A kind of surface hydrophobic metal organic framework material and its preparation and application

A metal-organic framework and hydrophobic technology, applied in the chemical field, can solve problems such as water stability, and achieve the effects of reduced adhesion, high BET specific surface area, and good channel performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Synthesis of ZIF-90 Containing 1% Aminooctadecane

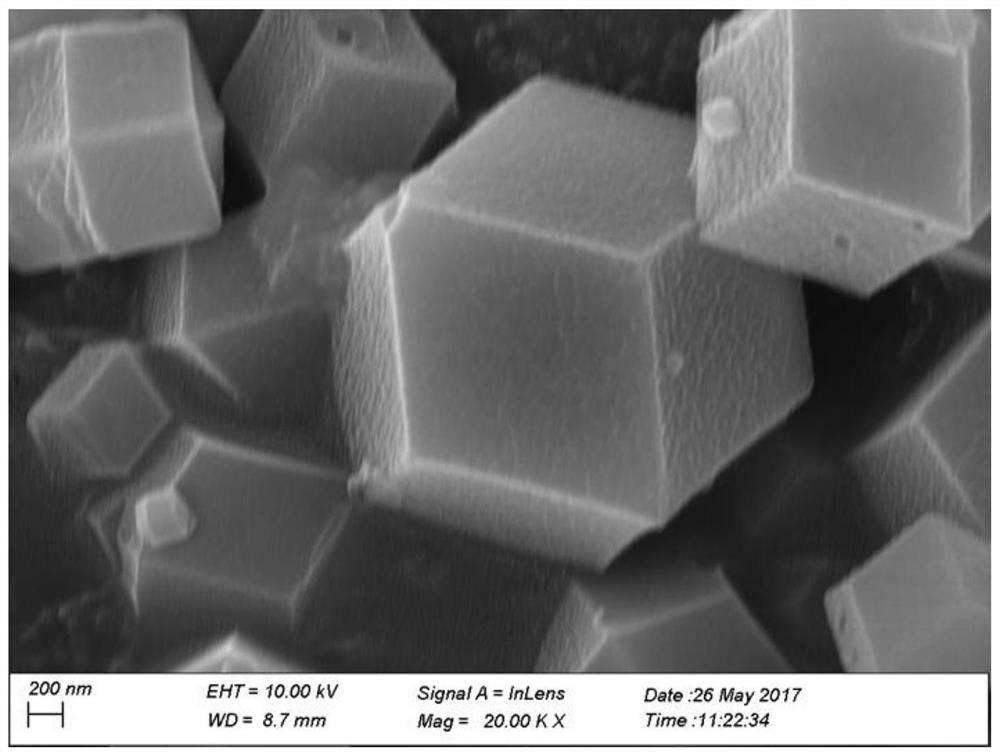

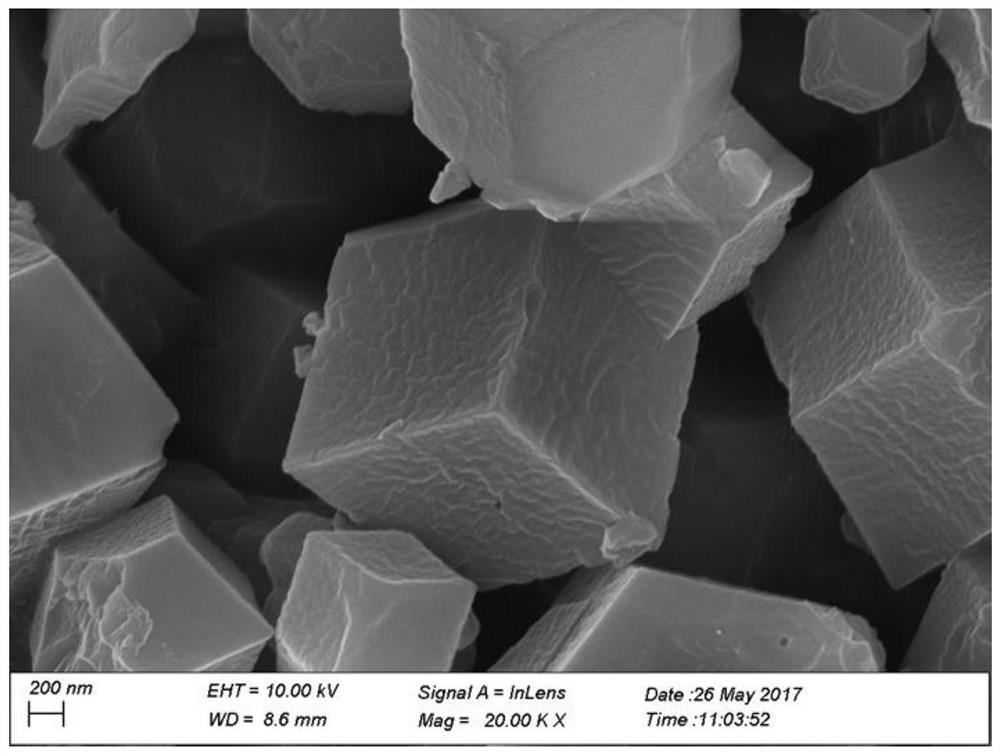

[0044] Add 20 mmol 2-imidazole formaldehyde and 5 mmol zinc nitrate hexahydrate to 100 mL DMF, heat to 80°C, stir at 600 r / min, add 50 mL water, collect the precipitate half an hour later, and obtain the scanning electron microscope of the precipitate The result is as figure 1shown. Transfer the precipitate to two 50 mL centrifuge tubes, and centrifuge at 8000 r / min. After the precipitate was washed with ethanol for 3 times, the precipitate was placed in a flask, 500 μL of aminooctadecyl ethanol solution (1.2 mmol / 50 mL) was added, and the reaction was heated for 4 hours to collect the solid product. The solid product was washed with ethanol and activated in vacuum at 150°C to obtain ZIF-90 containing 1% aminooctadecane. The scanning electron microscope results were as follows: figure 2 shown.

Embodiment 2

[0046] Synthesis of ZIF-90 Containing 5% Aminooctadecane

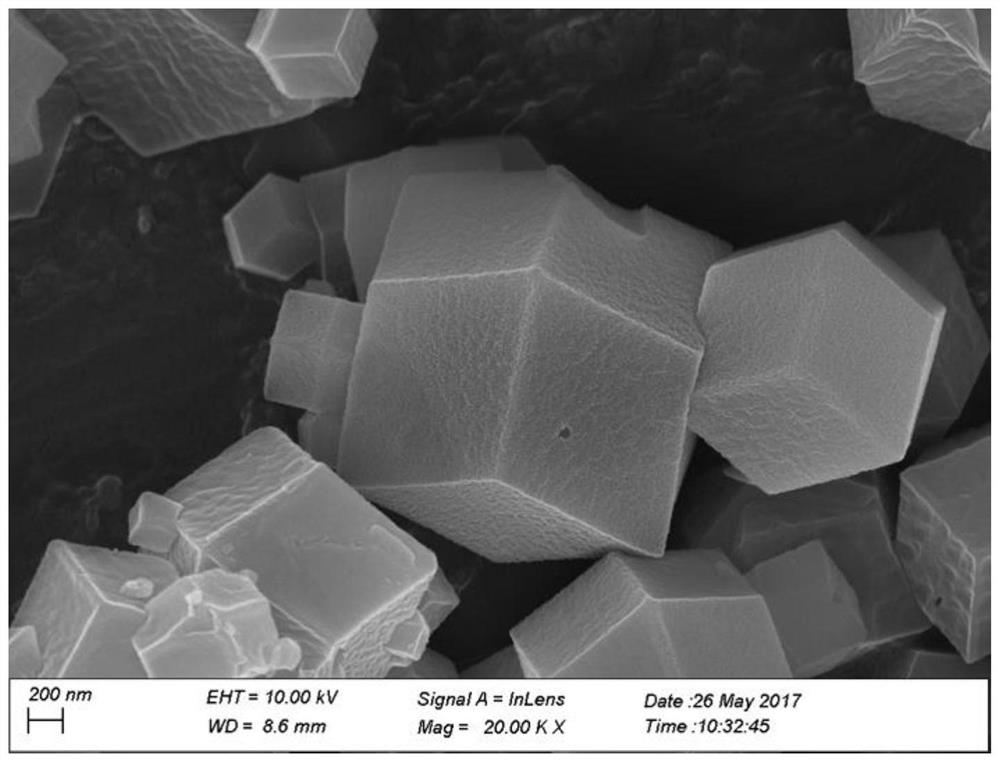

[0047] Add 20 mmol of 2-imidazole formaldehyde and 5 mmol of zinc nitrate hexahydrate into 100 mL of DMF, heat to 80°C, stir at 600 r / min, add 50 mL of water, and collect the precipitate after half an hour. Transfer the precipitate to two 50mL centrifuge tubes, and centrifuge at 8000 r / min. After the precipitate was washed with ethanol for 3 times, the precipitate was placed in a flask, 2.5 mL of aminooctadecane ethanol solution (1.2 mmol / 50 mL) was added, the reaction was heated for 4 hours, and the solid product was collected. The solid product was washed with ethanol, and vacuum activated at 150°C to obtain ZIF-90 containing 5% aminooctadecane. The scanning electron microscope results were as follows: image 3 shown.

Embodiment 3

[0049] Synthesis of ZIF-90 Containing 10% Aminooctadecane

[0050] Add 20 mmol of 2-imidazole formaldehyde and 5 mmol of zinc nitrate hexahydrate into 100 mL of DMF, heat to 80°C, stir at 600 r / min, add 50 mL of water, and collect the precipitate after half an hour. Transfer to two 50mL centrifuge tubes and centrifuge at 8000 r / min. After the precipitate was washed with ethanol for 3 times, the precipitate was placed in a flask, 5 mL of aminooctadecane ethanol solution (1.2 mmol / 50 mL) was added, the reaction was heated for 4 hours, and the solid product was collected. The solid product was washed with ethanol, and vacuum activated at 150°C to obtain ZIF-90 containing 10% aminooctadecane. The scanning electron microscope results were as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com