Preparation method and intermediate of Pazopanib

A system and compound technology, applied in the field of medicine and chemical industry, can solve the problems of harsh reaction conditions, high industrialization cost, complicated purification operation, etc., achieve the effect of mild reaction conditions, reduce the generation of by-products, and simplify the purification operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

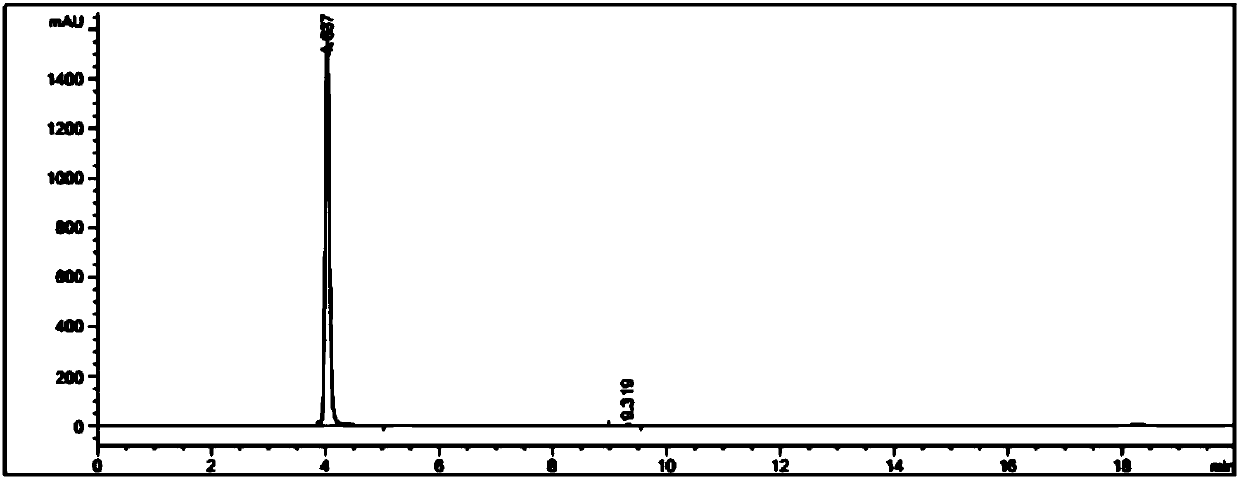

Image

Examples

Embodiment 1

[0036] Embodiment 1: the synthesis of formula 2 compound

[0037]

[0038] The compound of formula 7, triphenylphosphine, dichloromethane and dichlorodicyanobenzoquinone are added to the reaction flask, and methanol is added dropwise to the reaction solution. After the reaction is completed, an aqueous solution of sodium thiosulfate is added, and the layers are separated and organic The phase was washed with saturated brine, then methanol was added, the temperature was lowered to 0°C, and after stirring for 1-2 hours, the precipitated solid was the compound of formula 2 with a yield of 94%. 1H NMR (300MHz, d 6 DMSO) δ=8.53(s,1H),7.87(d,J=9.1Hz,1H),7.70(d,J=8.9,1H),4.26(s,3H),3.73(s,3H),2.61( s, 3H); MS (m / z) [M+H]+calcd for C10H14N3 176.1, found 176.3; white solid.

Embodiment 2

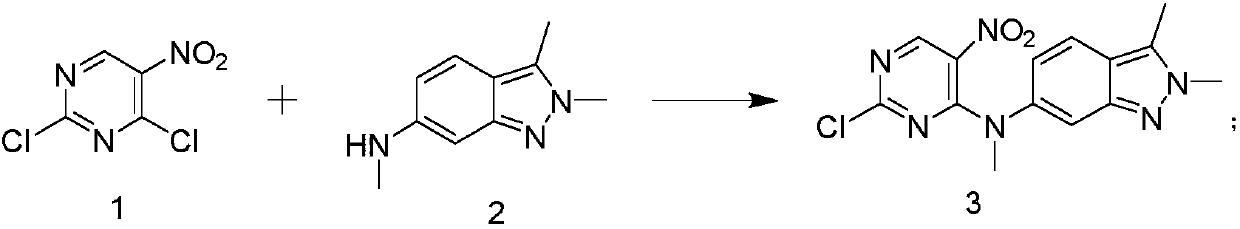

[0039] Embodiment 2: the synthesis of formula 3 compound

[0040]

[0041] Add 5.0 g of 2,4-dichloro-5-nitropyrimidine, compound of formula 2 (0.95 eq), diisopropylethylamine and 100 mL of toluene into the reaction flask at room temperature, heat, and react 4- 6 hours, controlled by TLC, after the reaction was completed, washed with saturated brine, dried with anhydrous sodium sulfate, concentrated under reduced pressure, cooled to 0-5°C, added methyl tert-butyl ether under stirring, there was Solids were precipitated, and the stirring was continued at this temperature for 30 minutes, filtered, and dried to obtain the compound of formula 3 with a yield of 92%. 1H NMR (300MHz, d 6 DMSO) δ=10.2(s,1H),7.32(d,J=9.0Hz,1H),6.36(d,J=8.8,1H),6.29(s,1H),3.76(s,3H),3.57( s,3H), 2.39(s,3H); MS (m / z) [M+H]+calcd for C14H14ClN6O2 333.1, found 333.3.

Embodiment 3

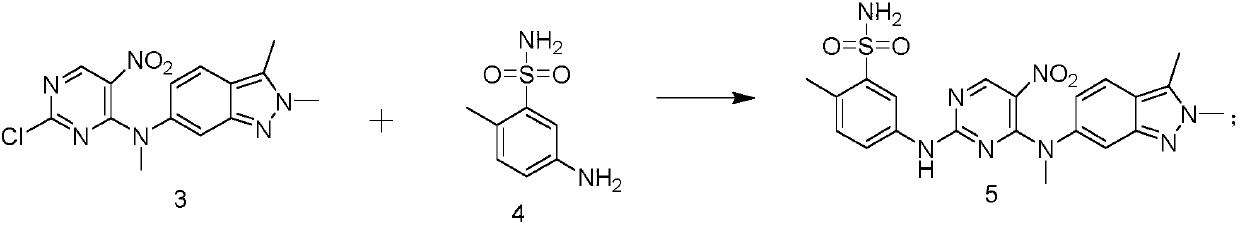

[0042] Embodiment 3: the synthesis of formula 5 compounds

[0043]

[0044] Add the compound of formula 3, the compound of formula 4, diisopropylethylamine and 100mL of methanol into the reaction flask at room temperature, heat up to 60°C, and react at this temperature for 4-8 hours, control in TLC, after the reaction is completed , concentrated under reduced pressure, washed with saturated brine, dried with anhydrous sodium sulfate, cooled to 0-5 °C, added methyl tert-butyl ether under stirring, solids were precipitated, and continued to stir at this temperature for 30 minutes, filtered and dried to obtain compound 5 with a yield of 87%. 1H NMR (300MHz, d 6 DMSO)δ=10.1(s,1H),7.81(d,J=6.2Hz,1H),7.67-7.71(m,2H),7.36(s,1H),7.32-7.26(m,2H),6.36( d,J=8.8,1H),6.29(s,1H),4.07(s,3H),3.76(s,3H),3.57(s,3H),2.39(s,3H);[M+H]+ calcd for C21H23N8O4S, 483.1, found 483.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com