Repairing construction method for floor hollowing and cracking

A construction method and hollow technology, applied in building maintenance, construction, building construction, etc., can solve the problems of long time, large chromatic aberration of the floor, and many processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

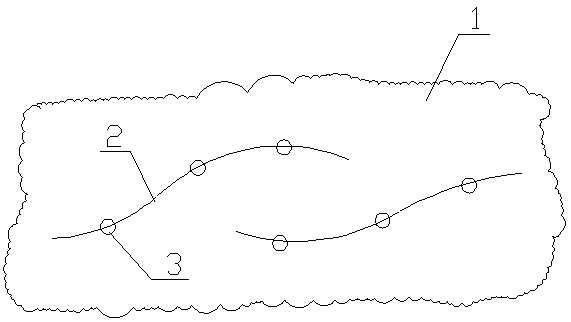

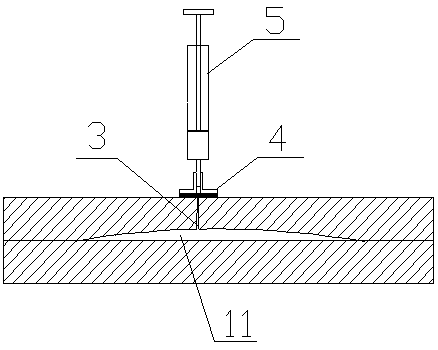

[0016] Example figure 1 and figure 2 Shown, the repairing construction method of floor hollow cracking of the present invention comprises the steps:

[0017] Step 1. Check and confirm the cracked part 1 of the hollow floor, remove the dust and oil on the surface of the crack 2, and keep the crack clean;

[0018] Step 2: Drill a number of grouting holes 3 at intervals of 200-550 mm at the cracked part 1 of the floor and clean them up. Embed grouting nozzles or grouting water-stop needles in the grouting holes 3 and use quick-drying sealant Seal the perimeter;

[0019] Step 3: Use quick-drying sealant to scrape along the crack 2 surface of the hollow cracked part 1 of the floor to seal the crack 2;

[0020] Step 4. The grouting nozzles 4 or the grouting water-stop needles of several grouting holes 3 are sequentially connected to the syringe 5, and the grouting resin solution is poured into the syringe 5, and the grouting resin solution is injected into the hollow cavity 11 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com