Novel nozzle rotational flow structure and nozzle structure

A new type of spiral technology, applied in the field of coal gasification, can solve the problem that the DC impingement pulverized coal burner cannot meet various process requirements, achieve good atomization effect and improve economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

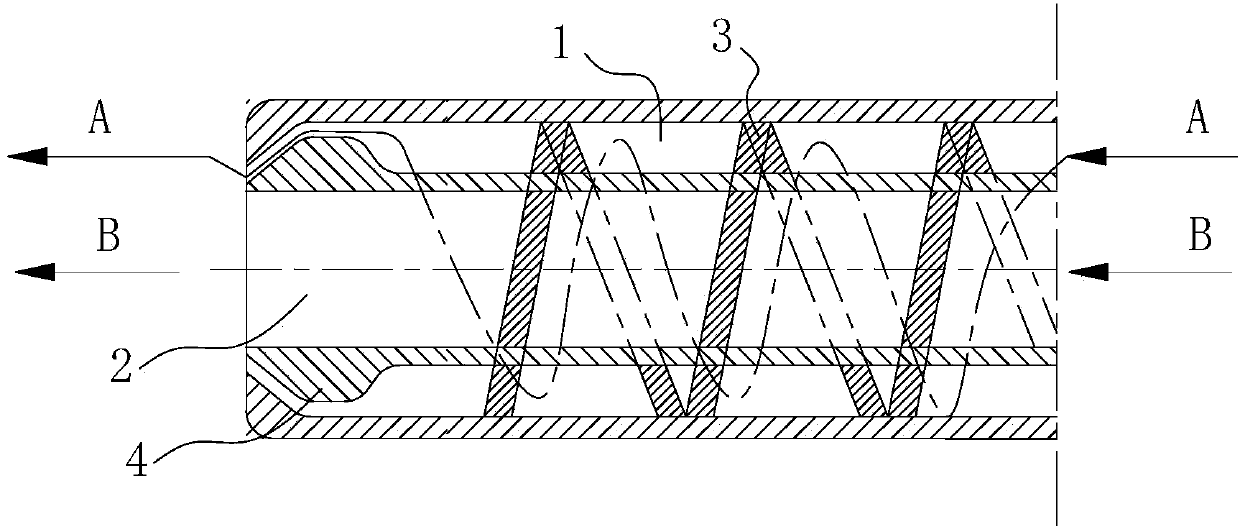

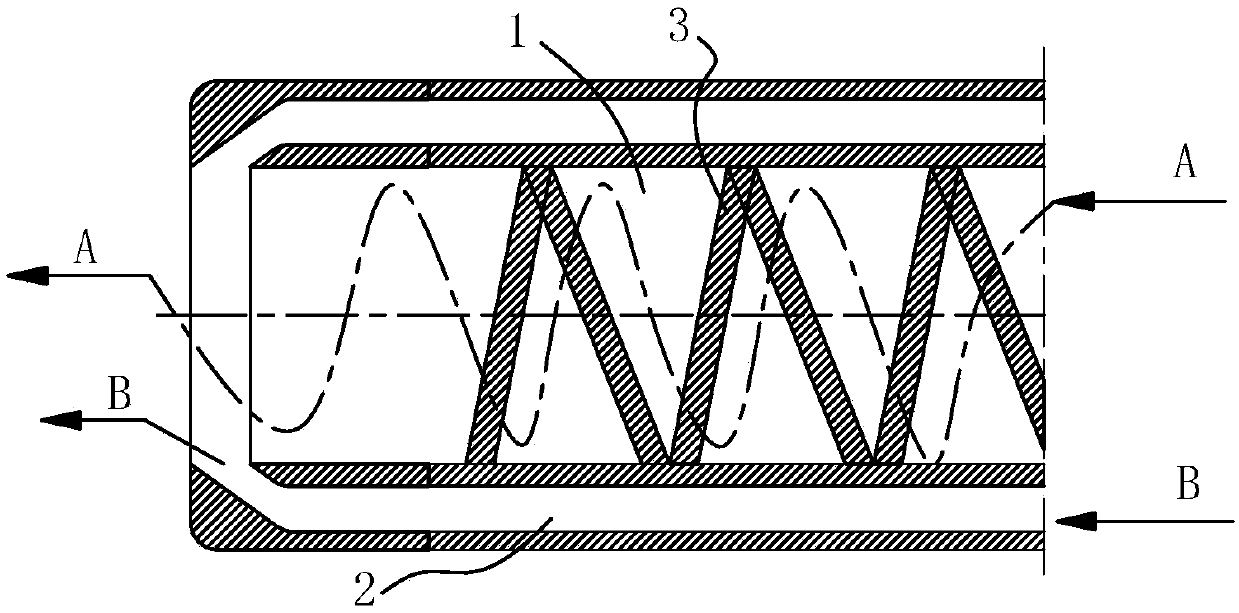

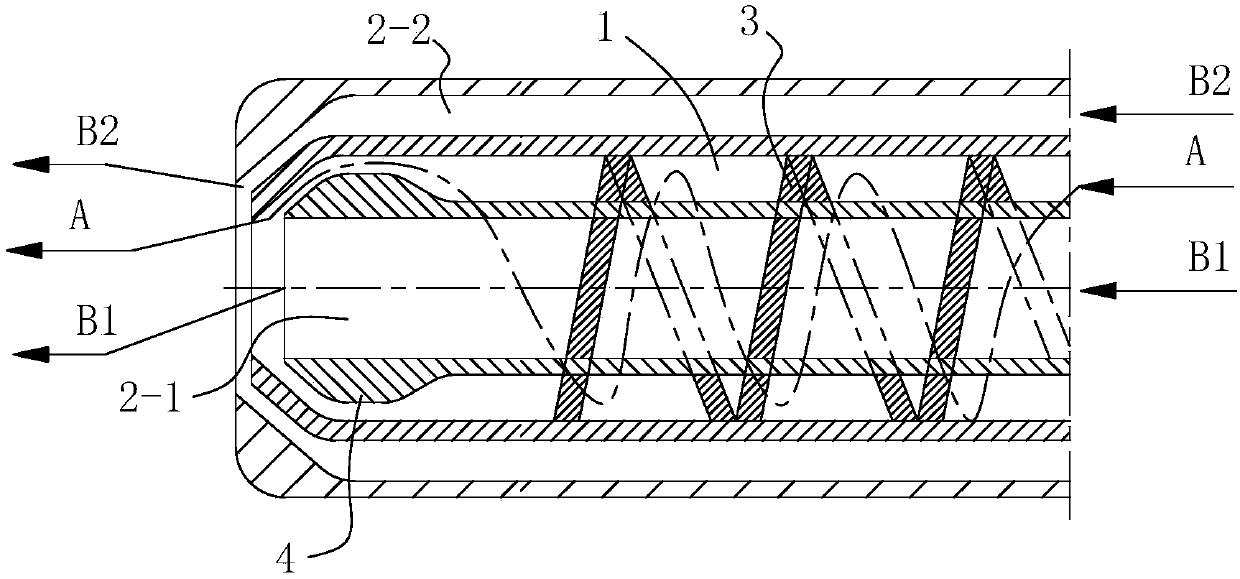

[0022] see Figure 1-Figure 3 , the present invention first proposes a novel burner swirl structure, which is specifically: a spiral partition 3 capable of rotating and flowing the combustion medium A is provided on the inner wall of the combustion medium passage 1 in the burner, because the combustion medium A It has a strong wear and corrosion effect on the partition, so the spiral partition 3 is a wear-resistant and corrosion-resistant spiral strip plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com