Mason knife for easy filling of wall mud

A wall mud and mud tile technology, applied in the field of building construction tools, can solve the problems of complicated operation, wall pollution, skin damage, etc., and achieve the effects of improving work efficiency, reducing labor intensity, and reducing physical damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

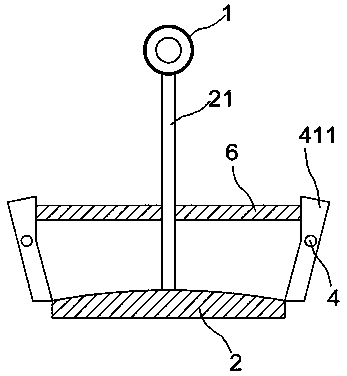

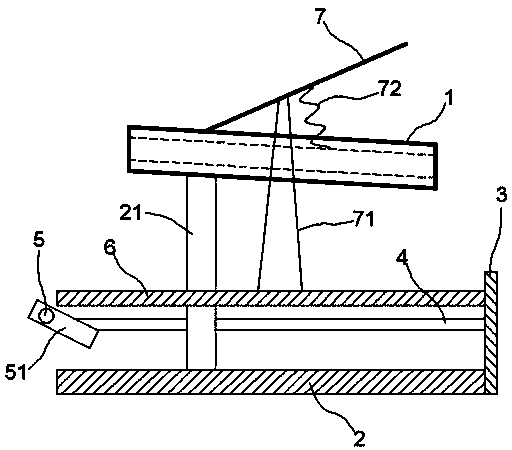

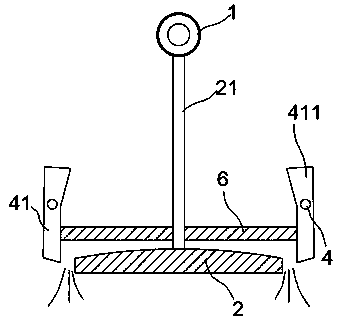

[0020] exist Figure 1 to Figure 4 In the shown embodiment, the masonry knife which is convenient for filling wall mud includes a handle 1 and a knife plate 2 placed horizontally, the upper surface of the knife plate 2 is arched upward; the handle 1 is fixed by a support rod 21 Installed on the upper surface of the knife plate 2; the gripping end of the handle 1 is lower than the front end, and the gripping end is rotated 10-15° downward from the horizontal direction;

[0021] A support plate 3 is fixedly installed on the rear end of the knife plate 2, and the support plate 3 is perpendicular to the knife plate 2; The front end is provided with a limited rotating shaft 5; the clamping rotating shaft 4, the limiting rotating shaft 5 and the support plate 3 are fixedly connected to form a frame;

[0022] Clamping plates 41 are sleeved on the two clamping shafts 4 respectively, a limiting plate 51 is set on the limiting rotating shaft 5 , and an extrusion parallel to the knife p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com