Using and constructing method of decorative and fireproof integrated plate

A construction method and technology of fire retardant coatings, applied in building construction, covering/lining, construction, etc., can solve the problems of affecting appearance, easy to fall off, affecting the fire protection function of fire retardant coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

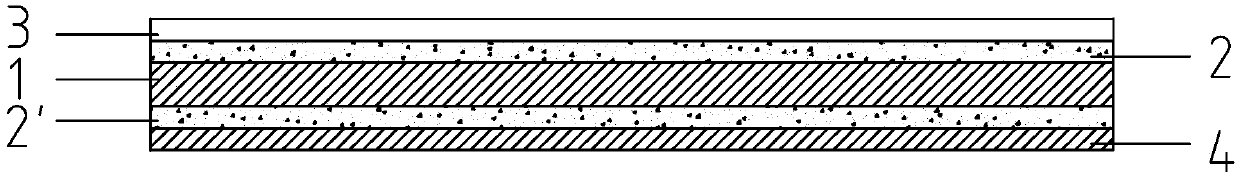

[0025] like figure 1 Shown: the structure of a decorative and fireproof integrated board is as follows: one side surface of the metal plate substrate 1 is coated with the first anti-corrosion primer 2 and the top coat 3 in sequence; A second anti-corrosion primer 2' and a fire-resistant coating 4 are applied.

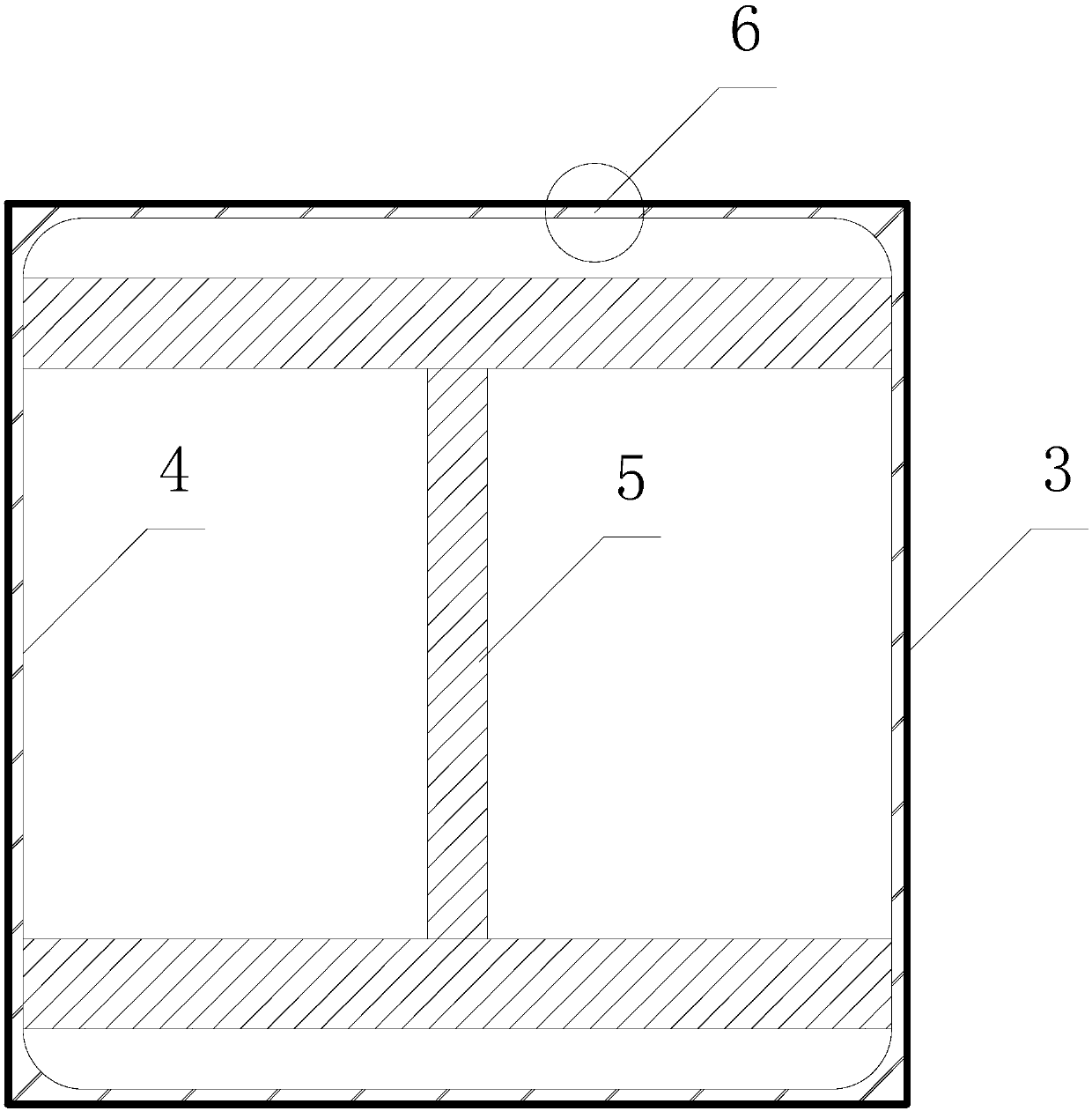

[0026] like figure 2 As shown: the decorative and fireproof integrated board of the present invention is wrapped on the outside of the steel member 5 when used, and the coated fireproof paint 4 is located inside. As an example, the shape of the steel member 5 is only a schematic.

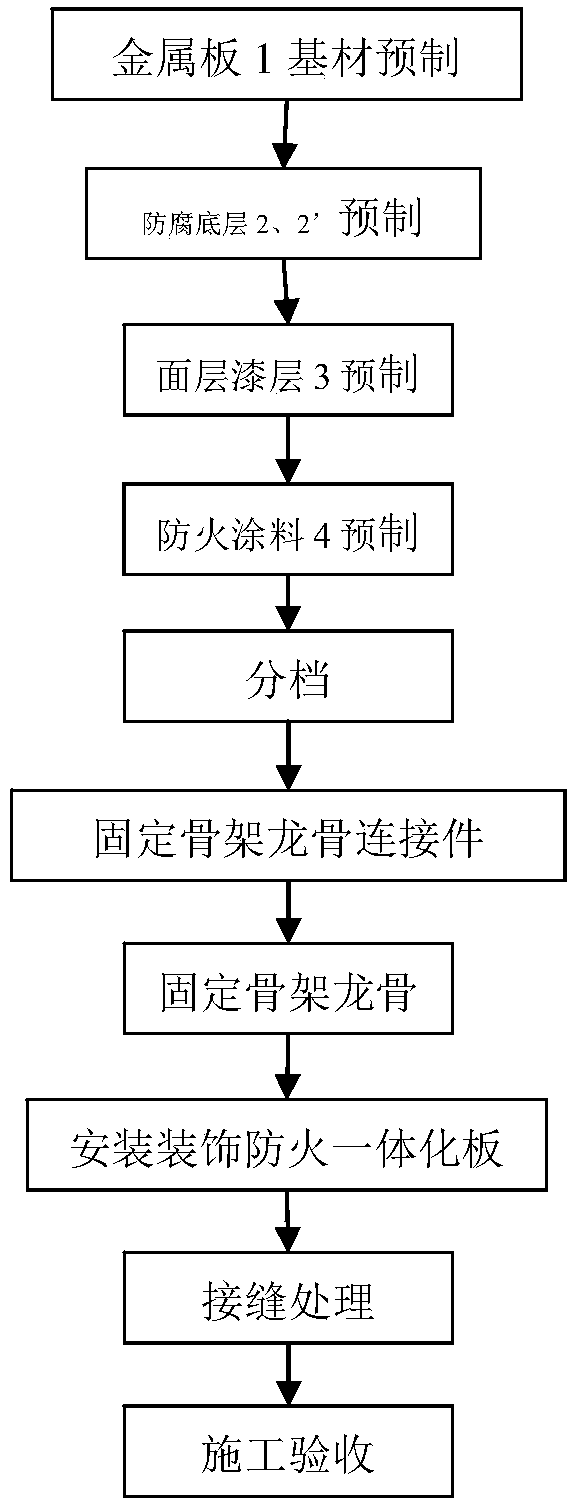

[0027] Generally, the construction process is as follows (such as image 3 shown):

[0028] 1. Prefabrication of the metal plate base material 1: According to the size and position of the steel structural members that need fire protection, select the plate type and size, and process the metal plate 1 base material in the factory in advance.

[0029] 2. Prefabricate the first and second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com