Thermal transfer paper production and processing system

A processing system, a technology for thermal transfer paper, applied in papermaking, papermaking, textiles and papermaking, etc., can solve problems such as appearance differences, hinder the production output of paper materials, etc., and achieve the effect of increasing quantity, increasing compactness, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

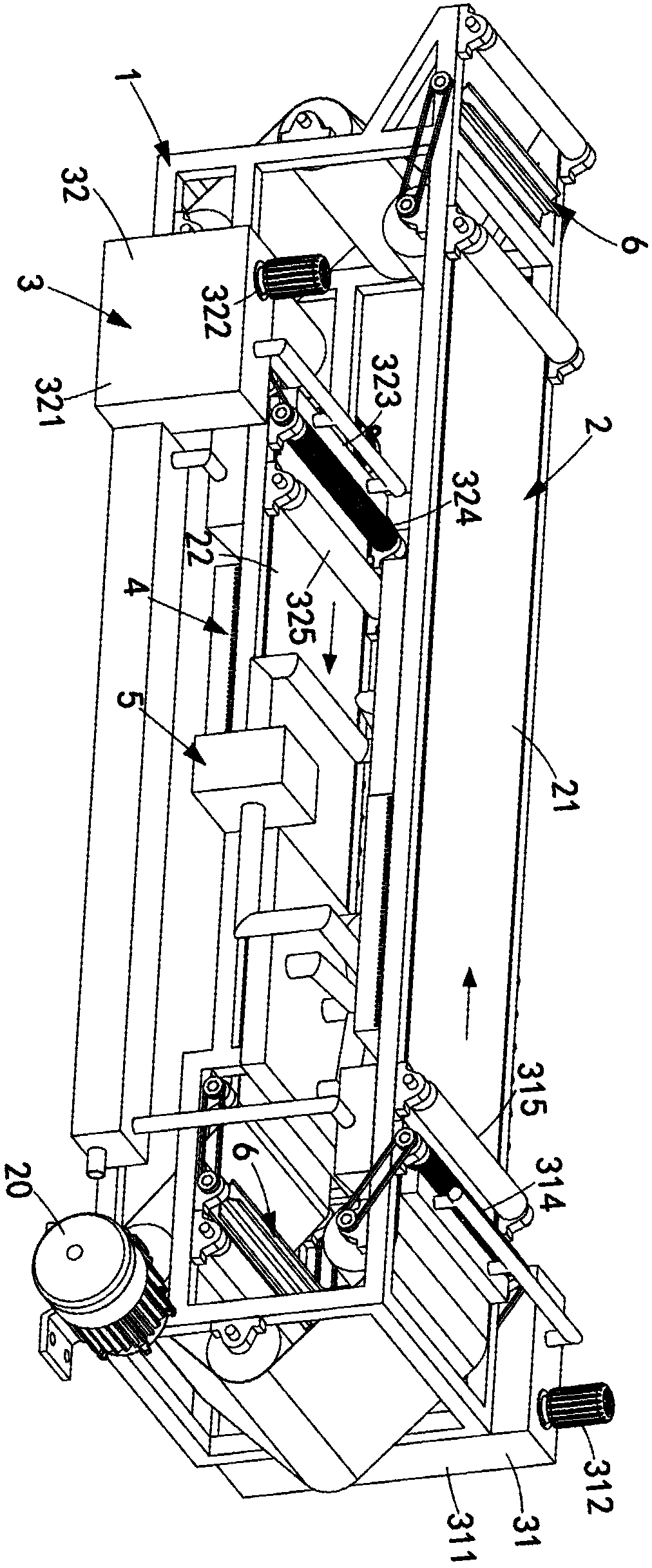

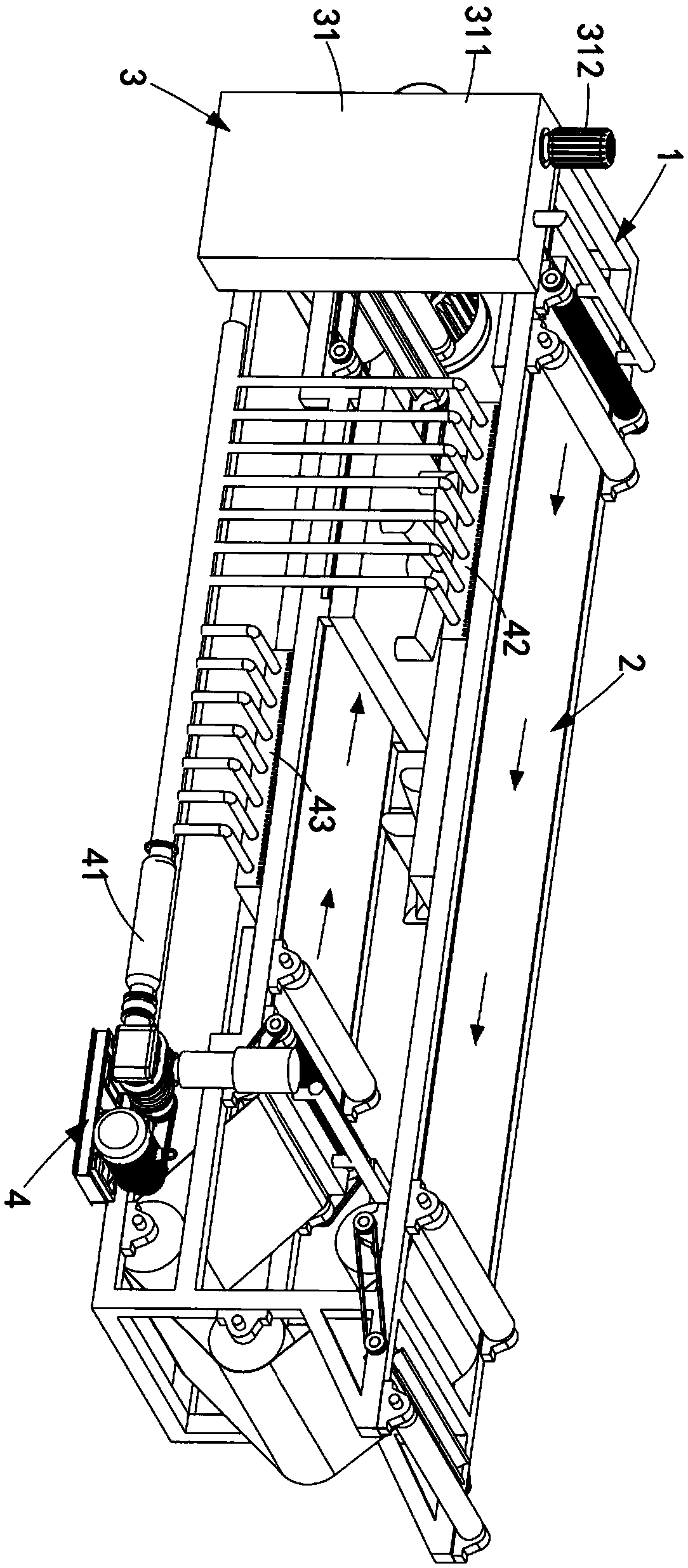

[0060] Such as figure 1 and figure 2 As shown, a thermal transfer paper production and processing system includes a frame 1, which is set in a frame shape, and also includes:

[0061] The forming wire 2, the forming wire 2 is rotatably arranged on the frame 1 to form an endless wire loop, which includes a first forming area 21 on the upper part and a second forming area 22 on the lower part, the first forming area 21 and the second forming area 22 The two ends of the two forming areas 22 are connected by a turning area 23, and the input end of the first forming area 21 is located above the output end of the second forming area 22, and the output end of the first forming area 21 is located in the second forming area. Above the input end of the second shaping zone 22;

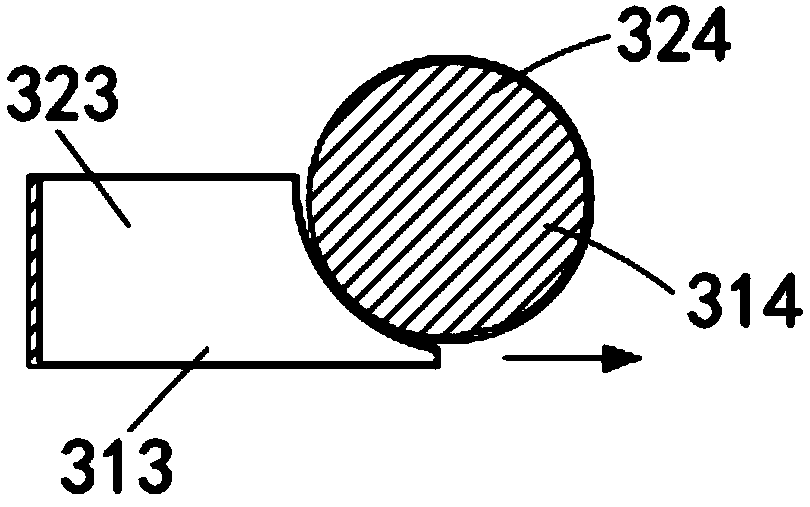

[0062] The feeding mechanism 3, the feeding mechanism 3 is located on both sides of the frame 1, it includes a first feeding assembly 31 and a second feeding assembly 32, the first feeding assembly 31 is oppos...

Embodiment 2

[0100] Figure 10 It is a structural schematic diagram of Embodiment 2 of a thermal transfer paper production and processing system of the present invention; as Figure 10 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0101] Such as Figure 10 As shown, a thermal transfer paper production and processing system also includes a swing paddle 6, the swing paddle 6 is respectively arranged at the output ends of the first forming area 21 and the second forming area 22, and the two ends of the swing paddle 6 It is rotatably arranged on the frame 1, and there are several paddles 61 arrayed along the axial circumference of the oscillating paddle 6, and the outer ends of the paddles 61 are arranged smoothly.

[0102] I...

Embodiment 3

[0104] Figure 11 It is a schematic structural diagram of Embodiment 3 of a thermal transfer paper production and processing system of the present invention; as Figure 11 As shown, the parts that are the same as or corresponding to those in Embodiment 1 use the reference numerals corresponding to Embodiment 1. For the sake of simplicity, only the differences from Embodiment 1 will be described below. This embodiment two and figure 1 The difference of the shown embodiment one is:

[0105] Such as Figure 11 As shown, a heat transfer paper production and processing system also includes a waste water recovery device 7, and the waste water recovery device 7 includes:

[0106] A waste water tank 71, the waste water tank 71 is arranged at the input end of the first forming area 21 and the second forming area 22, and the waste water tank 71 is respectively located at the first spreading roller 314 and the first smoothing roller 315 and Below the second spreading roller 324 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com