A three-phase electrostatic coalescence separator for oil, gas and water

An electrostatic coalescence and separator technology, applied in the field of multiphase separation of oil and gas gathering and transportation systems, can solve the problems of no water layer monitoring system, increased risk, and easy electrode breakdown, etc. Breakdown problems, effects that increase the chance of collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

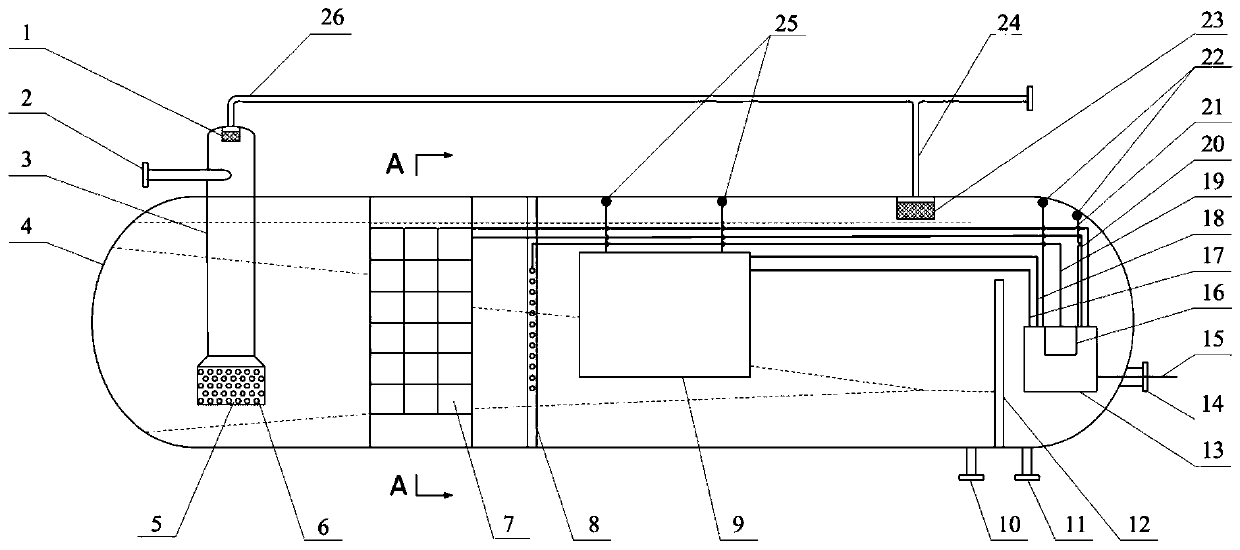

[0040] Such as figure 1 As shown, an oil-gas-water three-phase electrostatic coalescence separator, including a separator main body, a gas-liquid separation module, a high water content coalescence module, a low water content coalescence module, a power supply and a control system;

[0041] The main body of the separator includes a horizontal cylinder 4, a weir plate 12 is vertically arranged on the right side of the horizontal cylinder 4, and a water outlet 10 is arranged at the bottom of the horizontal cylinder 4 on the left side of the weir plate 12. The bottom of the horizontal cylinder 4 on the right side of the plate 12 is provided with an oil outlet 11; the right end of the horizontal cylinder 4 is provided with a cable lead hole 14;

[0042] The gas-liquid separation module is vertically inserted into the left side of the horizontal cylinder 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com