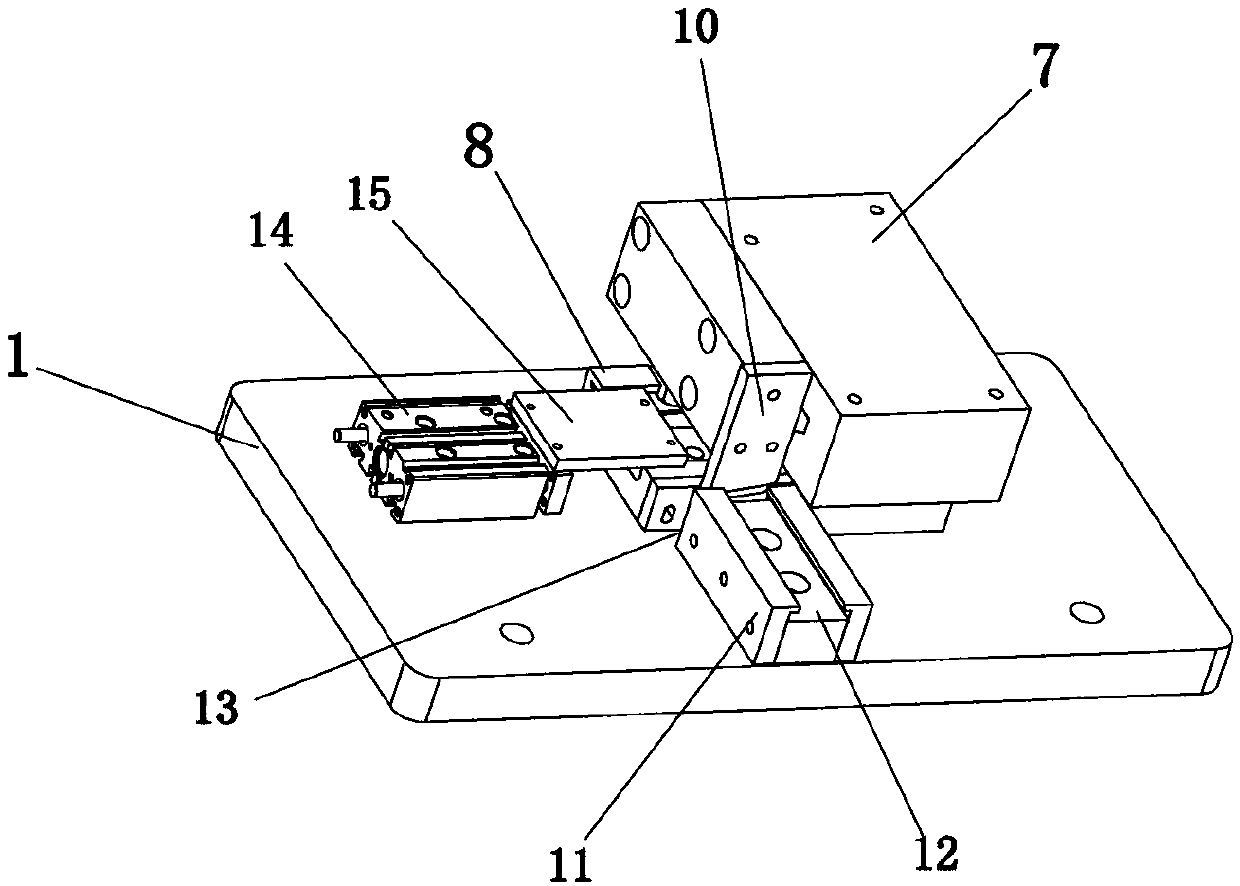

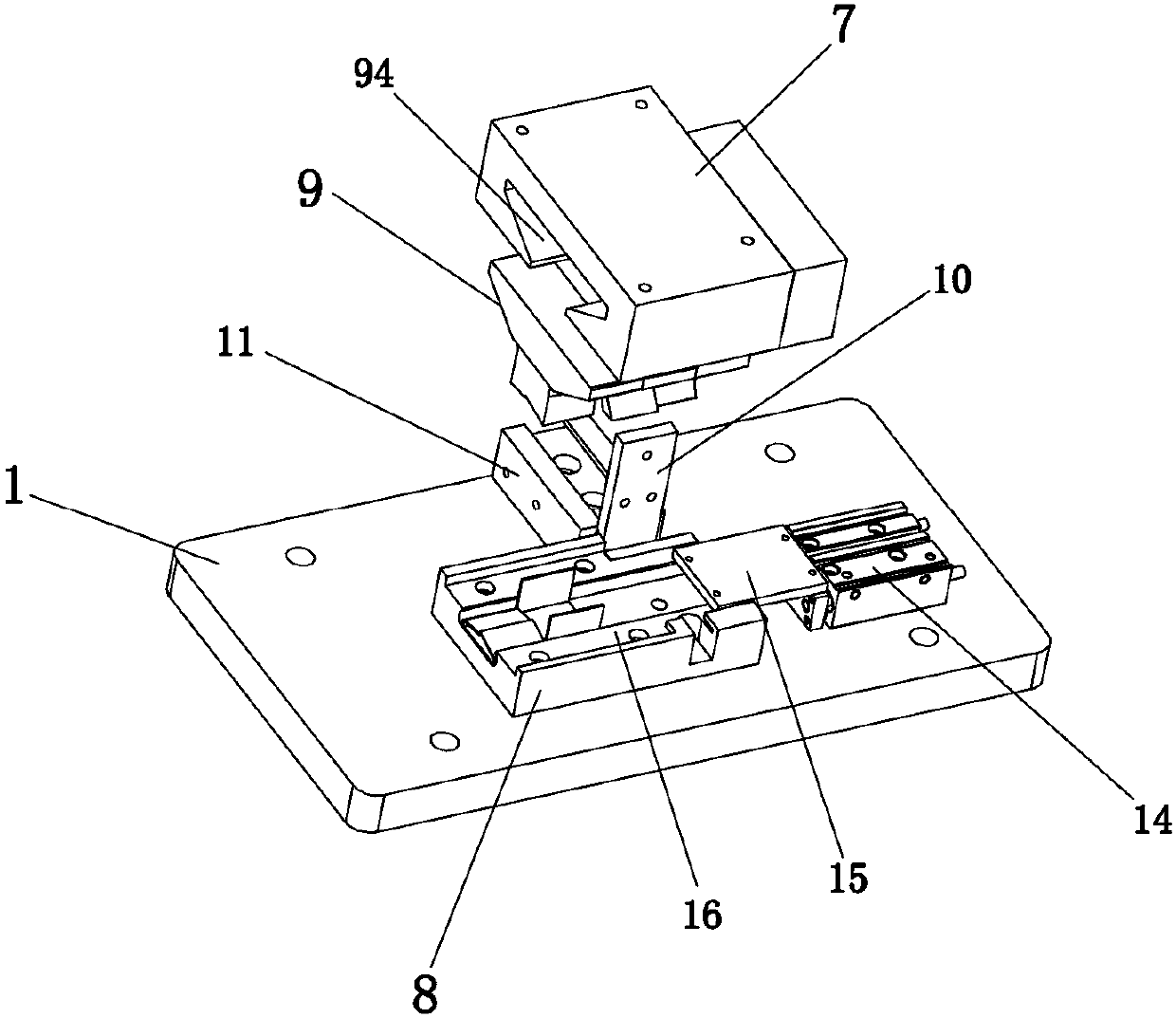

[0023] A fully automatic packing button forming machine, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a base plate 1, the base plate 1 is provided with a forming mechanism, the base plate 1 is connected with a top plate 3 through a slide bar 2, and the top plate 3 is provided with a lift cylinder 4, and the piston rod of the lift cylinder 4 A pressing plate 5 is connected to it; the forming mechanism is connected with the pressing plate 5; the forming mechanism includes a fixed seat 7 and a forming seat 8, the fixed seat 7 is connected with the pressing plate 5, and a forming mold is provided on the fixed seat 7 Group 9; the fixed seat 7 is provided with a cutter 10; the forming seat 8 is arranged on the bottom plate 1, and the forming seat 8 is located directly below the forming die group 9; the side of the forming seat 8 is provided with a feeding Seat 11, the side of described forming seat 8 is provided with pushing material cylinder 14, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap